Chitosan-cellulose sulfate magnetic porous composite microsphere as well as preparation and application thereof

A technology of cellulose sulfate and porous composite microspheres, which is applied to the preparation method of peptides, microcapsules, alkali metal compounds, etc., can solve the problems of low mechanical strength, poor solubility of cellulose, limited adsorption capacity, etc., and the method is simple. , Improve solubility and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

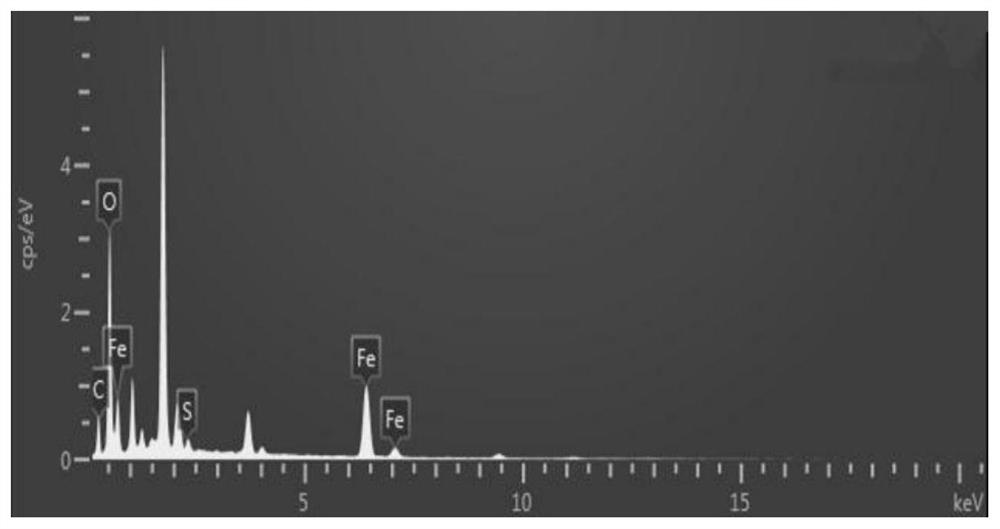

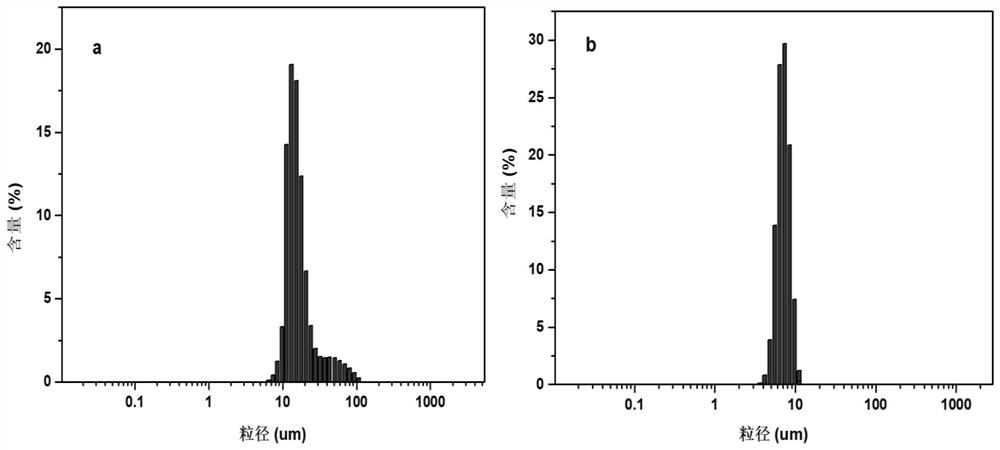

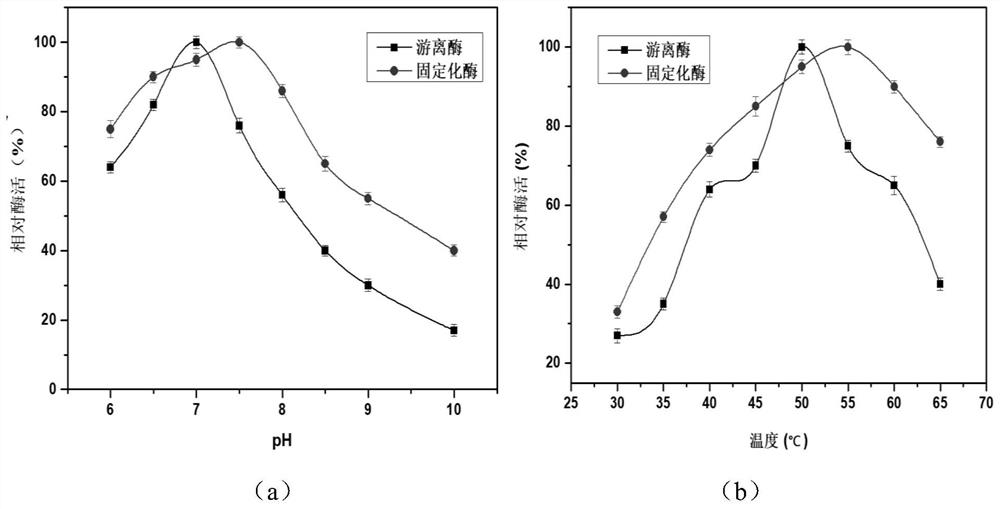

[0047] At the same time, chitosan and cellulose sulfate were added to 10 mL of 1-ethyl-3-methylimidazole acetate ([Emim] In Ac), under the condition of 80°C oil bath, magnetically stirred and dissolved at a speed of 250r / min for 1h, and a mixed solution of chitosan-cellulose sulfate-[Emim]Ac with a concentration of 3% (g / mL) was prepared ; Subsequently, the nano-Fe 3 o 4 Particles are added to the mixed solution, nano-Fe 3 o 4 The mass volume ratio of the mixed solution is 0.2g: 1mL, magnetically stirred at a speed of 500r / min for 30min to make it uniformly dispersed to obtain a magnetic suspension; then, the magnetic suspension (water phase) is dispersed in a volume ratio of 1:1: 1 In the emulsification system (oil phase) that is made up of liquid paraffin, Span-80 and sodium sulfate aqueous solution (the concentration of aqueous solution is 0.1g / mL), the water-oil ratio (the volume ratio of water phase and oil phase) is 1: 2. Stir magnetically in a 90°C oil bath at a spe...

Embodiment 2

[0051] At the same time, chitosan and cellulose sulfate were added to 10 mL of 1-ethyl-3-methylimidazole acetate ([Emim]Ac) at a mass ratio of 1:1, and at 90°C in an oil bath, With magnetic stirring and dissolving at a speed of 250r / min for 2h, a mixed solution of chitosan-cellulose sulfate-[Emim]Ac with a concentration of 2% was prepared; subsequently, the nano-Fe 3 o 4 Particles are added to the mixed solution, nano-Fe 3 o 4 The mass volume ratio to the mixed solution is 0.2g:1mL, and magnetically stirred at a speed of 500r / min for 1h to disperse evenly to obtain a magnetic suspension. Then, the magnetic suspension (water phase) was dispersed in an emulsification system (oil phase) composed of liquid paraffin, Span-80 and aqueous sodium sulfate (the concentration of the aqueous solution was 0.2 g / mL) at a volume ratio of 1:1:1. ), the water-to-oil ratio was 1:4, and magnetically stirred in a 90°C oil bath at a speed of 1000r / min for 1h; then, twice the volume of absolute ...

Embodiment 3

[0055] At the same time, chitosan and cellulose sulfate were added to 10 mL of 1-ethyl-3-methylimidazolium acetate ([Emim]Ac) at a mass ratio of 4:1, and at 100 °C in an oil bath, With magnetic stirring and dissolving at a speed of 250r / min for 3h, a mixed solution of chitosan-cellulose sulfate-[Emim]Ac with a concentration of 5% was prepared; subsequently, the nano-Fe 3 o 4 Particles are added to the mixed solution, nano-Fe 3 o 4 The mass volume ratio of the mixed solution is 0.2g: 1mL, magnetically stirred at a speed of 500r / min for 3h to make it uniformly dispersed to obtain a magnetic suspension; then, the magnetic suspension (water phase) is dispersed in a volume ratio of 1:1: 1 In the emulsification system (oil phase) composed of liquid paraffin, Span-80 and aqueous sodium sulfate solution (the concentration of the aqueous solution is 0.3g / mL), the water-oil ratio is 1:6, and the rotation speed is 1000r / min at 90 ℃ in an oil bath with magnetic stirring for 1 h; then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com