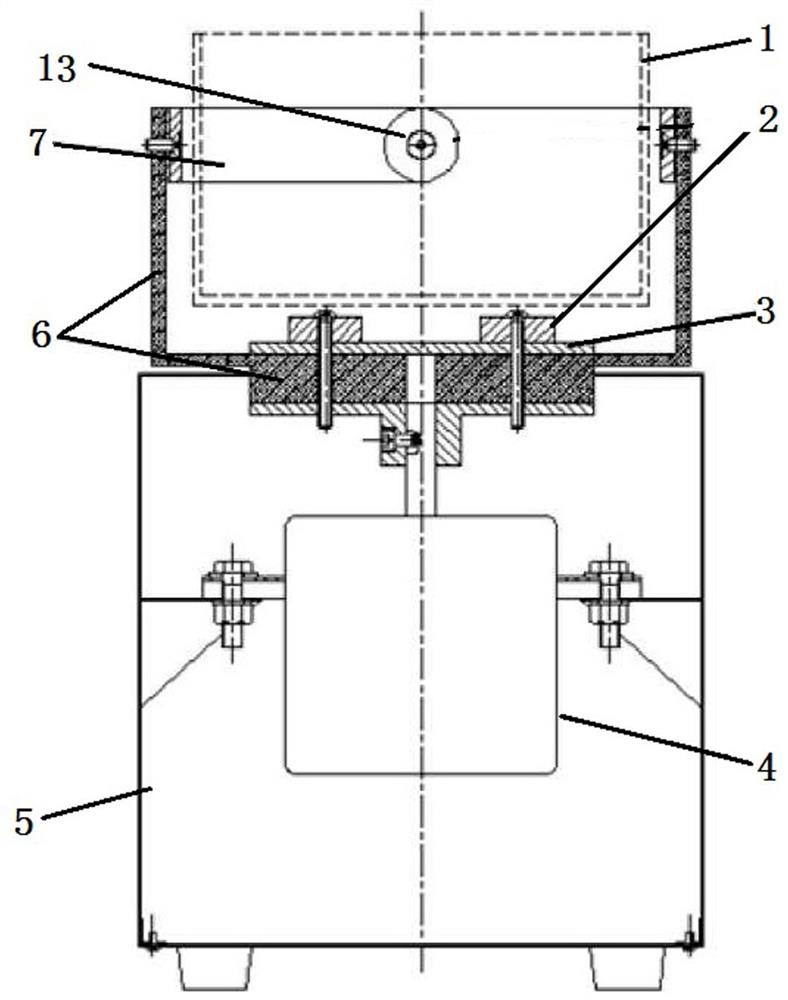

Ultra-high-speed rotating cylinder type permanent magnet polishing device

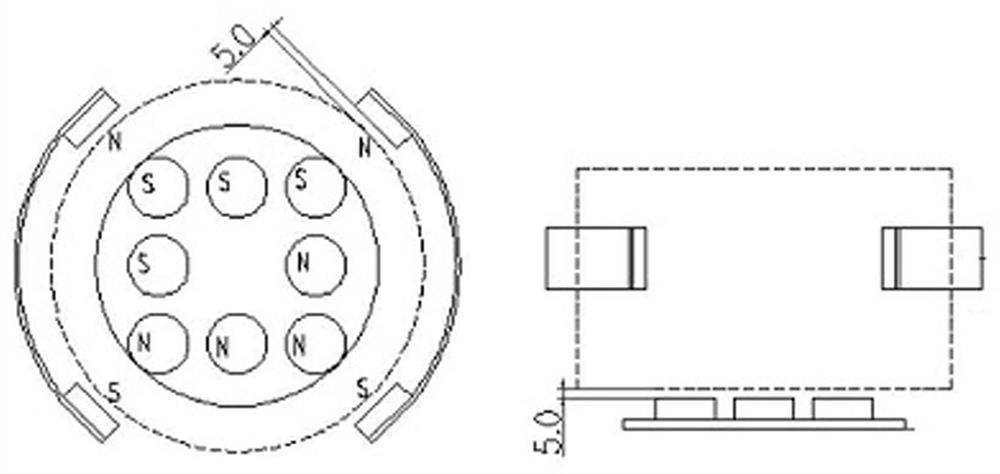

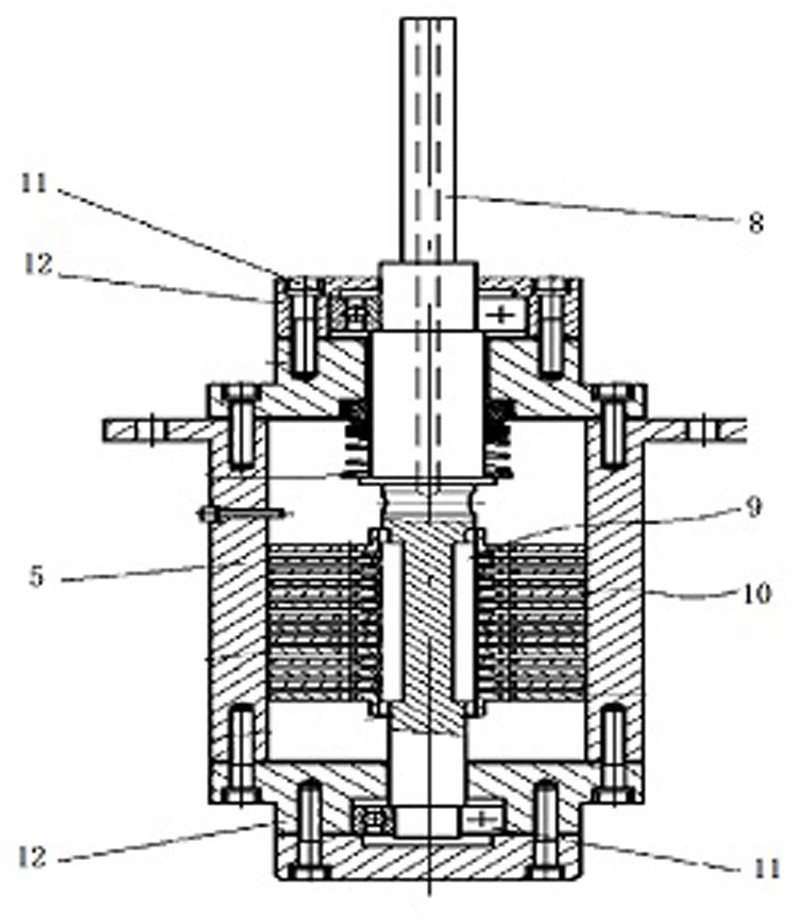

A technology of polishing device and rotating cylinder, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., which can solve problems such as low efficiency, affecting polishing effect and efficiency, and inability to form a closed magnetic force line loop. To achieve the effect of increasing the distribution density of magnetic lines of force and the intensity of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An ultra-high-speed polishing of workpiece surfaces.

[0042] 1. Clean the workpiece with an ultrasonic cleaner for 5-10 minutes, and then dry it with a hair dryer;

[0043] 2. Proportionate water, abrasive liquid, abrasive material, and magnetic needle; that is, 1500ml of water, 300g of magnetic needle with a diameter of 0.5mm, 25ml of abrasive liquid, and 150g of magnetic abrasive are put into container 1 together with the workpiece;

[0044] 3. Connect the high-pressure gas compressor to the Tesla turbine 4, connect to the power supply, and turn on the start switch;

[0045] 4. According to the amount of the workpiece, time 2-5 minutes to perform ultra-high-speed polishing on the surface of the workpiece;

[0046] 5. After the processing is completed, press the stop button, take out the container and separate the workpiece and the magnetic needle;

[0047] 6. Clean the workpiece with an ultrasonic cleaner for 5-10 minutes, and then dry it with a hair dryer.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com