Disc type gas-liquid two-phase fluid uniform distribution device

A disc-type, gas-liquid technology, used in lighting and heating equipment, heat exchange equipment, heat exchanger shells, etc. problem, to achieve the effect of ensuring balanced connectivity, good uniform distribution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

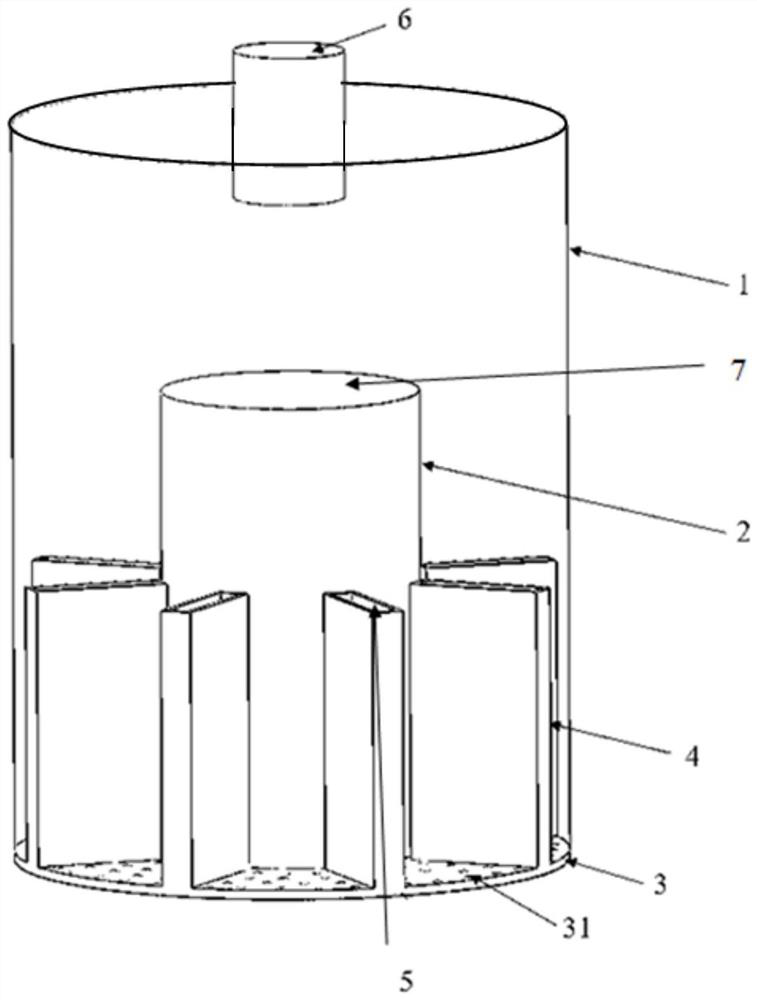

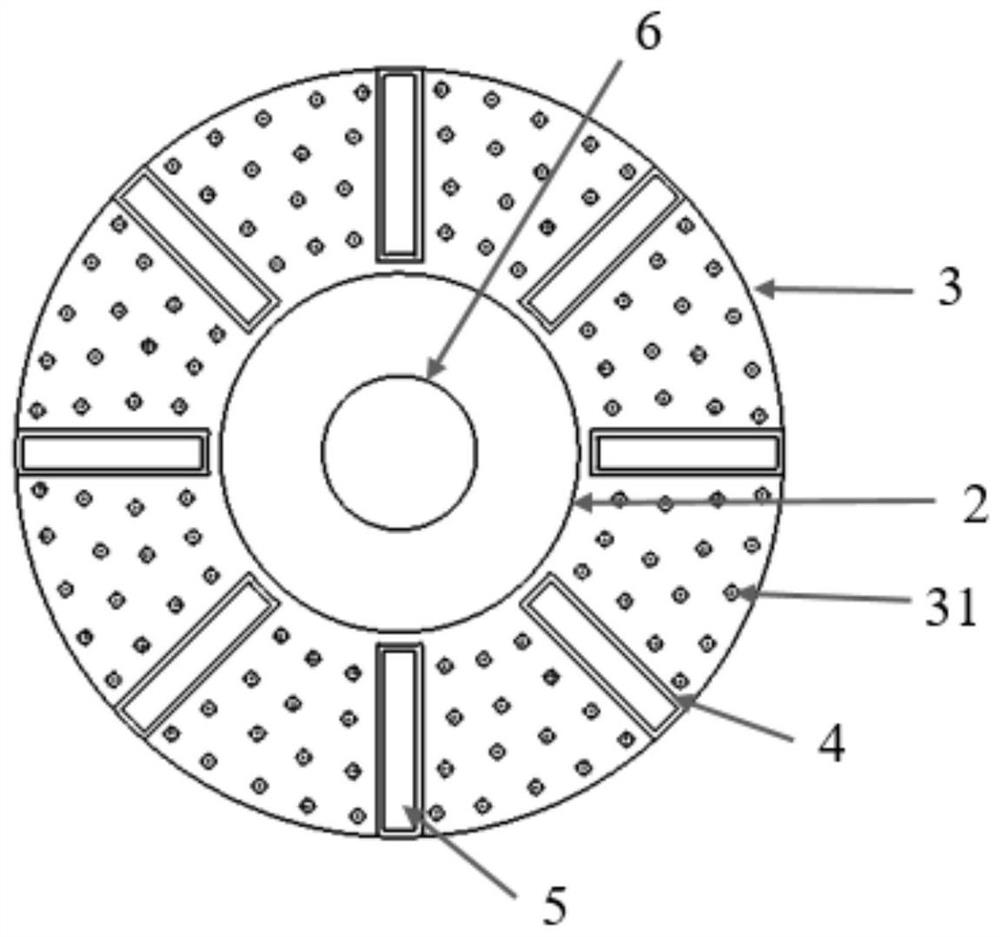

[0023] Such as Figure 1-Figure 2 As shown, a disc-type gas-liquid two-phase fluid uniform distribution device includes a vertically arranged shell cylinder 1, and a central cylinder 2 is arranged inside the shell cylinder 1, and the central cylinder The upper end of 2 is sealed by a baffle 7, and the lower outer wall of the central cylinder 2 is provided with a ring plate 3 tightly connected with the inner wall of the shell cylinder 1, and the ring plate 3 is uniformly provided with A plurality of flow equalization holes 31 are used to allow the liquid phase fluid to flow out uniformly; a number of stoppers 4 are evenly arranged between the outer shell cylinder 1 and the central cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com