Mining automatic explosion-proof water curtain device with dust lowering function

A water curtain and functional technology, applied in safety devices, dust prevention, mining equipment and other directions, can solve the problems of few sprinklers, hidden safety hazards, poor dust reduction effect, etc., to reduce workload and cost, isolate the spread of explosive flames, reduce The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

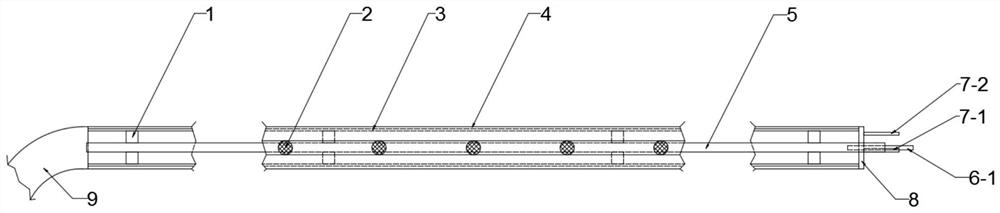

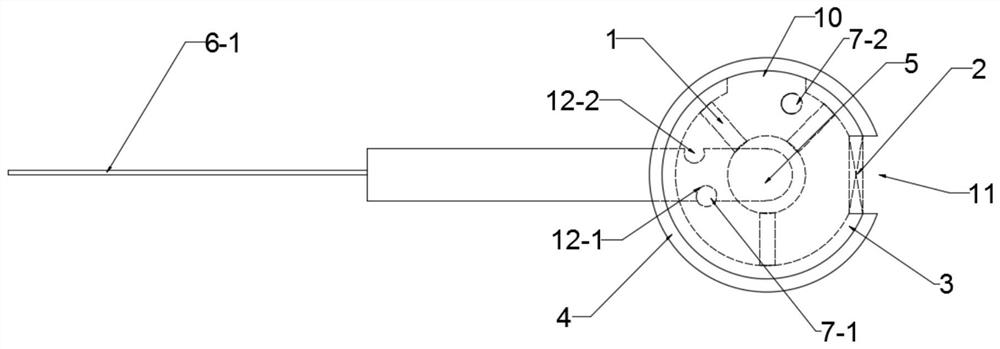

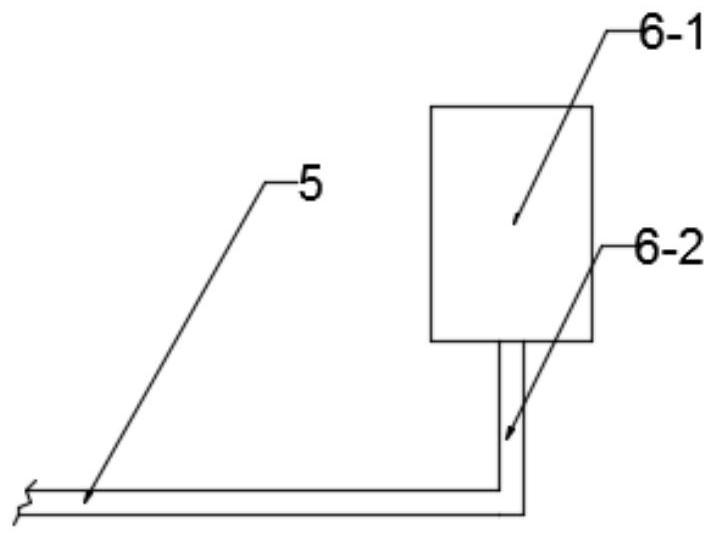

[0030] A mining automatic explosion-proof water curtain device with dust suppression function, its structure diagram is as follows figure 1 As shown, the cross-sectional diagram is shown in figure 2 As shown, it includes a rotating shaft 5, an inner tube 3 and an outer tube 4 arranged sequentially from the inside to the outside, wherein:

[0031] The rotating shaft 5 and the inner tube 3 are welded and connected by the welding piece 1, the outer tube 4 is sleeved outside the inner tube 3, and the inner tube 3 is a rotatable inner tube 3;

[0032] The surface of the inner pipe 3 is provided with an atomizing nozzle 2 and a water curtain opening 10 , wherein the atomizing nozzle 2 is arranged on the side wall of the inner pipe 3 , and the water curtain opening 10 is arranged on the upper part of the inner pipe 3 .

[0033] The outer pipe 4 includes a liquid outlet 11, a waterproof sealing cover 8 and a pressure water supply pipe 9, wherein the liquid outlet 11 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com