Inspection well for pipeline engineering and cover structure

A pipeline engineering and cover structure technology, which is applied in water conservancy projects, underwater structures, infrastructure engineering, etc., can solve problems such as failure to open inspection well covers, vehicle driving accidents, and inspection well covers being stolen, so as to reduce maintenance costs and maintenance costs. The number of times, the effect of ensuring the smoothness of the road surface and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] See attached figure 1 , 2 , shown in 5, the inspection well that is used for plumbing works, comprises: inspection well, and the well wall of the inspection well is fitted with the inspection well support assembly 40, and the inspection well support assembly 40 includes a support box body 48, and the support box body 48 top is penetrated and set, and supports The box body 48 is provided with a second assembly cover plate 45 that can move up and down, and at least three support springs 46 are provided below the second support cover plate 45. An assembly cover 41 is closed, and the space between the first assembly cover 41 and the second assembly cover 45 is filled with the second filler 43, the first filler 42 and the third filler 44, and the second filler 43 is arranged on both sides The first filling piece 42, the third filling piece 44, the relative distance between the two sides of the second filling piece 43 and the first filling piece 42, the third filling piece 4...

Embodiment 2

[0034] Present embodiment is optimized as follows on the basis of embodiment 1: see appendix Image 6 As shown, a support slot 411 is vertically provided on the opposite surface of the support box body 48 box surface attached to the well wall of the inspection well. Preferably, a support steel bar 410 is placed in the support slot 411 . Each supporting box body 48 is inserted end to end to form the ring body that is easy to break when bearing excessive load respectively, by presetting the mode of supporting slot 411 on the box surface of supporting box body 48 to make it bear the excessive load along preset. Deformation occurs in the direction to reduce the deformation of the annulus formed by the supporting box body 48 so that it fits the wall of the inspection well as far as possible. In order to resist excessive deformation, a supporting steel bar 410 is set in the supporting slot 411.

Embodiment 3

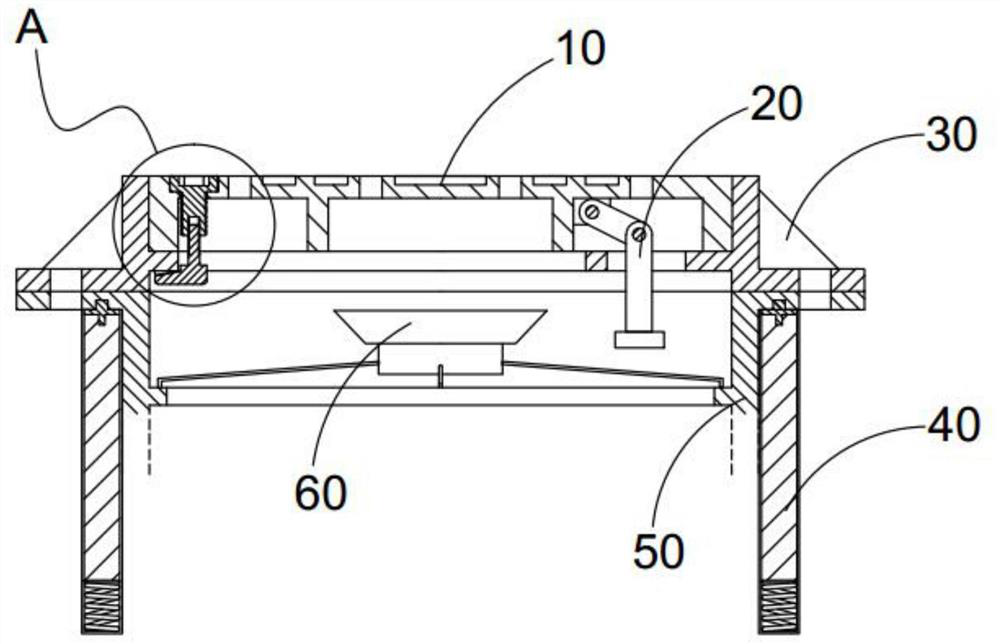

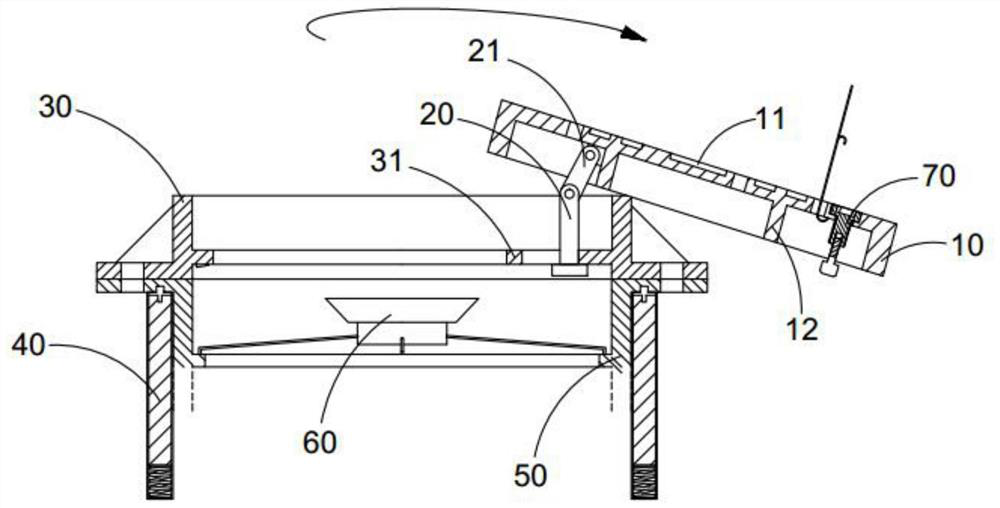

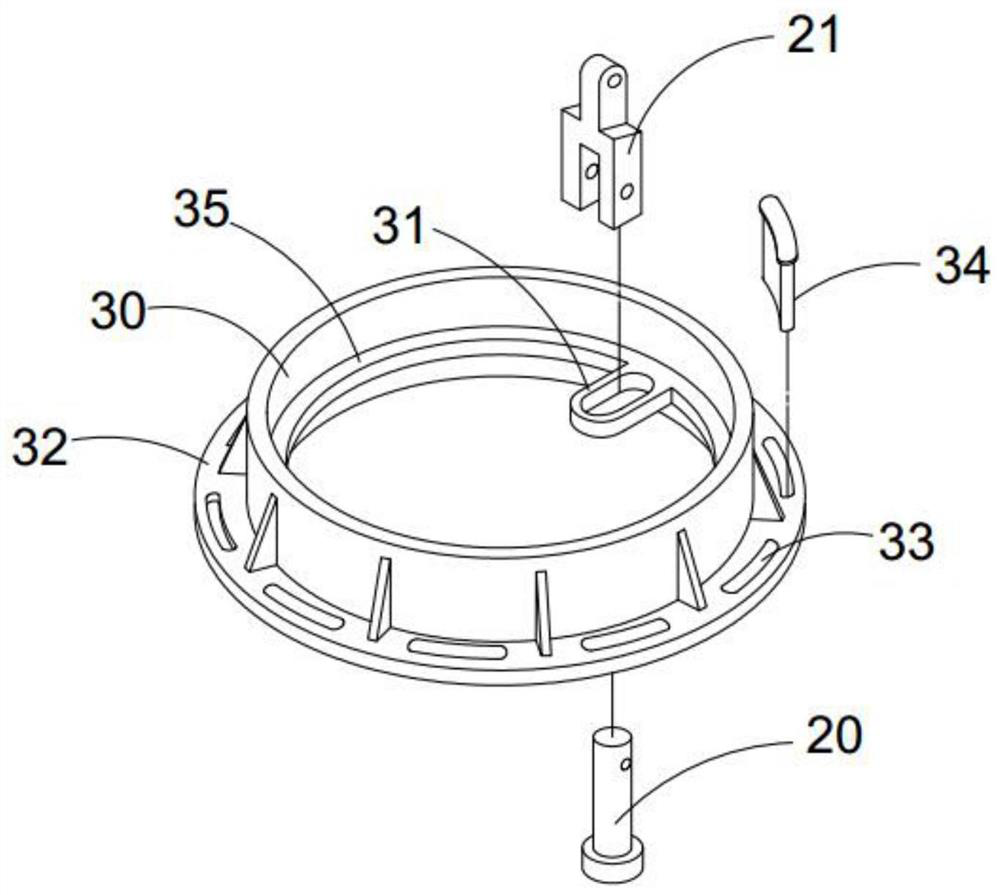

[0036] See attached Figure 1-7 As shown, the technical solution adopted by the present invention to achieve the above object is: the cover structure used for pipeline engineering inspection wells, including:

[0037] The inspection shaft support assembly 40, the inner wall of the inspection shaft support assembly 40 is fitted with an auxiliary support pipe 50, the upper port of the auxiliary support pipe 50 has an extension ring body, the extension ring body is provided with a well cover seat 30, and the inspection shaft cover 10 is installed on the well cover seat 30,

[0038]Wherein, the manhole support assembly 40 includes a support box body 48, and the upper part of the support box body 48 is set through. The support box body 48 is provided with a second assembly cover plate 45 that can move up and down. The support spring 46, the upper opening of the supporting box body 48 is covered by the first assembly cover 41 matching the shape of the opening, and the second filler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com