Wool trimming and cleaning device

A cleaning device and wool technology, applied in liquid/gas/vapor treatment transmission, textile and papermaking, fiber treatment, etc., can solve the problems of low work efficiency and uneven wool, and achieve the effect of good placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

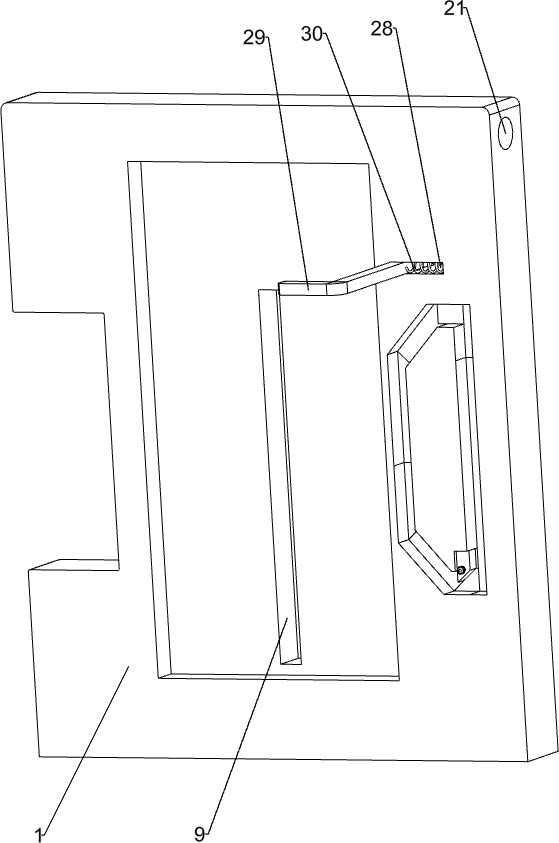

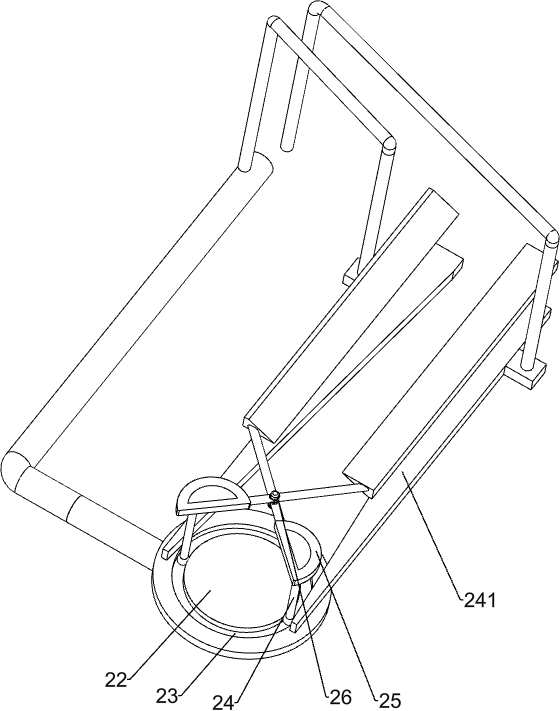

[0021] A wool trimming and cleaning device, such as Figure 1-5 As shown, it includes a base 1, a rotating assembly, a lifting cleaning assembly and a trimming assembly. The base 1 is used to install the entire device. The upper right side of the rotating assembly is provided with a rotating assembly that provides power. The cleaning assembly is lifted and lowered, and the left side of the top of the base 1 is provided with a trimming assembly that trims by swinging.

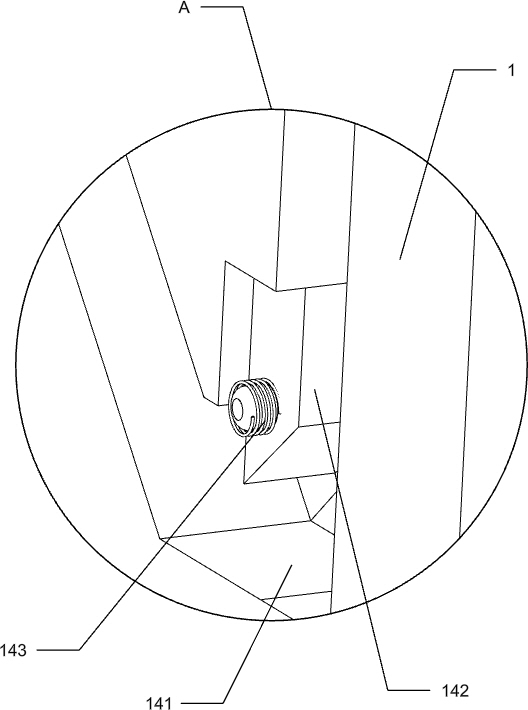

[0022] Such as figure 1 and 2 As shown, the rotating assembly includes a reduction motor 2, a first rotating rod 3, a first gear 4, a circular sliding sleeve 6, a first spring 7, a circular block 8, a second rotating rod 10, a second gear 11 and a first A gear rack 12, the right side of the upper part of the base 1 is fixedly connected with a geared motor 2 by bolts, the output shaft of the geared motor 2 is provided with a first rotating rod 3, the front end of the first rotating rod 3 is provided with a firs...

Embodiment 2

[0030] On the basis of above-mentioned embodiment 1, as figure 1 As shown, a placement plate 27 is also included, and a placement plate 27 is welded between the top and front sides of the mounting rods 15, and the placement plate 27 cooperates with the first clamping block 16 and the second clamping block 19 .

[0031] On the basis of above-mentioned embodiment 1, as figure 1 , 2 Shown in and 4, also include bar 29 and the 3rd spring 30, base 1 top right side has second through hole 28, is provided with bar 29 slidingly in the second through hole 28, bar 29 and base 1 A third spring 30 is connected between them.

[0032] The specific operation process of the above-mentioned embodiment: when the wool is placed, one end of the wool is always in contact with the placing plate 27, so that the wool can be placed more evenly without the manual arrangement of the staff.

[0033] When the second clamping block 19 is moved backward, push the clamping lever 29 to slide to the right, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com