Low titanium slag dry method treating device and dry method treating process

A technology of dry treatment and titanium slag, applied in the direction of improving process efficiency, etc., can solve the problems of high cost of low titanium slag treatment, difficult treatment of high-salt wastewater, huge environmental protection pressure of enterprises, etc., to reduce treatment costs and reduce environmental pressure , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

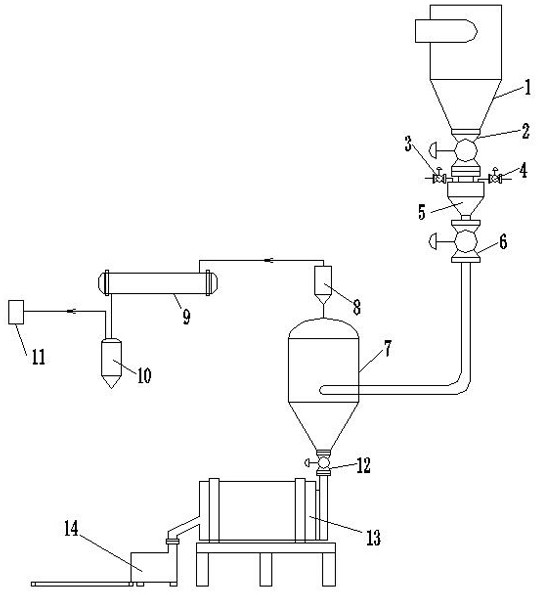

[0018] Referring to the accompanying drawings, a low-titanium slag dry processing device includes a cyclone dust collector 1. During the production of titanium tetrachloride, high-temperature titanium tetrachloride gas enters the cyclone dust collector 1 for gas-solid separation to obtain low-titanium slag The ash outlet of the cyclone dust collector 1 is provided with a set of ash storage hopper 5 specially used for temporary storage of ash and avoiding the secondary hoisting of dust, and the upper ash valve 2 and the outlet of the ash storage hopper 5 are provided with a lower ash valve 6, The amount of ash storage is controlled by the upper ash valve 2 and the lower ash valve 6; the ash storage hopper 5 is provided with a nitrogen pressure pipe and a pressure relief pipeline to ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com