Large-scale production method for clostridium butyricum

Clostridium butyricum, a production method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of many butyric acid passage times, long production cycle, large demand for butyric acid seed solution, etc. , to achieve the effects of reducing the risk of strain variation, reducing the passage of strains, and shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

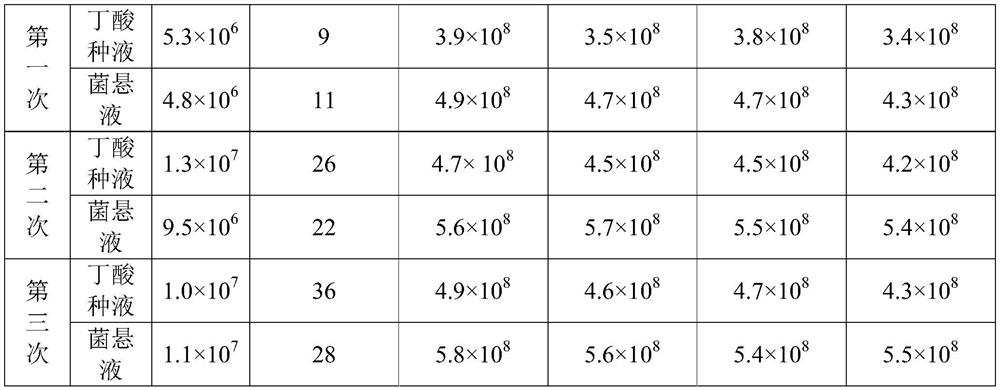

[0052] According to the method of above comparative example and embodiment, the total number of live bacteria contained in the bacterium suspension of embodiment is adjusted to 3.5L Clostridium butyricum bacteria liquid (butyric acid seed solution) in the comparative example is the same Order of magnitude, measure the number of 0h viable bacteria inoculated into the seed tank and the bacteria content in the Clostridium butyricum fermenter, the results are shown in Table 1-Table 3.

[0053] Table 1 Comparison of fermentation effects when the number of live bacteria in 0h is 9-28CFU / ml

[0054]

[0055]

[0056] Table 2 The number of live bacteria in 0h is 10 2 Comparison of fermentation effects at CFU / ml level

[0057]

[0058] Table 3 0h live bacteria count is 10 3 Comparison of fermentation effects at CFU / ml level

[0059]

[0060]

[0061] From the above data, it can be seen that when the number of viable bacteria at 0h is basically the same, the 3.5L Clost...

experiment example 2

[0063] Select the total number of viable bacteria as the total number of viable bacteria in the bacterial suspension to be 10 5 、10 6 、10 7 、10 8 、10 9 、10 10 The Clostridium butyricum suspension of CFU was respectively put into 500L first-class seed tanks of Clostridium butyricum. Under the same conditions of other processes, the fermentation effects are shown in Table 4 and Table 5.

[0064] Table 4 total number of different live bacteria (10 5 、10 9 、10 10 CFU) Clostridium butyricum suspension fermentation effect

[0065]

[0066] Table 5 total number of different live bacteria (10 6 、10 7 、10 8 CFU) Clostridium butyricum suspension fermentation effect

[0067]

[0068] Can know by above-mentioned experiment: in clostridium butyricum seed tank 0h live bacteria number is in 10 2 ~10 4 CFU / ml (the fourth group-the sixth group), that is, the total number of live bacteria of Clostridium butyricum inserted is at 10 6 ~10 9 CFU, the time required for Clostrid...

experiment example 3

[0073] In the manner of the reference example, the Clostridium butyricum suspension was inoculated into 50L, 500L, and 1000L seed tanks respectively for anaerobic culture, and then the fermented strains obtained in the seed tank were inoculated into the Clostridium butyricum fermentation Fermentation culture was carried out in the tank, and the results are shown in Table 6.

[0074] The fermentation effect of the method of the embodiment of table 6 in different volume seed tanks

[0075]

[0076] From the experimental results in Table 6, it can be seen that by adjusting the total number of viable bacteria at the time of access, the number of viable bacteria at 0h is guaranteed to reach 10 2 -10 4 CFU / ml, the number of live bacteria can be obtained by large-scale fermentation at 10 8 Clostridium butyricum products above CFU / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com