High-boiling-point all-organic cooling liquid and preparation method thereof

A high boiling point, cooling liquid technology, applied in the field of cooling liquid, can solve the problem of low boiling point of cooling liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

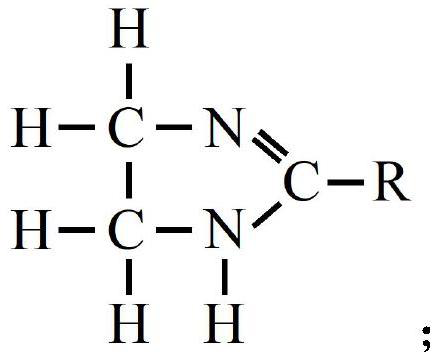

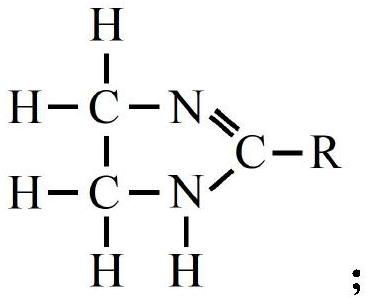

Image

Examples

Embodiment 1

[0051]Step 1, get palladium acetate 22.45g (0.1mol), add in the reactor that is equipped with pressure detector, temperature detector, stirring device, cooling pipe and by-product receiving tank, add valeric acid 102g (1mol), in reactor Stir evenly, heat up to 60°C, vacuum 60mmHg, keep warm for 2.5 hours, distill off the acetic acid generated by the reaction, cool to room temperature to obtain 112.45g of palladium valerate-valeric acid homogeneous catalyst solution, containing 31.042g of palladium valerate (0.1mol palladium meter);

[0052] Step 2, 60.1g (1mol) of ethylenediamine and 90.12g (1mol) of ethylene glycol monoethyl ether are mixed in the reactor, stirred evenly in the reactor (from which the products of step 1 have been taken out), and 1g of palladium valerate is added ~ valeric acid homogeneous catalyst solution, feed air, stir evenly, control the temperature at 90°C, vacuum 100mmHg, react for 2.5 hours, steam the water generated by the reaction to obtain 128g (1mo...

Embodiment 2

[0055] Step 1, get palladium acetate 44.9g (0.2mol), add in the reactor that is equipped with pressure detector, temperature detector, stirring device, cooling pipe and by-product receiving tank, add valeric acid 102g (1mol), in reactor Stir evenly, heat up to 100°C, vacuum 10mmHg, keep warm for 2 hours, distill off the acetic acid generated by the reaction, cool to room temperature to obtain 122.9g of palladium valerate-valeric acid homogeneous catalyst solution, containing 62.084g of palladium valerate (0.2mol palladium meter);

[0056] Step 2, 60.1g (1mol) of ethylenediamine and 180.24g (2mol) of ethylene glycol monoethyl ether are mixed in the reactor, stirred evenly in the reactor (from which the products of step 1 have been taken out), and 0.1g of valeric acid is added Palladium~valeric acid homogeneous catalyst solution, pass into air, stir evenly, control temperature at 100 ℃, vacuumize 10mmHg, react for 2 hours, steam the water that reacts to generate, obtain 2-alkoxy...

Embodiment 3

[0059] Step 1, get palladium acetate 67.35g (0.3mol), add in the reactor that is equipped with pressure detector, temperature detector, stirring device, cooling pipe and by-product receiving tank, add valeric acid 102g (1mol), in reactor Stir evenly, heat up to 80°C, vacuum 120mmHg, keep warm for 3 hours, distill off the acetic acid generated by the reaction, cool to room temperature to obtain 133.35g of palladium valerate-valeric acid homogeneous catalyst solution, containing 93.13g of palladium valerate (0.3mol palladium meter);

[0060] Step 2, 60.1g (1mol) of ethylenediamine and 270.36g (3mol) of ethylene glycol monoethyl ether are mixed in the reactor, stirred evenly in the reactor (from which the products of step 1 have been taken out), and 10g of palladium valerate is added ~ valeric acid homogeneous catalyst solution, feed into air, stir evenly, control temperature at 95 ℃, vacuumize 55mmHg, react for 3 hours, steam the water that reaction generates, obtain 2-alkoxyl i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com