Active flow distribution type electromagnetic direct-drive hydrostatic brake unit and control method thereof

A technology of braking unit and control method, applied in the directions of brakes, braking transmissions, transportation and packaging, etc., can solve the problems of complex hydraulic pipelines and high energy consumption, and achieve high power transmission efficiency, huge economic benefits, and dynamic response. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further detailed below with reference to the accompanying drawings and specific embodiments.

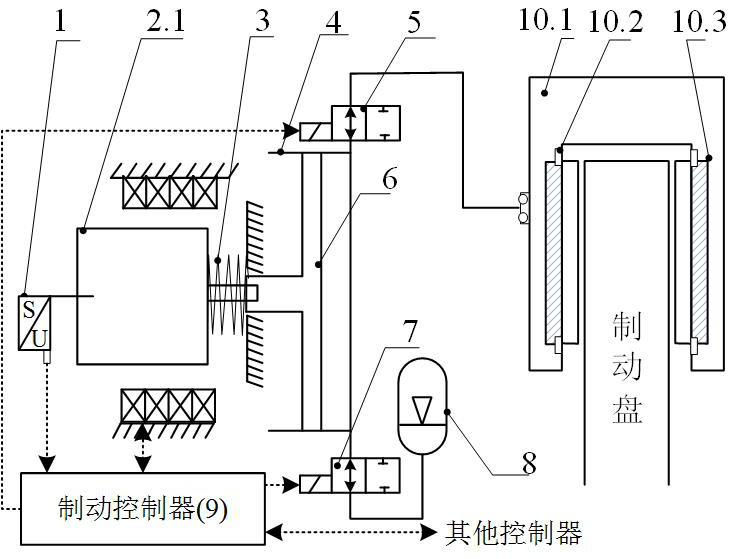

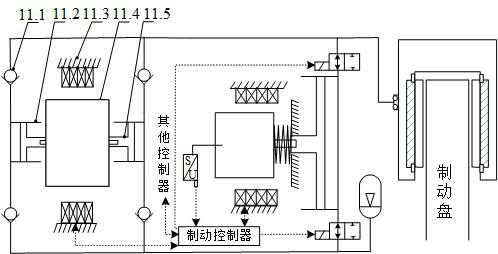

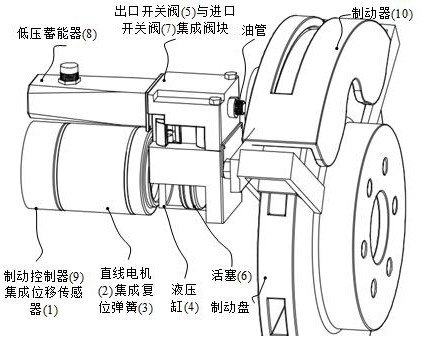

[0020] like figure 1 An active flow shown with electromagnetic direct drive hydrostatic braking unit and a control method comprising a displacement sensor (1), the linear motor (2), a return spring (3), the cylinder (4), the outlet switching valve (5 ), a piston (6), the switching valve inlet (7), low-pressure accumulator (8), brake controller (9), the brake (10), characterized by comprising: a linear motor mover (2.1) direct drive piston ( 6) in the cylinder (reciprocates outlet shutoff valve (5) 4), the inlet switching valve (7) is a normally open valve and are mounted between the cylinder (4) and the brake working chamber (10), a hydraulic cylinder (4) low-pressure accumulator and the working chamber (8); when the linear motor (2) does not operate, under action of the return spring (3) thrust piston (6) located at the end of the liquid suction stroke; b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com