Multi-station milling numerical control machine tool

A technology of milling processing and CNC machine tools, which is applied in the field of machine tools, can solve problems such as inability to deal with machine tool waste, achieve automatic crushing, improve processing efficiency and processing effects, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

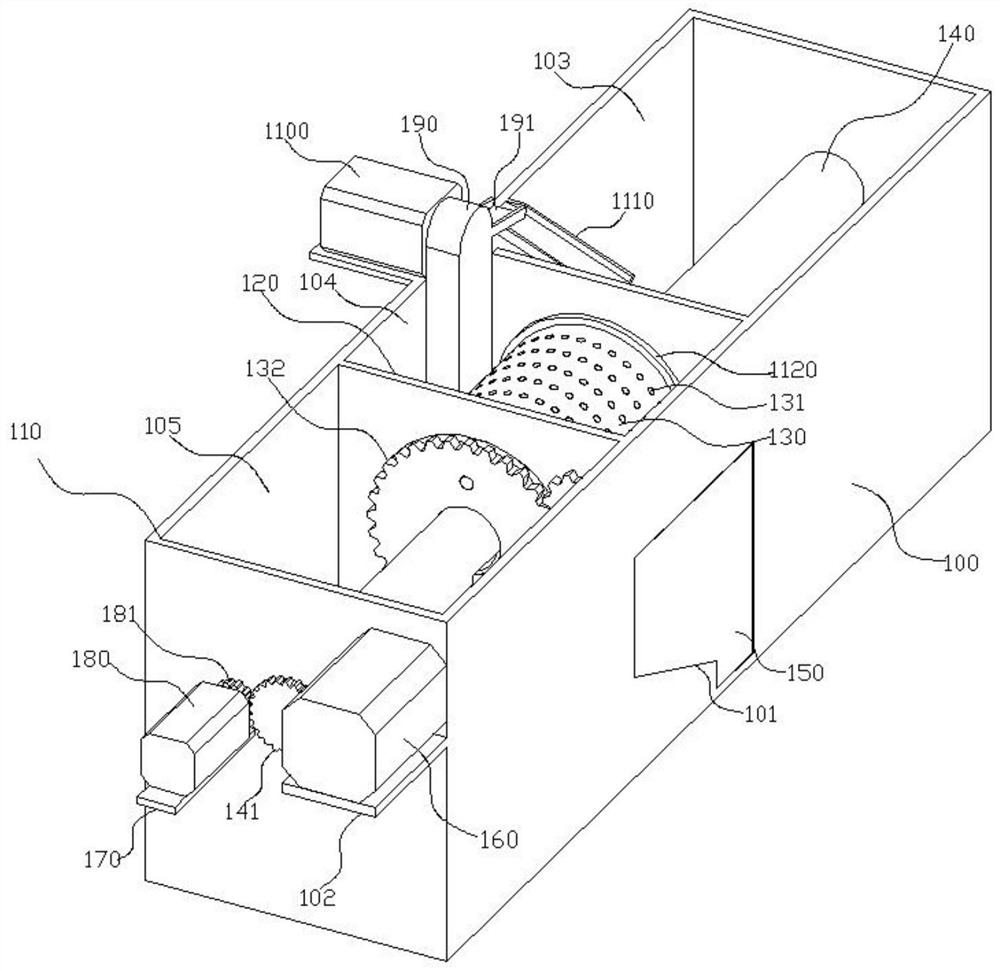

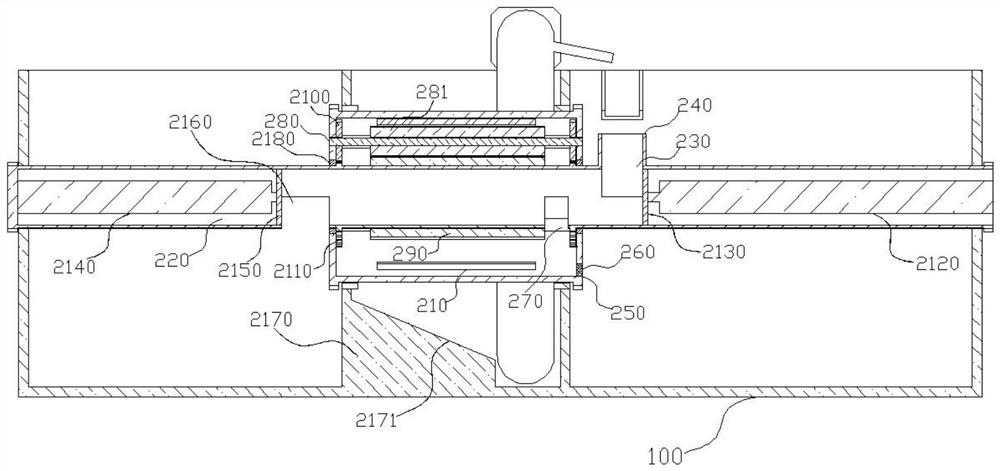

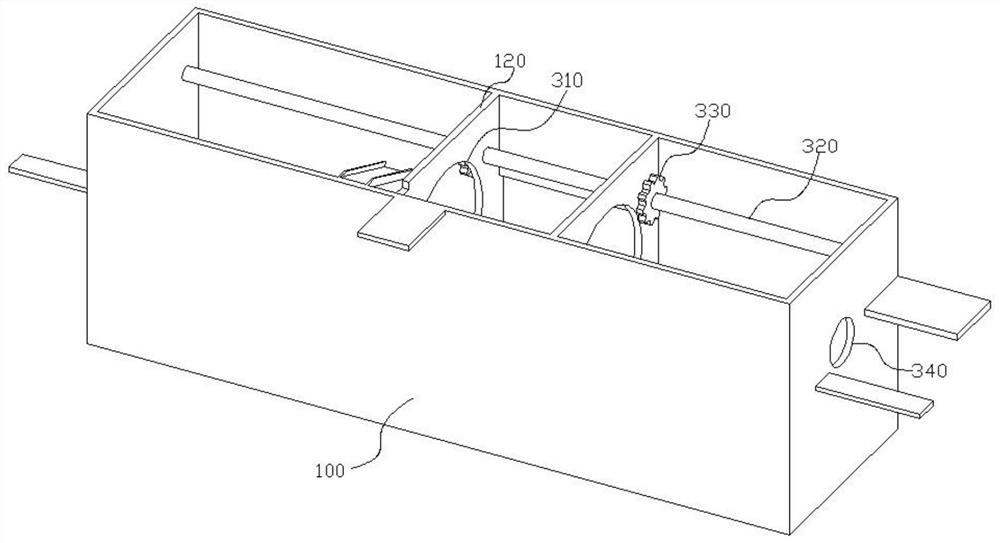

[0046] Such as Figure 1-14 As shown, the present embodiment provides a multi-station milling CNC machine tool, which includes a machine tool body 1410, a milling mechanism 1420 is provided on the upper end of the machine tool body 1410, a workbench 1430 is provided in the machine tool body 1410, and the workbench 1430 The upper end surface of the workbench is provided with a clamping mechanism 1440 for fixing the workpiece, the workbench 1430 is provided with a workbench through hole 1450, and the bottom of the workbench 1430 is provided with a waste collection device 1460; the clamping mechanism 1440 includes a fixture mounting seat 610 , the upper end surface of the fixture mounting seat 610 is provided with four first slide grooves 620, and the four first slide grooves 620 all extend from the edge of the fixture mounting seat 610 to the center of the fixture mounting seat 610, and the two adjacent The first chute 620 is perpendicular to each other, the first chute 620 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com