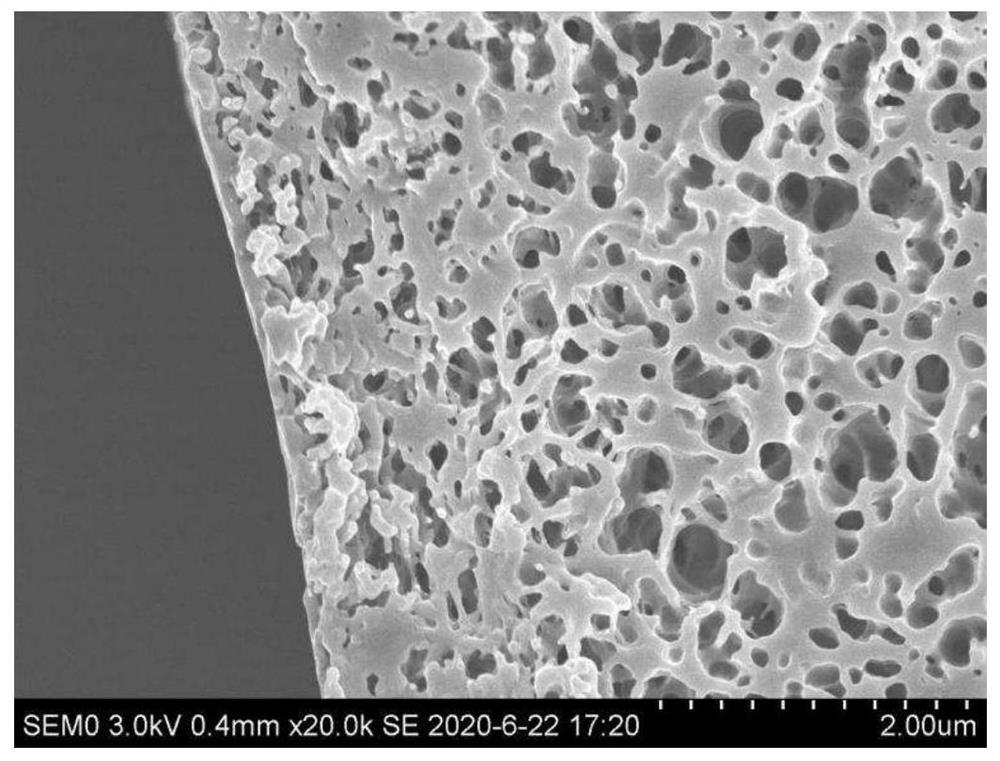

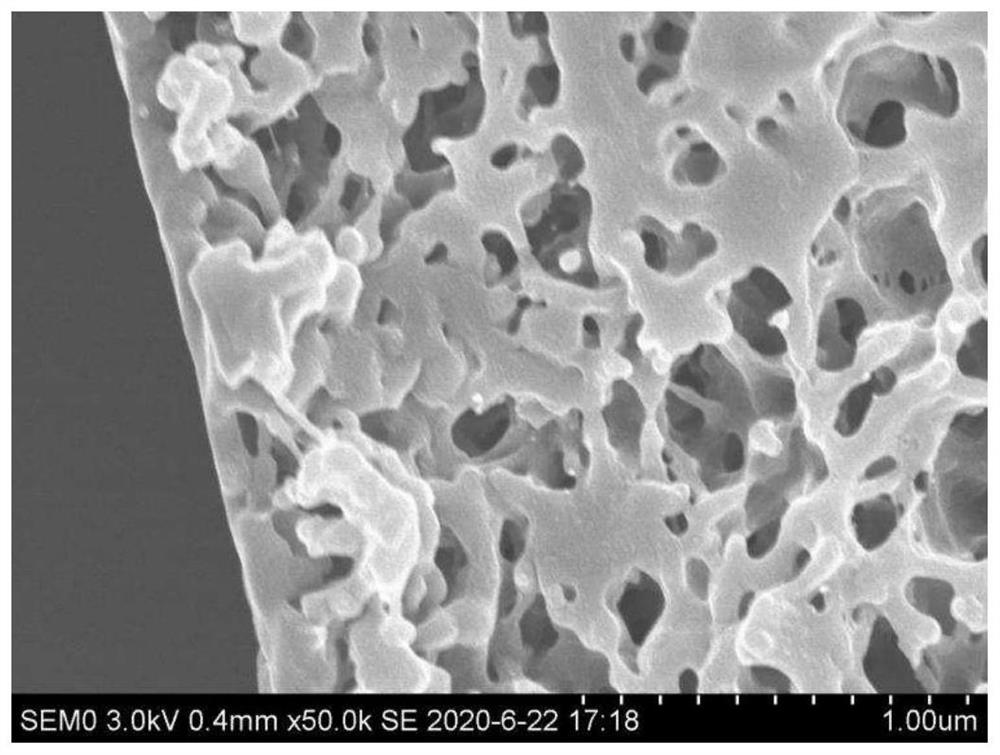

Asymmetric hydrophobic polyolefin hollow fiber membrane, preparation method and application thereof

A fiber membrane and hydrophobic technology, applied in the field of membrane materials, can solve the problems of the entry of anesthetic gas hollow fiber membrane, increase the cost of surgery, secondary damage to the physical and mental health of patients, etc., and achieve the effect of high penetration rate and ensuring physical and mental health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A method for preparing an asymmetric hydrophobic polyhydrocarbon hollow fiber membrane, comprising the following steps:

[0067] Step 1: put 40wt% polypropylene into a twin-screw extruder, heat until plasticized, and then add a solvent system consisting of 45wt% methyl-12-hydroxystearic acid and 15wt% dioctyl adipate, Form a mixture, stir and knead at 230°C to obtain a homogeneous casting solution;

[0068] Step 2: extruding the casting solution from a die with a temperature of 215°C to obtain a molded product with an inner surface and an outer surface;

[0069] Step 3: Place the molded product in the air section for preliminary phase separation, the residence time is 10ms; the temperature of the air section is 100°C, and the relative humidity is 30%;

[0070] Step 4: Use methyl-12-hydroxystearic acid as the cooling liquid to cool the molded product, the cooling temperature is 40°C, and the cooling residence time is 55ms;

[0071] Step 5: Then use methyl-12-hydroxyste...

Embodiment 2

[0074] A method for preparing an asymmetric hydrophobic polyhydrocarbon hollow fiber membrane, comprising the following steps:

[0075] Step 1: Put 31wt% polypropylene into a twin-screw extruder, heat until plasticized, then add a solvent system consisting of 46wt% dibutyl sebacate and 23wt% castor oil to form a mixture, and heat it at 255°C Stir and knead to obtain a homogeneous casting solution;

[0076] Step 2: extruding the casting solution from a die with a temperature of 230°C to obtain a molded product with an inner surface and an outer surface;

[0077] Step 3: Place the molded product in the air section for preliminary phase separation, the residence time is 5ms; the temperature of the air section is 105°C, and the relative humidity is 25%;

[0078] Step 4: Use the solvent system (solvent system composed of 46wt% dibutyl sebacate and 23wt% castor oil) used when preparing the casting solution as the cooling liquid to cool the molded product, the cooling temperature is...

Embodiment 3

[0083] A method for preparing an asymmetric hydrophobic polyhydrocarbon hollow fiber membrane, comprising the following steps:

[0084] Step 1: put 48wt% polypropylene into a twin-screw extruder, heat until plasticized, then add a solvent system consisting of 39wt% dibutyl phthalate and 13wt% dioctyl adipate to form a mixture , stirring and kneading at 245°C to obtain a homogeneous casting solution;

[0085] Step 2: extruding the casting solution from a die with a temperature of 220°C to obtain a molded product with an inner surface and an outer surface;

[0086] Step 3: Place the molded product in the air section for preliminary phase separation, the residence time is 15ms; the temperature of the air section is 80°C, and the relative humidity is 35%;

[0087] Step 4: Use dibutyl phthalate as the cooling liquid to cool the molded product, the cooling temperature is 30°C, and the cooling residence time is 60ms;

[0088] Step 5: Then use dibutyl phthalate as the quenching liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com