All-solid-state battery cell, preparation method thereof and solid-state battery

An all-solid-state, cell technology, applied in non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of difficult to achieve the leap of all-solid-state batteries, inability to realize the application of ultra-thin sulfide electrolyte membranes, etc. The strength requirements and types of restrictions are small, the effect of promoting the progress of research and development, and reducing the amount of electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

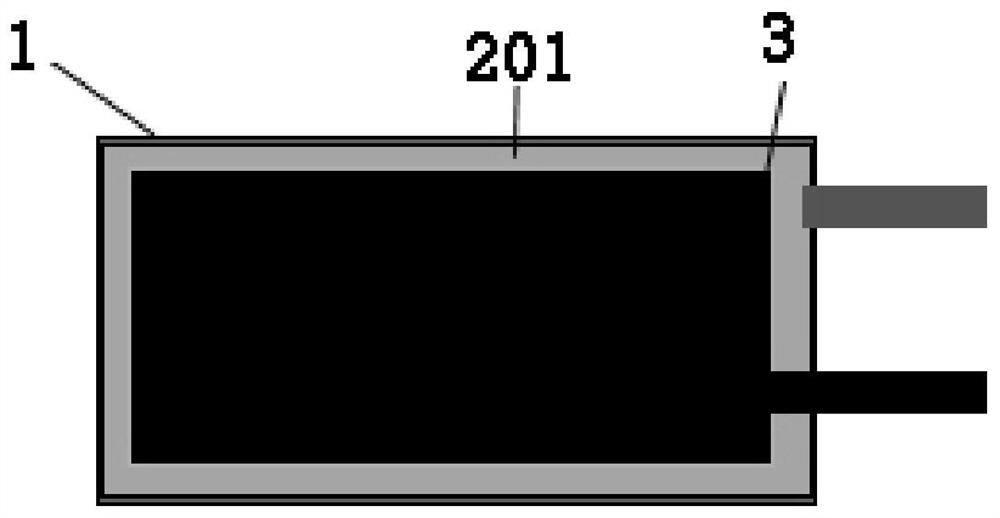

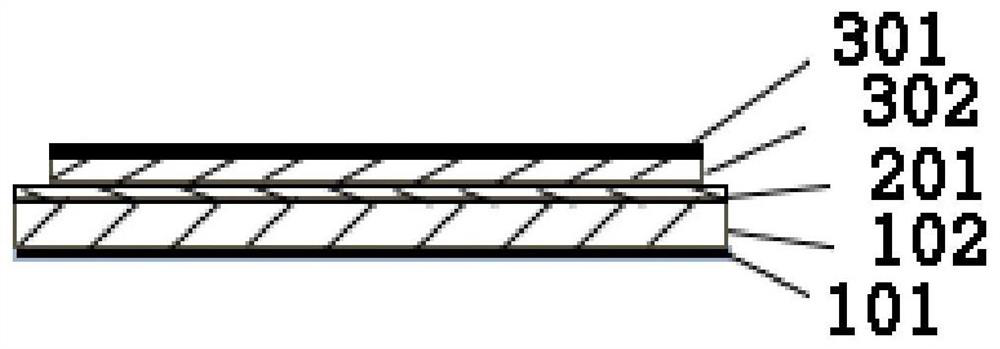

Image

Examples

Embodiment 1

[0091] In this embodiment, an all-solid-state battery cell is prepared according to the following method:

[0092] (1) An electrolyte membrane (Li 10 GeP 2 S 12 (LGPS) electrolyte membrane) is pasted on the negative electrode sheet (single-sided negative electrode sheet, the negative electrode current collector is copper foil, the negative electrode active material layer is composed of negative electrode active material, sulfide electrolyte, conductive agent and binder, and the negative electrode active material is silicon. , the sulfide electrolyte is LGPS, the conductive agent is carbon nanotube CNT, the binder is SBR, and the mass ratio of negative electrode active material, conductive agent and binder is 10:80:5:5), at 100°C Under the pressure of 500MPa, carry out warm isostatic pressing treatment, the number of times of pressing is 5 times, and the holding time of each time is 100min, after which the matrix is removed to obtain the first semi-finished battery cell;

...

Embodiment 2

[0099] In this embodiment, an all-solid-state battery cell is prepared according to the following method:

[0100] (1) Lay the electrolyte membrane (thickness and material identical to the electrolyte membrane of Example 1) on the substrate (polytetrafluoroethylene substrate) to the negative electrode sheet (double-sided negative electrode sheet, the negative electrode current collector is copper foil, each The type and ratio of the components of the negative active material layer on one side are the same as the negative active material of Example 1) on both sides, carry out isostatic pressing according to the same conditions as in Example 1 step (1), and then remove the Substrate to obtain the first semi-finished battery cell;

[0101] (2) On the electrolyte membranes on both sides of the first semi-finished electric core described in step (1), affix the positive electrode sheet (the positive electrode current collector is an aluminum foil, and the component type and ratio of...

Embodiment 3

[0106] In this embodiment, an all-solid-state battery cell is prepared according to the following method:

[0107] (1) An electrolyte membrane (Li 6 P.S. 5 Cl (LPSCl) electrolyte membrane) is pasted on the negative electrode sheet (single-sided negative electrode sheet, the negative electrode current collector is copper foil, the negative electrode active material layer is composed of negative electrode active material, sulfide electrolyte, conductive agent and binder, and the negative electrode active material is Graphite, the sulfide electrolyte is LPSCl, the conductive agent is conductive carbon black SP, the binder is SBR, and the mass ratio of negative electrode active material, conductive agent and binder is 55:40:5:5), on one side at 25 cold isostatic pressing at a pressure of 500 MPa at ℃, the number of times of pressing is 5 times, and the holding time of each time is 300 minutes, and then the matrix is removed to obtain the first semi-finished battery cell;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com