Liquid cooling heat dissipation device and heat dissipation system

A liquid-cooled heat dissipation and heat dissipation cold plate technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of single and ineffective heat dissipation methods, high-efficiency heat dissipation, and low heat dissipation efficiency of heat dissipation structures, so as to improve heat dissipation efficiency and improve The degree of heat dissipation and the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

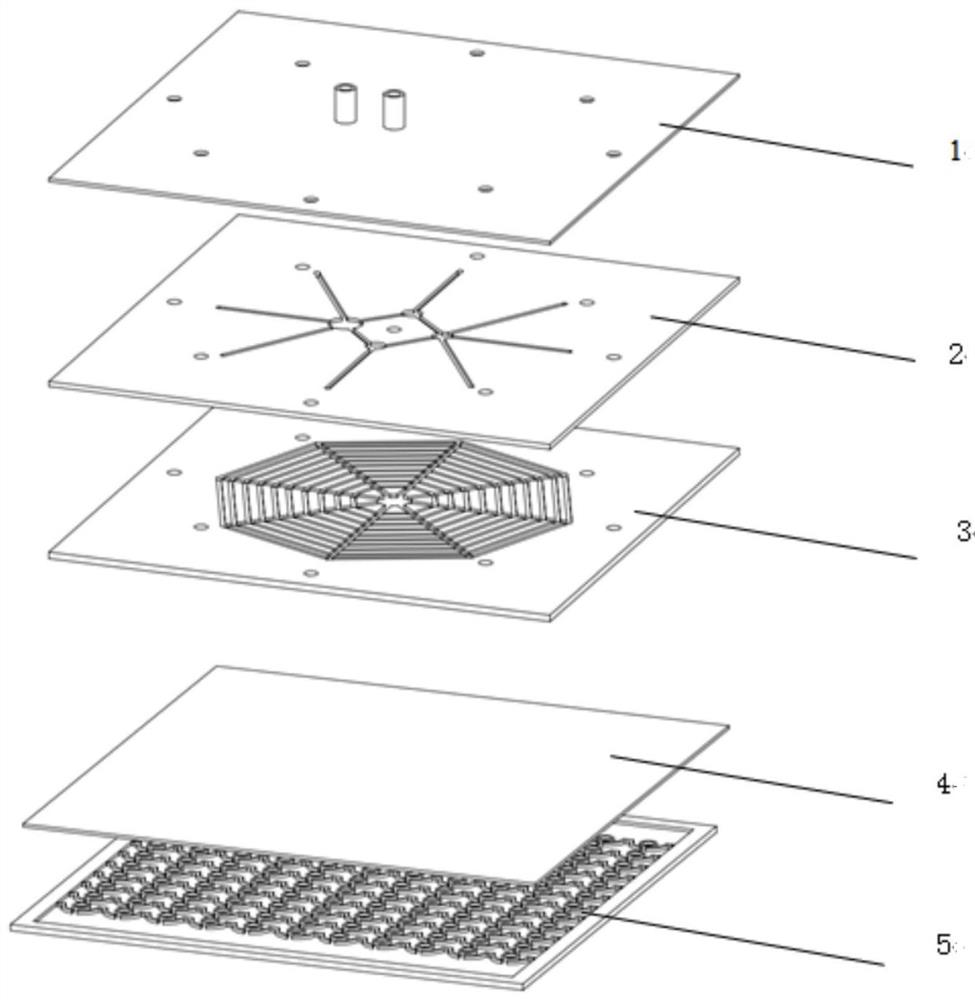

[0043] A liquid cooling device, such as figure 1 As shown, it includes a paraffin liquid cooling device and a microchannel heat dissipation cold plate, one surface of the paraffin liquid cooling device is connected to a heat source, and the other surface of the paraffin liquid cooling device is connected to the microchannel heat dissipation cold plate:

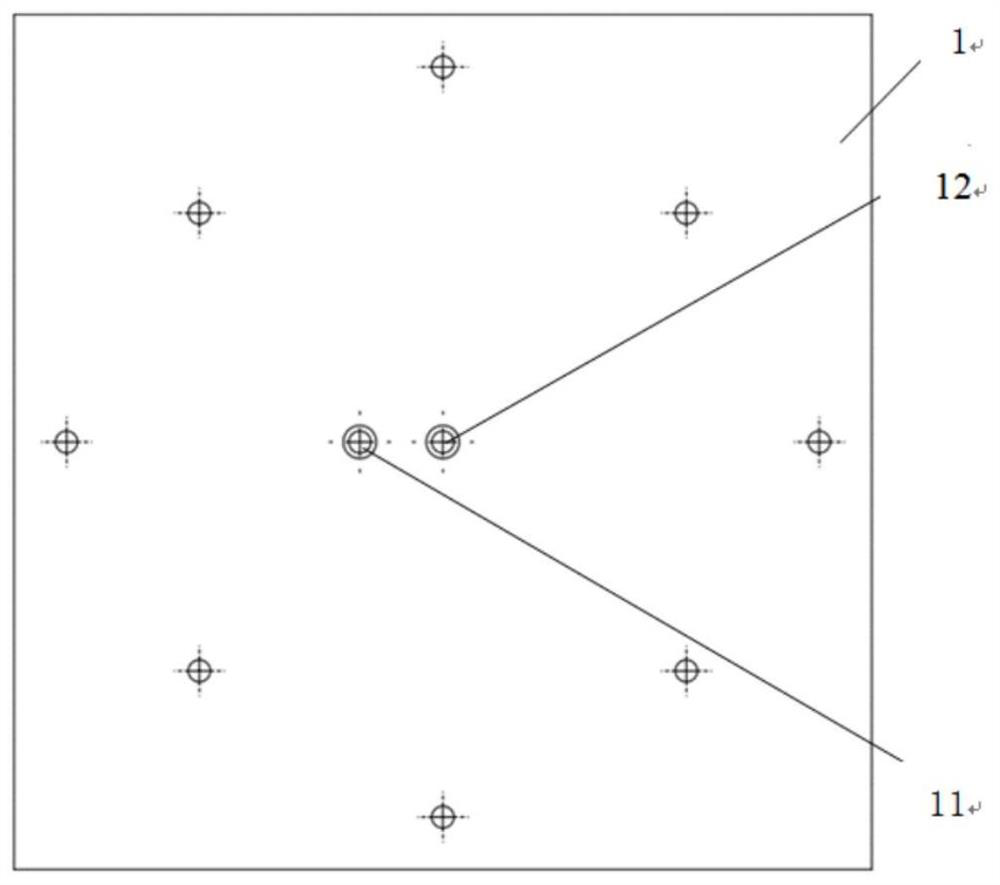

[0044] The microchannel heat dissipation cold plate includes a heat dissipation cover 1, a transitional cold plate 2 and a heat sink cold plate 3 connected in sequence; the heat dissipation cover 1 is provided with a cover liquid inlet 11 and a liquid outlet 12, and the outlet The liquid port 12 is arranged at the center of the cover plate, and the liquid inlet 11 of the cover plate can be arranged near the liquid outlet 12, such as figure 2 shown.

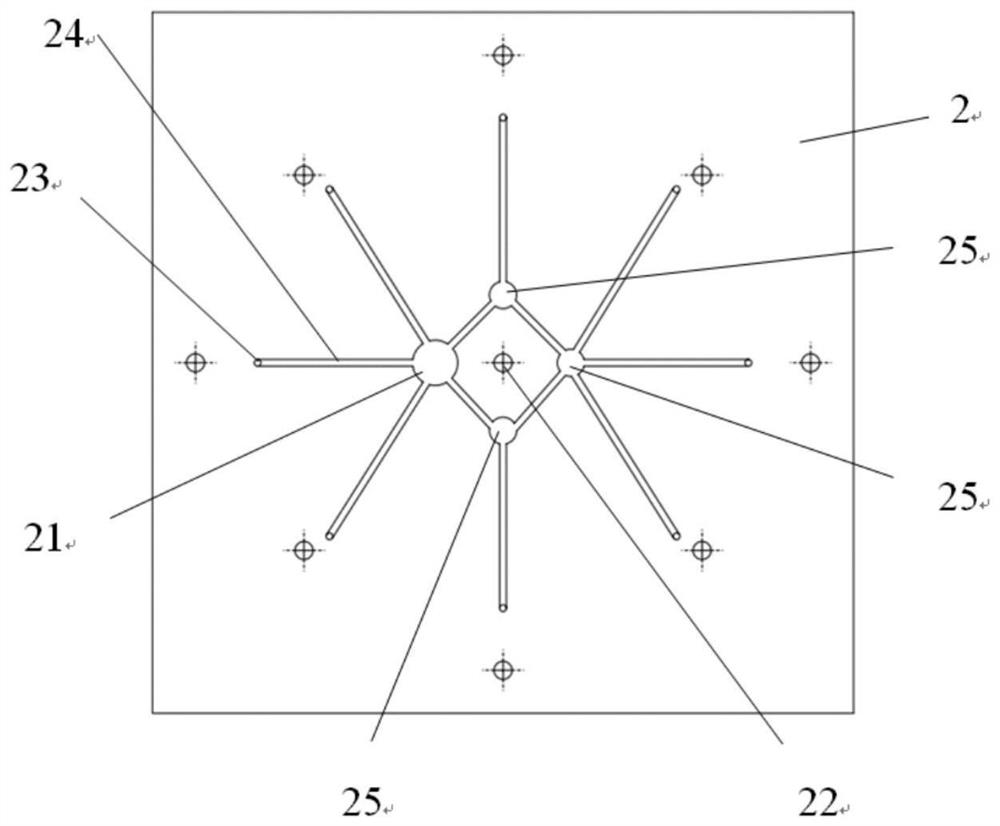

[0045] The transitional cold plate 2 is provided with a transitional liquid inlet 21, a confluence outlet 22, a number of intermediate transitional inlets 23 and a number of str...

Embodiment 2

[0052] This embodiment is based on Embodiment 1. The main flow channel 33 and the branch flow channel 34 in the heat sink cold plate 3 finally form a structure similar to a spider web. The 67.5° between the main flow channel 33 and the branch flow channel 34 is evenly distributed on both sides With numerous branch channels 34, the size of the entire heat sink cold plate 3 is 155mm*150mm*2mm, the inner diameter of the liquid inlet 31 is 4mm, the outer diameter is 6mm, the width of the main channel 33 is 2mm, and the height is 1mm. The width of the branch flow channel 34 can also be gradually increased toward the direction of the confluence port 31, the distance between the two branch flow channels 34 is 4.62 mm, the size of the innermost branch flow channel 34 is 2.49 mm, and the second layer of branch flow channels 34 is 1.39mm, the width of the third branch flow channel 34 is 1.57mm, the width of the fourth layer branch flow channel 34 is 1.75mm, and the branch flow channel 34...

Embodiment 3

[0054] In this embodiment, the performance of the microchannel heat dissipation cold plate is described.

[0055] Experiment 1 (for the same split channel width)

[0056] Experimental conditions: the micro-channel heat dissipation cold plate is made of aluminum, and the cooling liquid is clear water. The entrance condition is: the speed entrance is 0.5m / s. Outlet conditions: pressure outlet, the reference pressure adopts standard atmospheric pressure. Heating device: A heat source with a size of 120mm*67mm*2mmd is attached to the bottom of the micro-channel heat dissipation cold plate, and the heating power of the heat source is 150W.

[0057] Simulation results:

[0058] The surface temperature distribution is as Image 6 As shown, the peak temperature of the wall surface of the microchannel heat dissipation cold plate is 306.4578K, and the minimum temperature is 300K, the temperature difference is small and the temperature is relatively uniform.

[0059] The flow veloci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com