Continuous deslagging method and system

A residue and material liquid technology, applied in the field of continuous slag discharge methods and systems, can solve the problems of unfavorable residue lifting and removal, reducing the slag discharge effect, etc., and achieve the effects of simple structure, automatic control, and avoidance of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

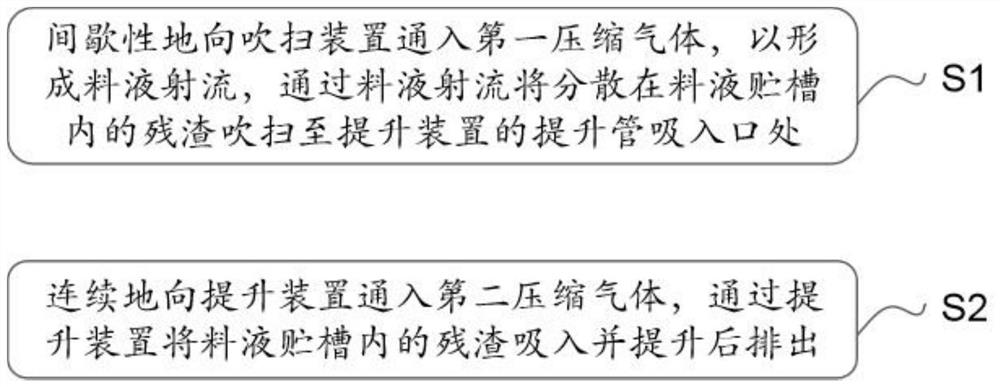

[0048] like figure 1 As shown, the present embodiment discloses a continuous slagging method, comprising:

[0049] S1, intermittently feed the first compressed gas into the purge device placed in the feed liquid in the feed liquid storage tank, so that the feed liquid entering the purge device is sprayed to form a feed liquid jet, and passes through the feed liquid jet Sweep the residue dispersed in the feed liquid storage tank to the suction port of the riser of the lifting device;

[0050] S2, continuously feed the second compressed gas into the lifting device, so as to suck the residue in the feed liquid storage tank through the suction port of the lifting pipe of the lifting device and discharge it after being lifted.

[0051]This embodiment also discloses a continuous slagging system, including a purge unit, a lifting unit and a control unit, the purge unit includes a purge device, the lifting unit includes a lifting device, the control unit includes a time controller, t...

Embodiment 2

[0054] like figure 1 As shown, the present embodiment discloses a continuous slagging method, comprising:

[0055] S1, intermittently feed the first compressed gas into the purge device placed in the feed liquid in the feed liquid storage tank, so that the feed liquid entering the purge device is sprayed to form a feed liquid jet, and passes through the feed liquid jet Sweep the residue dispersed in the feed liquid storage tank to the suction port of the riser of the lift device.

[0056] Further, step S1 specifically includes the following steps:

[0057] S101, injecting the first compressed gas into the compressed air tank until the gas pressure in the compressed tank reaches a preset pressure threshold and volume threshold.

[0058] In this embodiment, the first compressed gas is compressed air. The pressure threshold and volume threshold in the pressure tank refer to the pressure and gas volume of the first compressed gas required to completely (ideally) or mostly eject...

Embodiment 3

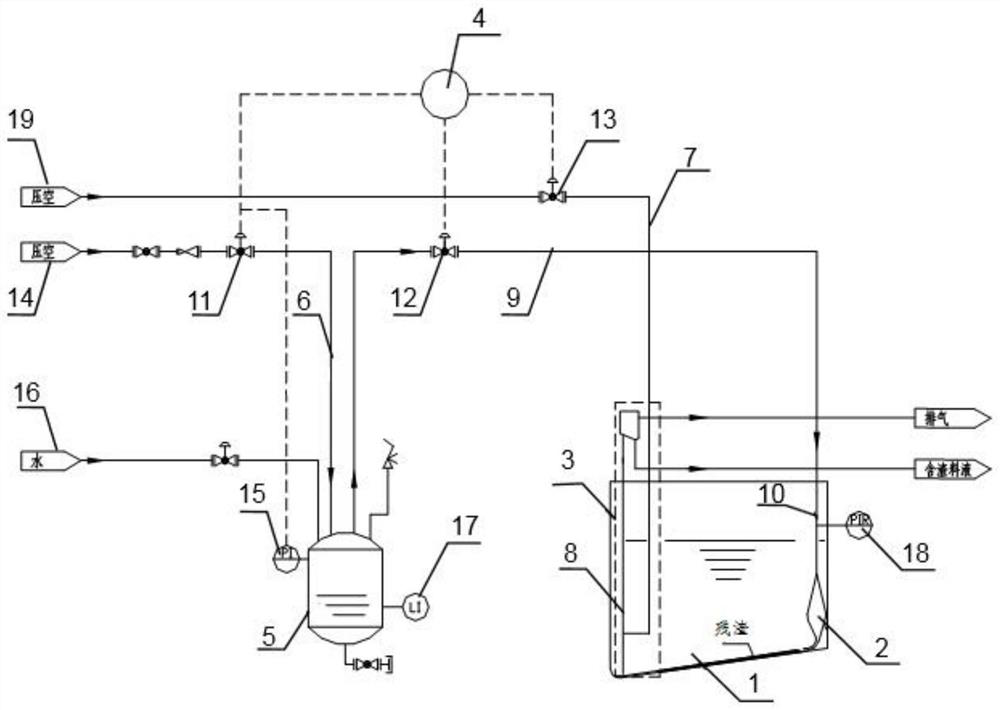

[0070] like figure 2 As shown, this embodiment discloses a continuous slagging system, which can be used in the continuous slagging method described in Example 1. The system includes a purging unit, a lifting unit and a control unit. The purging unit includes a purging device 2 , and the lifting unit includes a lifting device 3 .

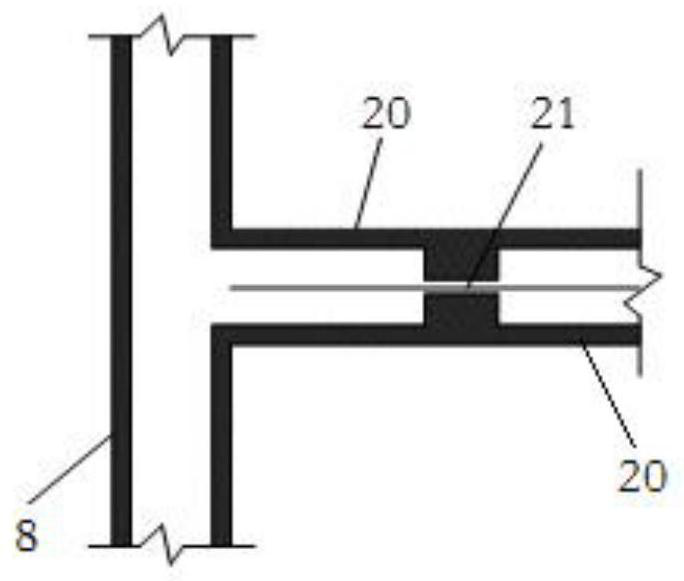

[0071] The purging device 2 includes a nozzle, and the lifting device 3 includes a second air inlet pipe 7 and a rising pipe 8, wherein the control unit is connected with the purging unit for controlling the introduction of the first compressed gas into the purging device 2, so that the entering The feed liquid in the purging device 2 is sprayed from the nozzle to form a feed liquid jet, and the residue dispersed in the feed liquid storage tank is blown to the suction port of the riser pipe 8 of the lift device 3 through the feed liquid jet; the control unit It is also connected with the lifting device 3, and is used to control the introduction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com