Ammonium persulfate system etching solution for etching TFT copper-molybdenum alloy layer

An ammonium persulfate and etching solution technology is applied in the field of chemical etching of metal materials, which can solve the problems of harmful nitrogen and oxygen gases and do not allow nitrate, and achieve stable etching process, good etching parameters, and long etching solution life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

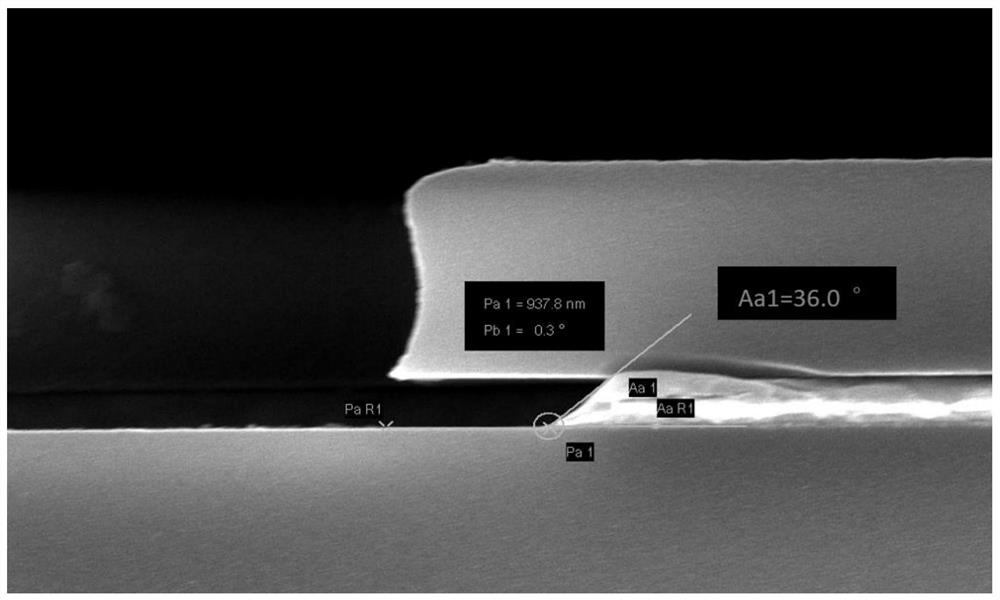

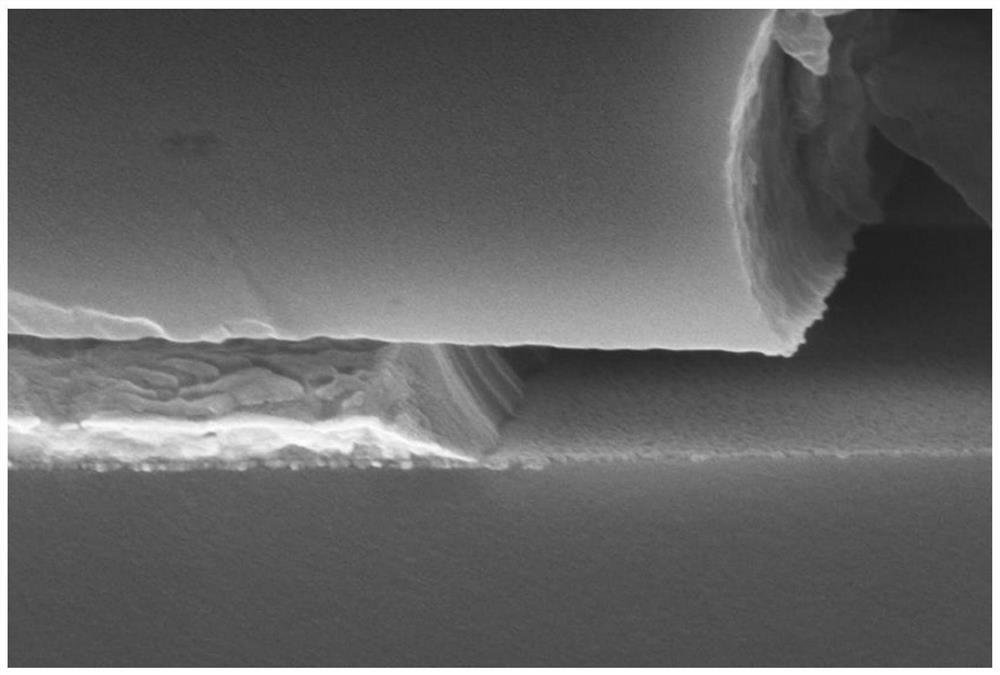

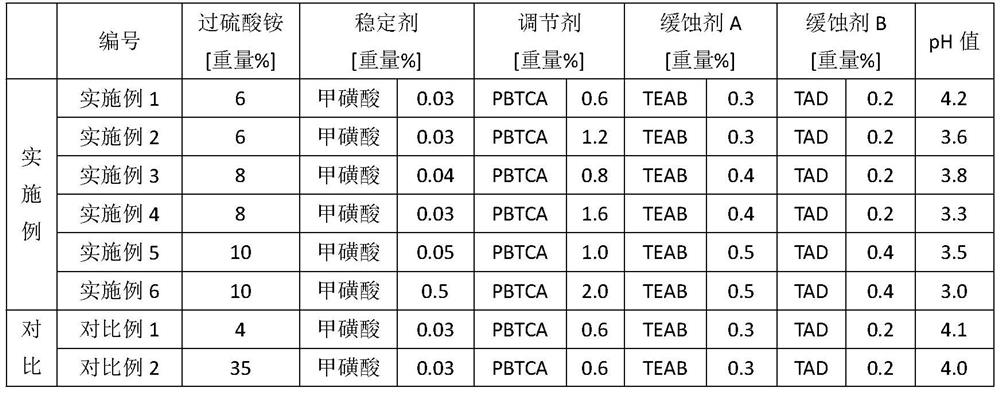

[0055] Wherein the TFT substrate scanning electron microscope sectional view of embodiment 1 etchant etching is as figure 1 , the etching angle is 36.0°, the CDloss is 0.94um, and the straightness of the etching slope is good. The top view of the TFT scanning electron microscope etched by the etching solution of embodiment 1 is as figure 2 , it can be clearly seen that the etched substrate has no molybdenum residue and no undercut.

[0056] The etchant etching situation of comparative example is as follows:

[0057] The amount of ammonium persulfate is lower than 5% of the etching solution of Comparative Example 1, and the etching angle of the TFT substrate obtained by etching is greater than 50°.

[0058] The amount of ammonium persulfate is higher than 30% of the etching solution of Comparative Example 2, the etching angle of the TFT substrate obtained by etching is less than 30°, the CDloss is greater than 1.10um, and the straightness of the etching slope is not good.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com