High solids coating and process for coating

A high-solid coating, solid technology, applied in the direction of polyester coating, polyurea/polyurethane coating, coating, etc., to achieve the effect of excellent color consistency, improved stability, excellent rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example A-C

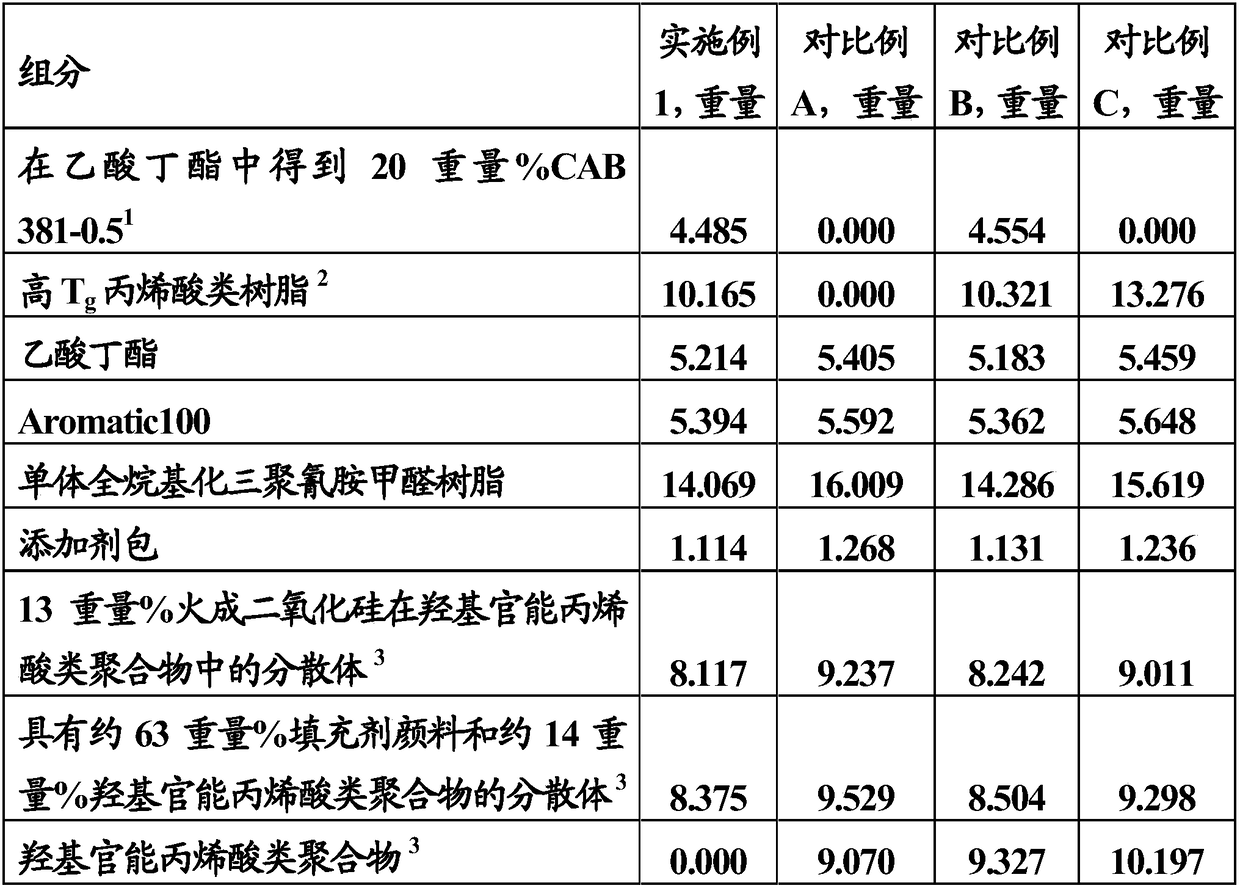

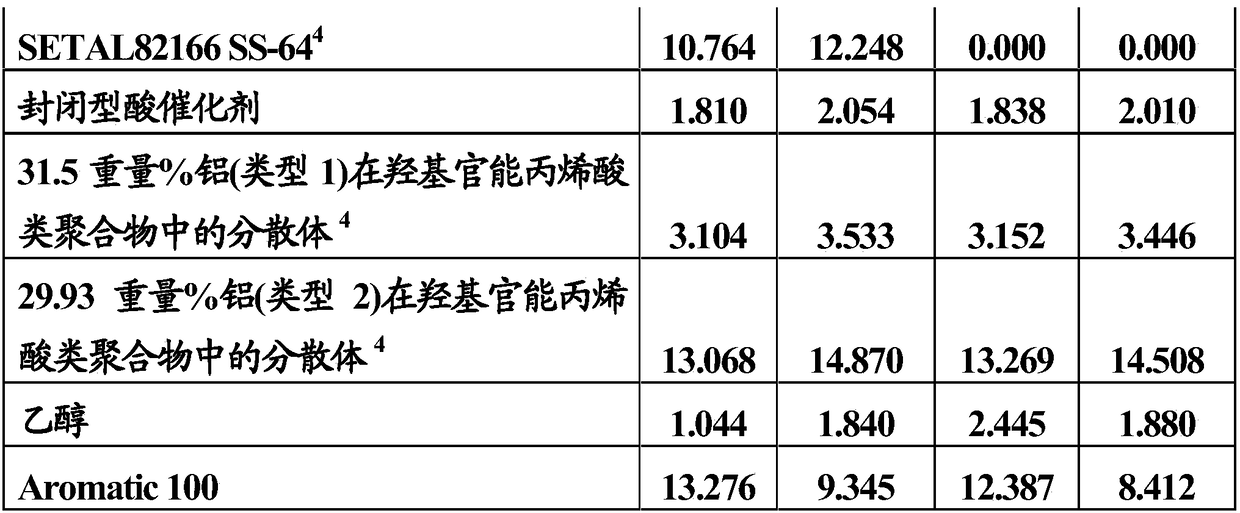

[0100] Basecoat coating compositions were prepared using the ingredients shown in Table 1. The prepared coating compositions were reduced to a spray viscosity of 21 seconds as measured with a Fisher #2 cup, and the respective non-volatile content was determined by ASTM Test Method D2369 in which the samples were heated at 110°C (230°F) for 60 minute. These values are recorded in Table 2.

[0101] Table 1

[0102]

[0103]

[0104] 1. Obtained from Eastman Chemical Company (high molecular weight cellulose acetate butyrate polymer, 37% by weight butyryl content, 13% by weight acetyl content, 1.5% by weight hydroxyl content, T g 130°C, melting point 155-165°C, viscosity 1.9 poise, as determined by ASTM method D1343 in solution described as Formulation A).

[0105] Polymerization product of 2.2.27 parts by weight of 2-ethylhexyl acrylate, 5.68 parts by weight of methyl methacrylate, 12.10 parts by weight of hydroxymethyl methacrylate, 5.68 parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com