Processing method of strong-flavor peony seed oil

A technology of peony seed oil and processing method, which is applied in the direction of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of peony seed oil not strong enough fragrance, low oil yield of peony seed oil, etc., to achieve Protection of physiological activity, low price, effect of enhancing fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A processing method of Luzhou-flavor peony seed oil, the method comprising the steps of:

[0029] 1) Pretreatment: select fresh peony seeds that are dry, free from diseases and insect pests, and free from mildew, and perform shelling treatment, and put the shelled peony seed kernels into a drying box for drying; the drying temperature is 40°C, The drying time is 1 hour, and the moisture content of peony seeds after drying is 12%;

[0030] 2) Stir-fry: Put the dried peony seed kernels into a frying pan and stir-fry continuously at a temperature of 140°C until the fragrance is released and the skin of the peony seed kernels is separated from the kernels;

[0031] 3) Peeling: Peeling the peony seeds after stir frying;

[0032] 4) Pulverization: crush the peony seeds with a pulverizer, the number of crushed peony seeds is 60 mesh, put the pulverized peony seeds into a drying box for drying, the temperature is 35°C, stir once every 5min, the drying time 6 minutes;

[0033...

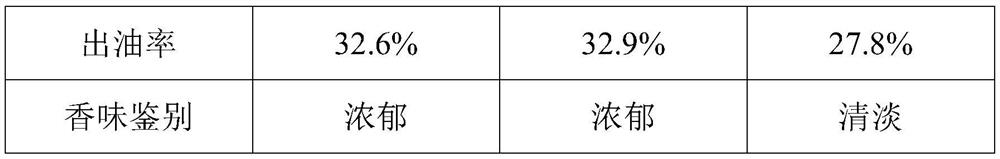

Embodiment 2

[0037] A processing method of Luzhou-flavor peony seed oil, the method comprising the steps of:

[0038] 1) Pretreatment: select fresh peony seeds that are dry, free from diseases and insect pests, and free from mildew, and perform shelling treatment, and put the shelled peony seed kernels into a drying box for drying; the drying temperature is 45°C, The drying time is 2 hours, and the water content of peony seeds after drying is 10%;

[0039] 2) Stir-fry: Put the dried peony seed kernels into a frying pan and stir-fry continuously at a temperature of 150°C until the aroma is released and the skin of the peony seed kernels is separated from the kernels;

[0040] 3) Peeling: Peeling the peony seeds after stir frying;

[0041] 4) Pulverization: crush the peony seeds with a pulverizer, the number of crushed peony seeds is 60 mesh, put the pulverized peony seeds into a drying box for drying at a temperature of 40°C, stir once every 5 minutes, and the drying time 7 minutes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com