Oil-resistant, high-temperature-resistant and low-volatile organic silica gel

A technology of organic silica gel and low volatile content, applied in the field of organic silica gel and its preparation, which can solve the problems of reducing strength and other mechanical properties, affecting the service life of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

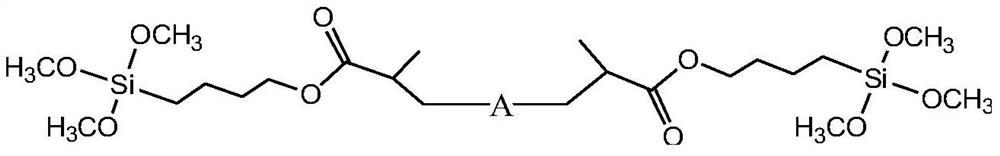

Image

Examples

Embodiment 1

[0033] Methyl vinyl MQ resin (vinyl content 0.5mmol / g, viscosity at 25°C is 7000mPa.S), methyl silicone oil ((Me3 SiO 0.5 ) 2 (Me 2 SiO 0.5 ) m , viscosity at 25°C is 300mPa.S), silane coupling agent 1, silane coupling agent 2, silane coupling agent 3, hydrogen-containing silicone oil ((Me 3 SiO 0.5 ) 2 (Me 2 SiO 0.5 ) m (HMeSiO 0.5 ) n , m=30, n=25, hydrogen content is 8.9mmol / g, viscosity at 25°C is 20mPa.S), white carbon black (specific surface area is 150-200m 2 / g hydrophobic silica), Pt catalyst (vinyl siloxane complex of chloroplatinic acid, platinum content 2000ppm), inhibitor (1-ethynyl-1 cyclohexanol), black color paste by 35 :40:2:0.5:0.5:2:6:0.02:0.02:0.03 weight ratio mixing. After vacuum defoaming, solidify at 150°C for 2h. The properties of the samples are shown in Table 1, and the test methods are shown in Table 1.

Embodiment 2

[0035] Methyl vinyl MQ resin (vinyl content 0.5mmol / g, viscosity at 25°C is 7000mPa.S), methyl silicone oil ((Me 3 SiO 0.5 ) 2 (Me 2 SiO 0.5 ) m , viscosity at 25°C is 300mPa.S), silane coupling agent 1, silane coupling agent 2, silane coupling agent 3, hydrogen-containing silicone oil ((Me 3 SiO 0.5 ) 2 (Me 2 SiO 0.5 ) m (HMeSiO 0.5 ) n , m=30, n=25, hydrogen content is 8.9mmol / g, viscosity at 25°C is 20mPa.S), white carbon black (specific surface area is 150-200m 2 / g hydrophobic silica), Pt catalyst (vinyl siloxane complex of chloroplatinic acid, platinum content 2000ppm), inhibitor (1-ethynyl-1 cyclohexanol), black color paste by 35 :40:1.25:1.25:0.5:2:6:0.02:0.02:0.03 weight ratio mixed. After vacuum defoaming, solidify at 150°C for 2h. The properties of the samples are shown in Table 1, and the test methods are shown in Table 1.

Embodiment 3

[0037] Methyl vinyl MQ resin (vinyl content 0.5mmol / g, viscosity at 25°C is 7000mPa.S), methyl silicone oil ((Me 3 SiO 0.5 ) 2 (Me 2 SiO 0.5 ) m , viscosity at 25°C is 300mPa.S), silane coupling agent 1, silane coupling agent 2, silane coupling agent 3, hydrogen-containing silicone oil ((Me 3 SiO 0.5 ) 2 (Me 2 SiO 0.5 ) m (HMeSiO 0.5 ) n , m=30, n=25, hydrogen content is 8.9mmol / g, viscosity at 25°C is 20mPa.S), white carbon black (specific surface area is 150-200m 2 / g hydrophobic silica), Pt catalyst (vinyl siloxane complex of chloroplatinic acid, platinum content 2000ppm), inhibitor (1-ethynyl-1 cyclohexanol), black color paste by 35 :40:1.25:0.5:1.25:2:6:0.02:0.02:0.03 weight ratio mixing. The properties of the samples are shown in Table 1, and the test methods are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com