Production method and production system for extracting oil in oil sludge

A production system and oil extraction technology, applied in the petroleum industry, by-product vaporization, pyrolysis treatment of sludge, etc., can solve the problems of low technical content, insufficient cracking, short construction period, etc., to improve pyrolysis efficiency, heat Fast and uniform effect, not easy to stick into agglomerates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

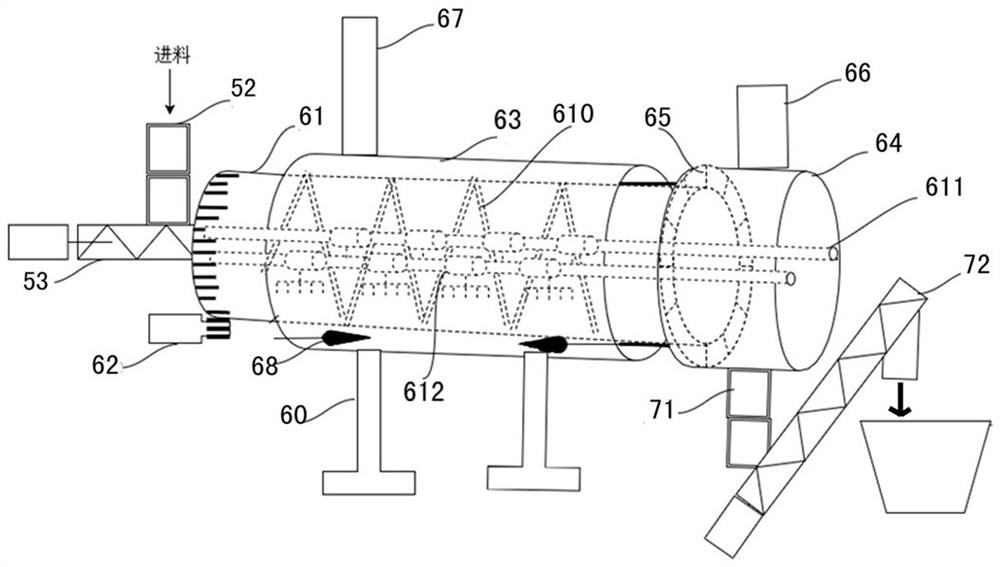

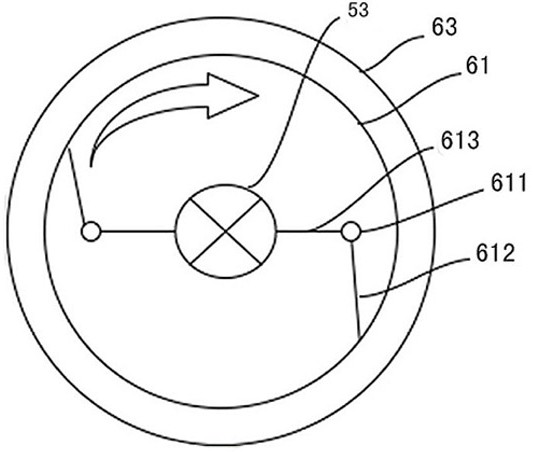

[0052] Figure 1 to Figure 14 Shown is an embodiment of the production system for extracting oil from sludge provided by the present invention.

[0053] see figure 1 , the production system includes a sludge pretreatment device, a feed device 5, a sludge pyrolysis device 6, a slag discharge device 7, and a gas condensation recovery device 9 arranged in sequence according to the sludge treatment process, wherein the sludge pretreatment device includes a raw material sludge crusher 1. Oil sludge three-phase separator 2 and oil sludge pool 3; gas condensation recovery device 9 includes a circulating water condensing device, an oil-water separation device 94, a recovery oil oil tank 4 and a catalytic burner, and the circulating water condensing device is an oil vapor condensing device 91, The closed-loop waterway system formed by the water air cooler 92, the water tank 93 and the negative pressure fan in series through the water pipeline; the oil sludge pyrolysis device 6 is a ro...

Embodiment 2

[0071] The present embodiment is the production method of extracting the oil in the sludge, and the flow process of the method is as follows:

[0072] 1. Pretreatment: The raw material sludge is crushed, and then the crushed sludge is subjected to three-phase separation pretreatment to obtain sludge and recovered oil. The recovered oil is recovered and stored in a recovered oil tank, and the sludge is sent to the sludge pool;

[0073] 2. Feeding: Use a grab bucket to send the sludge in the sludge pool to the feeding device. The feeding device adopts a closed feeding method to intermittently input the sludge into the sludge pyrolysis device. During the feeding process of the sludge pyrolysis device To ensure the airtightness of the feed;

[0074] 3. Pyrolysis treatment: The oil sludge pyrolysis device adopts the structure of the oil sludge pyrolysis device in Example 1, which is a rotary negative pressure oil sludge indirect heating device. The drum in working condition is hea...

Embodiment 3

[0079] The present embodiment is the production method of extracting the oil in the oil sludge, and its difference with embodiment 2 is:

[0080]The feeding device in step 2 adopts the structure of the feeding device in embodiment 1, realizes the intermittent feeding of sludge to the drum in a closed feeding manner, and ensures the airtightness of the feeding process of the drum. When starting to feed, the valve plates of the two hoppers in the feeding double hopper device are closed, and the feeding screw elevator intermittently and quantitatively conveys sludge to the upper hopper. After the quantitative sludge is filled with the upper hopper, the upper valve plate is opened, and the sludge enters the lower hopper After the hopper, close the upper valve plate, and then open the lower valve plate, the sludge is fed into the drum by the feeding screw conveyor, the feed amount of the drum sludge is controlled by controlling the speed of the feeding screw elevator, and the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com