Production device and method for continuously producing 2-bromo-3, 3, 3-trifluoropropene

A technology for trifluoropropene and products, which is applied in the field of continuous production of 2-bromo-3,3,3-trifluoropropene, can solve the problems of low efficiency and yield, poor quality, etc., and improve product quality and The effect of stability, shortening the production cycle, and improving the elimination reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

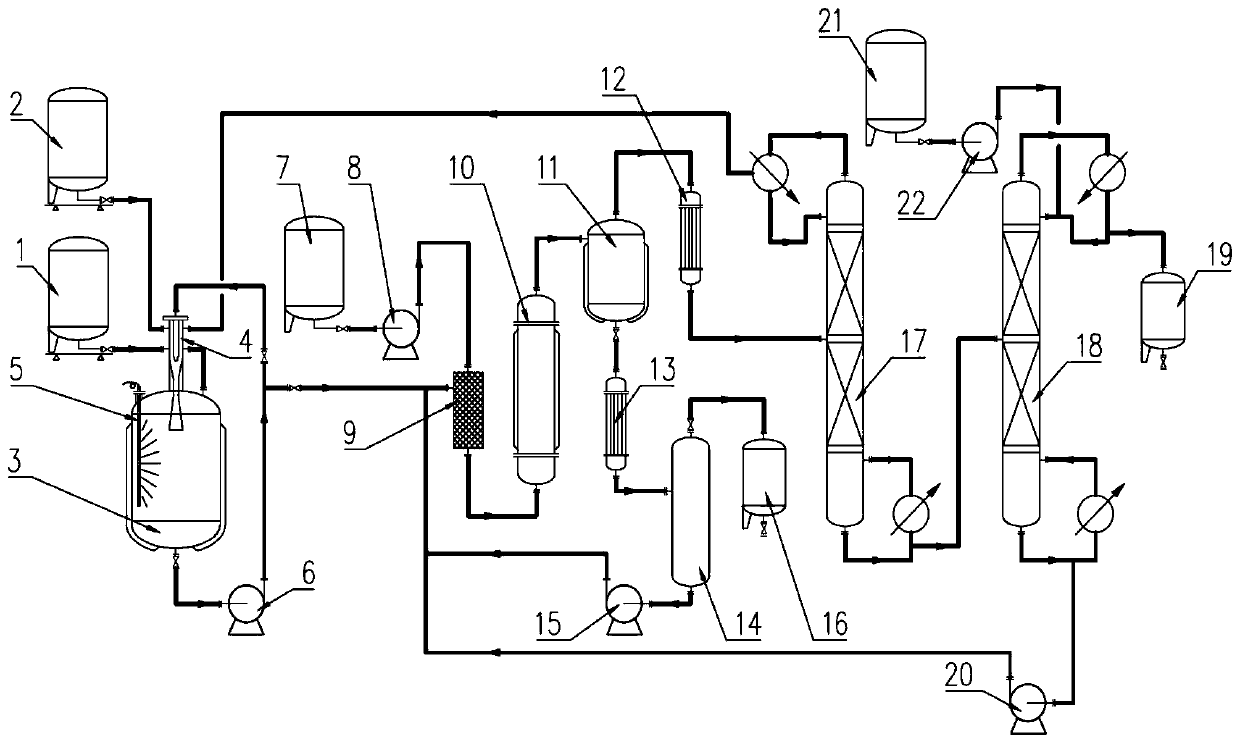

[0038] A device for continuously producing 2-bromo-3,3,3-trifluoropropene, which includes an addition reaction system, an elimination reaction system, a rough separation system and a rectification purification system;

[0039] The addition reaction system comprises a bromine metering tank 1, a trifluoropropylene metering tank 2, an addition reactor 3, a Venturi injector 4, a built-in light source 5, an addition reaction circulation pump 6, and the Venturi injection The device 4 is arranged on the upper end of the addition reactor 3, and the built-in light source 5 is arranged in the addition reactor 3; the bromine metering tank 1 and the trifluoropropylene metering tank 2 are respectively communicated with the suction port of the Venturi injector 4, The outlet at the lower end of the addition reactor 3 communicates with the inlet of the Venturi injector 4 through the addition reaction circulation pump 6 to form an injection circulation reaction loop;

[0040] Described elimina...

Embodiment 2

[0045] A device for continuous production of 2-bromo-3,3,3-trifluoropropene as described in Example 1, the difference is: the elimination reactor 10 is composed of a tower reactor, using jacketed steam Heated and has a built-in spoiler. The number of built-in light sources 5 provided inside the addition reactor 3 is three, and the power of the built-in light sources 5 is 2000W.

Embodiment 3

[0047] A kind of continuous production device of 2-bromo-3,3,3-trifluoropropene as described in Example 1, the difference is: the described elimination reactor 10 is made up of tubular reactor, adopts jacketed steam Heated and has a built-in spoiler. The number of built-in light sources 5 provided inside the addition reactor 3 is five, and the power of the built-in light sources 5 is 1500W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com