Method for preparing dibutyl dithiocarbamate by aid of high-gravity reactor

A technology of dibutyldithiocarbamate and hypergravity reactor, applied in the direction of organic chemistry and the like, can solve the problems of high process labor intensity, poor product quality, serious pollution, etc., so as to shorten the reaction time and production cost. The effect of low and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

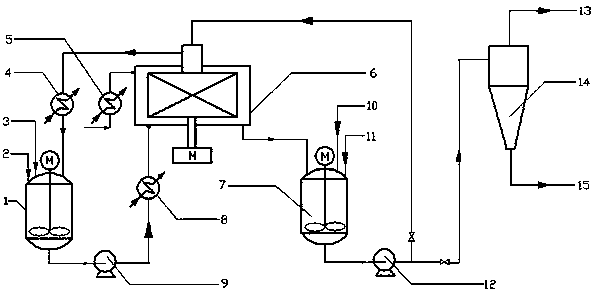

Image

Examples

Embodiment 1

[0035] Put dibutylamine and 30% (wt) sodium hydroxide into a solution with a molar ratio of 1:1 and add it to the batching tank A, and carbon disulfide and methylene chloride into a solution with a molar ratio of 1:0.5 and add it to the batching tank B. The molar ratio of dibutylamine to carbon disulfide is 1:1.1. The temperature of the supergravity reactor was controlled at 60°C, and the rotation speed of the packed bed was adjusted to 1000r / min. Continuously pump the solution in tank A at a flow rate of 50 ml / min, and at the same time, pump the solution in tank B into the vaporization tube at a rate of 50 ml / min, and then enter the supergravity reactor after vaporization. -Liquid countercurrent reaction. The unreacted gas phase is condensed and returned to tank B for continued use, and the slurry containing dibutylamine and sodium hydroxide flows into tank A to participate in circulation. When the decline rate of dibutylamine content in tank A tends to be gentle, pump the ...

Embodiment 2

[0037] The operating conditions are the same as in Example 1, except that 30% (wt) sodium hydroxide is replaced with 30% (wt) potassium hydroxide, and the mol ratio of dibutylamine and carbon disulfide is 1: 1.4 to obtain a clear, transparent light yellow finished product with a purity of It was 99.3% (GC), and the yield was 96.1%.

Embodiment 3

[0039] The operating conditions are the same as in Example 1, except that the temperature of the supergravity reactor is controlled at 75°C, and the rotation speed of the packed bed is adjusted to 1500r / min to obtain a clear and transparent light yellow product with a purity of 98.9% (GC) and a yield of 96.6%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com