A capping device with capping protection

A technology of equipment and capping head, which is applied in the field of capping equipment with capping protection, can solve the problems of broken glass jars, affecting the quality of glass jar materials, rusting, etc., to prevent splashing, improve processing effects, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

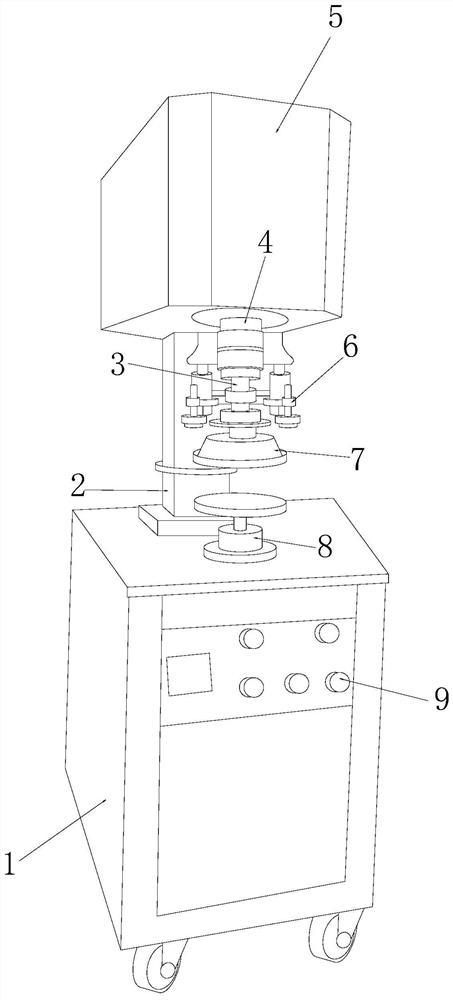

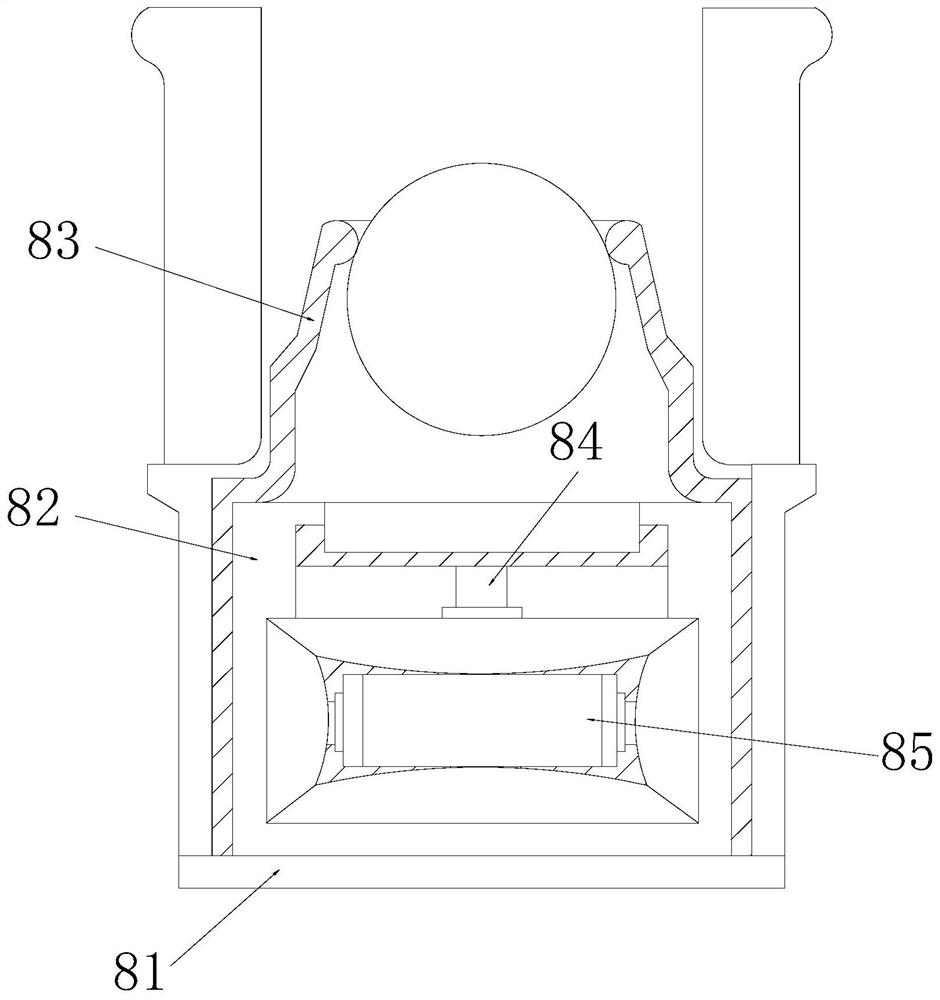

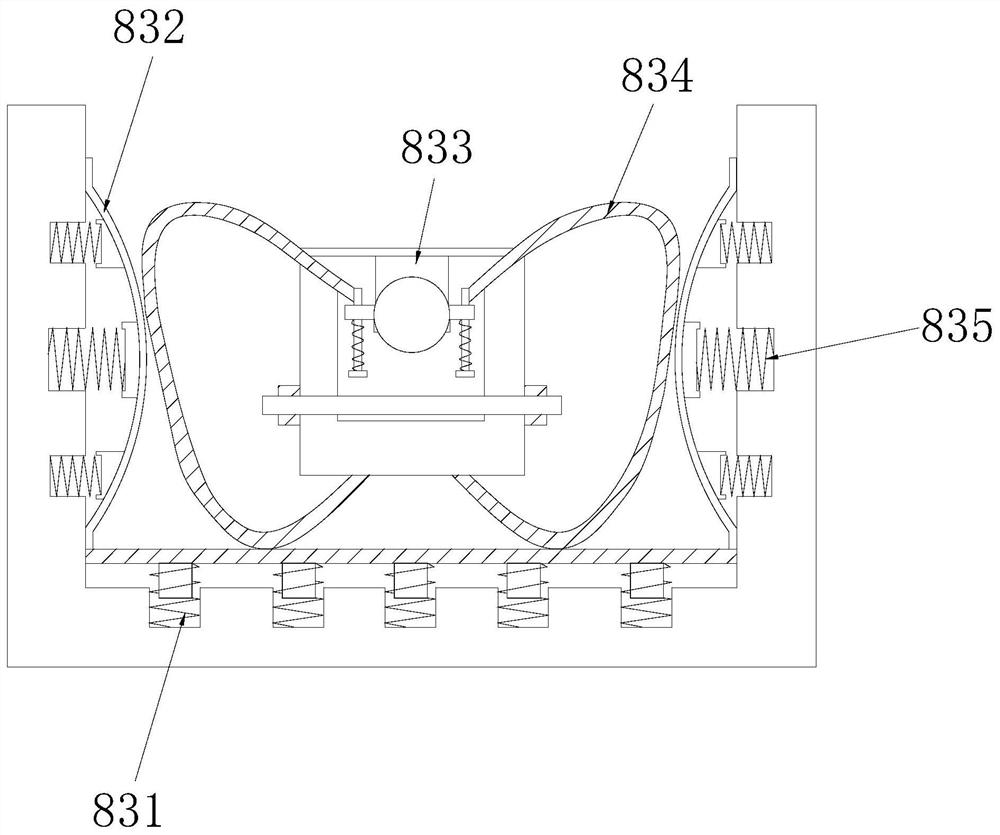

[0033] see figure 1, the present invention provides a technical solution: a capping device with capping protection, its structure includes a body 1, a support column 2, a tightening part 3, a positioning port 4, a mounting seat 5, a limit part 6, a clip Hijab 7, protective device 8, manipulator 9, described body 1 is provided with manipulator 9, and described manipulator 9 is embedded in body 1 inside, and described manipulator 9 is electrically connected with body 1 by electric wire, and described body 1. The support column 2 and the protective device 8 are installed on the top. The support column 2 is screwed and installed on the body 1. The support column 2 and the protective device 8 are arranged on the same straight line. The top of the support column 2 is connected with Mounting seat 5, said mounting seat 5 is vertically inserted and embedded on the support column 2, and the middle position of the bottom of said mounting seat 5 is provided with a positioning port 4, sai...

Embodiment 2

[0045] see figure 1 , the present invention provides a technical solution: a capping device with capping protection, its structure includes a body 1, a support column 2, a tightening part 3, a positioning port 4, a mounting seat 5, a limit part 6, a clip Hijab 7, protective device 8, manipulator 9, described body 1 is provided with manipulator 9, and described manipulator 9 is embedded in body 1 inside, and described manipulator 9 is electrically connected with body 1 by electric wire, and described body 1. The support column 2 and the protective device 8 are installed on the top. The support column 2 is screwed and installed on the body 1. The support column 2 and the protective device 8 are arranged on the same straight line. The top of the support column 2 is connected with Mounting seat 5, said mounting seat 5 is vertically inserted and embedded on the support column 2, and the middle position of the bottom of said mounting seat 5 is provided with a positioning port 4, sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com