Magnetocaloric-pyroelectric composite material as well as preparation method and application thereof

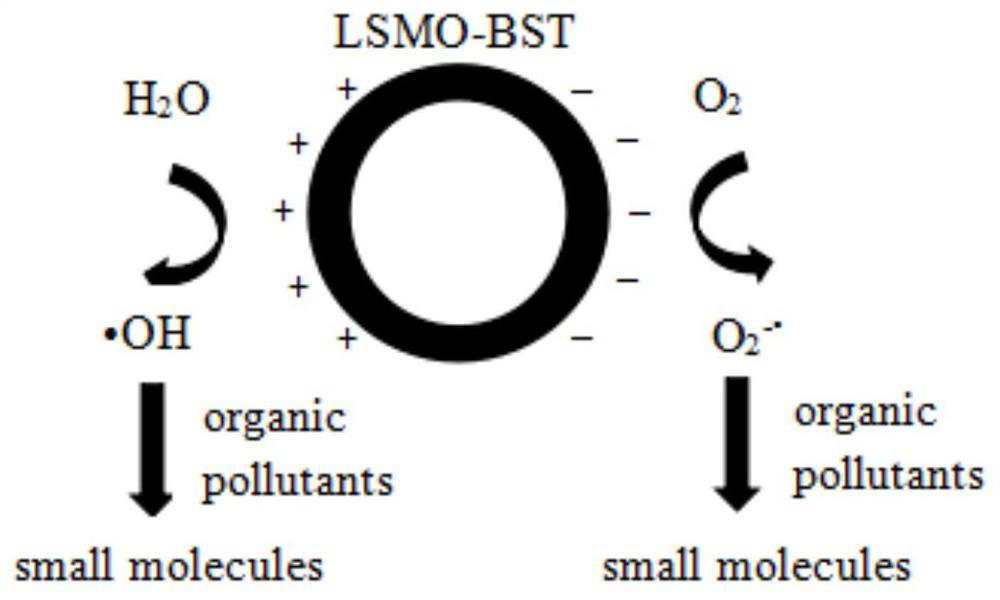

A technology of composite materials and magnetocaloric materials, which is applied in the field of magnetocaloric-pyroelectric composite materials and their preparation, can solve the problem of limited temperature change rate and temperature range, limited catalytic degradation rate of pyroelectric materials, and limited practical Issues such as the scope of application to achieve the effects of improved catalytic efficiency, low loss, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

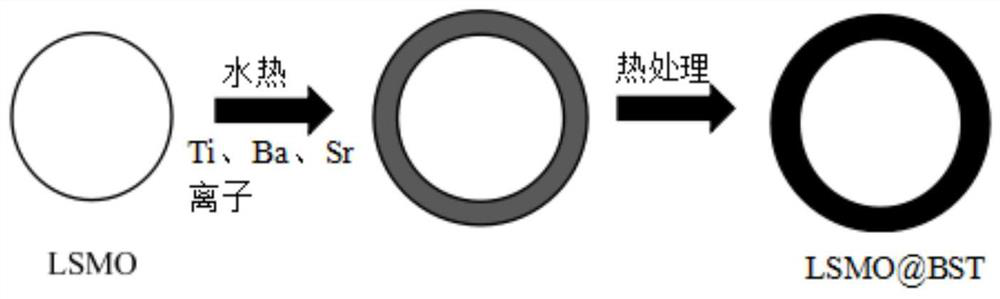

[0041] This embodiment takes magnetocaloric-pyroelectric nano core-shell structure material as an example, La 0.7 Sr 0.3 MnO 3 (LSMO) nanoparticles are the core material of the core-shell structure, Ba 0.7 Sr 0.3 TiO 3 (BST) is the shell layer. The magnetocaloric material is synthesized by the sol-gel method, and then the pyroelectric material shell is wrapped around the magnetocaloric material by the hydrothermal method. The schematic diagram of its preparation is shown in image 3 shown.

[0042] La 0.7 Sr 0.3 MnO 3 (LSMO) preparation: use lanthanum nitrate, strontium nitrate, and manganese nitrate as raw materials, dissolve in deionized water according to the molar ratio of 0.7:0.3:1, according to the metal ion: citric acid: ethylene glycol = 1:1.5:1.5 Add citric acid and ethylene glycol in proportion, stir vigorously and add ammonia water to adjust the pH to 9, pre-calcine at 300°C for 30 minutes, anneal at 950°C for 4 hours, and grow LSMO particles with good cryst...

Embodiment 2

[0045] In this example, taking the magnetocaloric-pyroelectric nanotube material as an example, a porous alumina template (AAO template) was prepared by anodic oxidation, and La 0.7 Sr 0.3 MnO 3 @Ba 0.7 Sr 0.3 TiO 3 array of nanotubes.

[0046] Preparation of the AAO template: Aluminum foil with a mass fraction higher than 99.999% is used, and the aluminum foil after pretreatment is obtained by successively cutting, annealing, polishing and other treatments. Use 0.3mol / L oxalic acid solution as the electrolyte, aluminum foil as the anode, and carbon rod as the cathode for electrochemical oxidation, each time for 2-10 hours, after the first oxidation, use a mixture of phosphoric acid and chromium oxide to remove the formed The aluminum oxide film was rinsed with distilled water and then oxidized for the second time. The oxidation conditions were the same as the first step, and finally a transparent AAO template was obtained.

[0047] Preparation of LSMO@BST nanotube array...

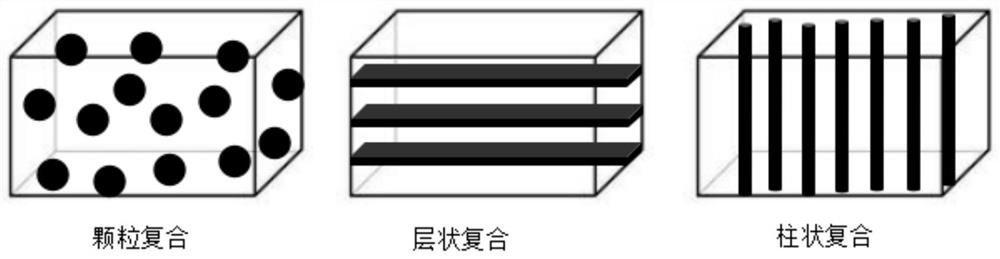

Embodiment 3

[0049] In this example, the pyroelectric nanoparticles are evenly dispersed in the magnetocaloric material, and the magnetocaloric material nanoparticles with good dispersibility are synthesized by the sol-gel method, and then dispersed in the gel of the pyroelectric material, Magnetocaloric material selection La 0.7 Sr 0.3 MnO 3 (LSMO) nanoparticles, pyroelectric material selection Ba 0.7 Sr 0.3 TiO 3 (BST) nanoparticles.

[0050] Use lanthanum nitrate, strontium nitrate and manganese nitrate as raw materials, dissolve them in deionized water according to the molar ratio of 0.7:0.3:1, add citric acid and ethyl alcohol according to the ratio of metal ion: citric acid: ethylene glycol = 1:1.5:1.5 Diol, stir vigorously and add ammonia water to adjust the pH value to 9, pre-calcine at 300°C for 30min, anneal at 950°C for 4h, and grow LSMO particles with good crystallization properties and obvious magnetocaloric effect. Using strontium nitrate, barium nitrate, and tetrabutyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com