Novel suspension type branch crusher

A suspension type, pulverizer technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of easy slippage of twigs, grinding of blades, etc., to avoid inconsistent speed, increase friction, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

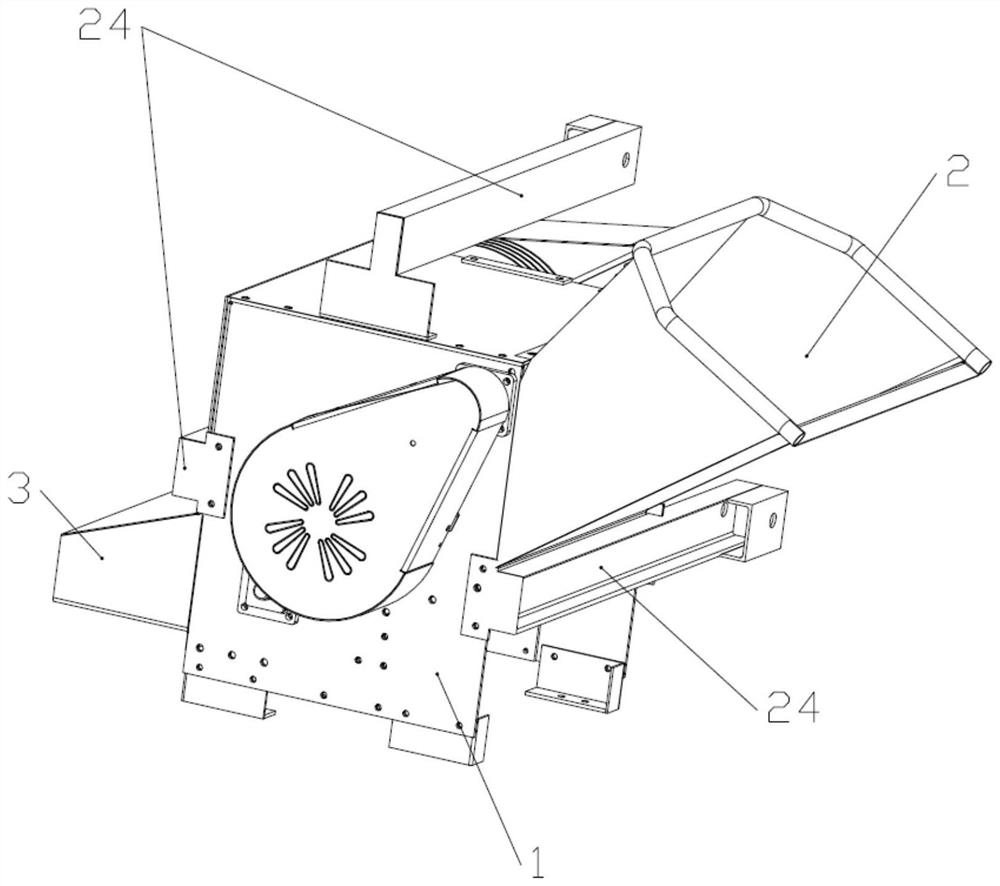

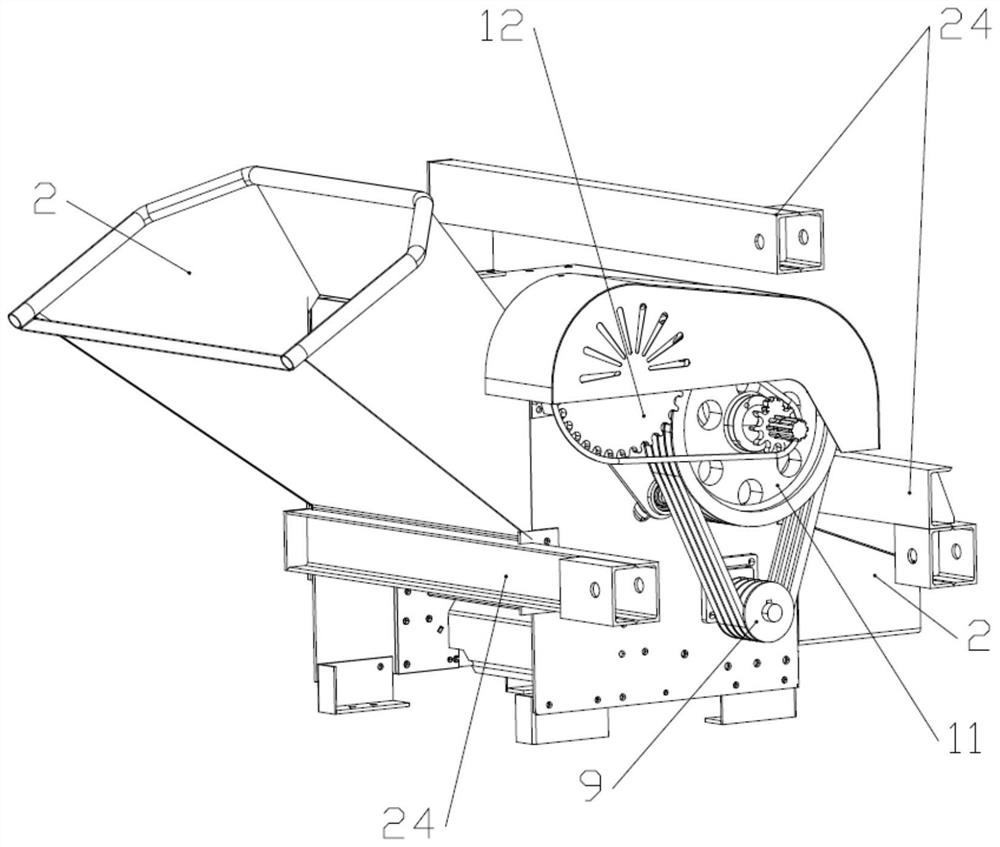

[0046] to combine Figure 1-Figure 4 , it can be seen that the new type of hanging type branch shredder includes a body 1, and one end of the body 1 is a feed end 2, and the other end of the body 1 is a discharge end 3. Wherein the feeding end 2 is an inclined funnel, so the feeding port of the feeding end 2 is relatively large, thereby facilitating feeding.

[0047] At the same time, the pulverizer also includes a cutting assembly, and the cutting assembly is arranged in the machine body 1 and is located between the feeding end 2 and the discharging end 3 . Therefore, in actual use, branches come in from the feed end 2, pass through the cutting assembly to be shredded, and then go out from the discharge end 3.

[0048] Wherein the length of the discharge end 3 is compared with the discharge end 3 of the reference document in the background technology, the length of the present invention is longer, that is, the length of a transition section is added instead of directly exiti...

Embodiment 2

[0074] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that: the front or rear end of the body 1 is provided with wheels, and the body 1 is provided with or externally connected with a driving source 2 that drives the wheels to rotate, and the body is rotated by the wheels. 1 move.

[0075] Wherein the driving source 2 can be a motor, thereby being arranged on the body 1; or the driving source 2 is a tricycle, a tractor, etc., and then pulls the body 1 to move through traction parts such as ropes.

[0076] Therefore, in actual use, the machine body 1 can be moved by driving the wheels to rotate through the driving source 2 . Simultaneously for comfort, thus can be provided with seat, armrest etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com