Current collecting member for cylinder body plating apparatus and plating apparatus

A coating device and cylinder technology, applied in the direction of contact devices, electrolytic components, electrodes, etc., can solve the problems of difficult flow of current, degradation of plating solution, heat generation, etc., to prevent high temperature heat generation, excellent conductivity and durability, The effect of preventing sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

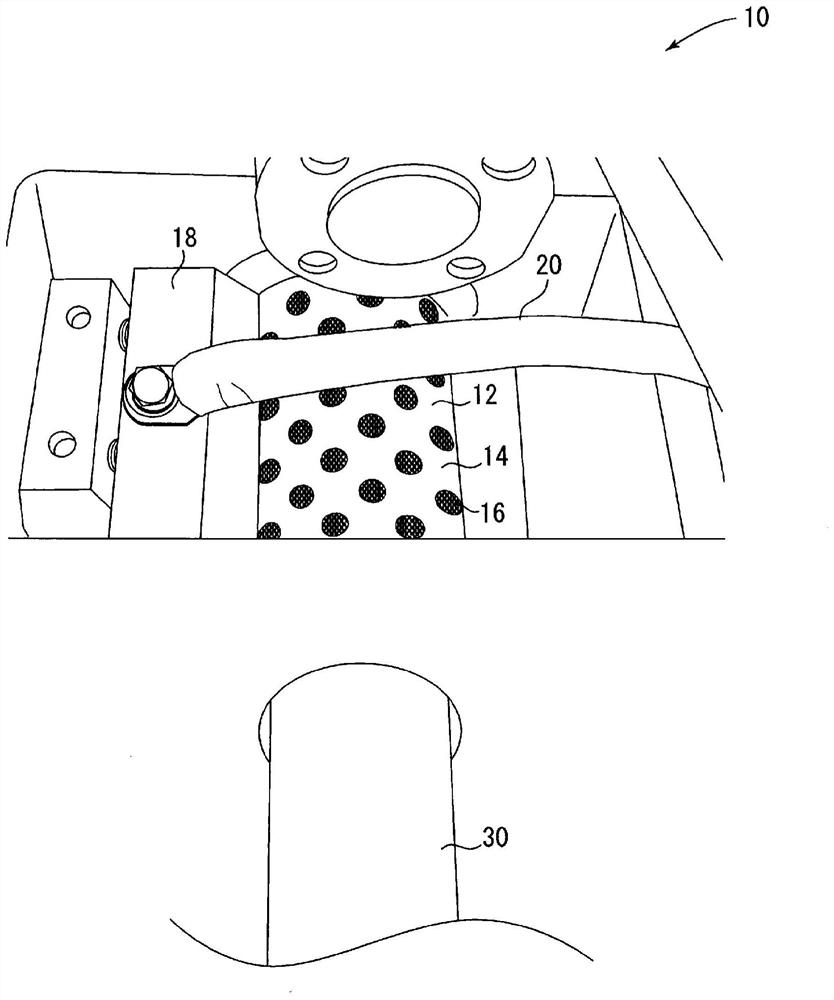

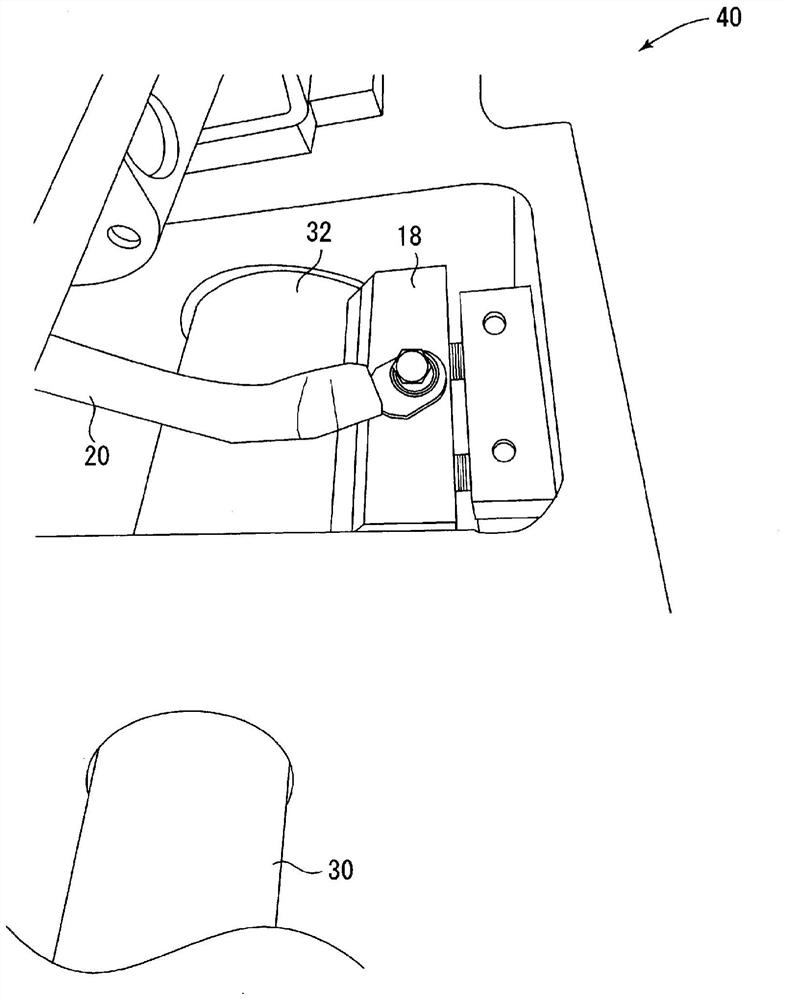

[0042] As a cylinder plating device, in addition to figure 1 Except for the illustrated structure, an apparatus having basically the same structure as a conventional cylinder plating apparatus was used. A current collecting member 12 is used at the base end of the mandrel of the collet cone. As the current collecting member 12, SPB-7590100 manufactured by Oiles Industry Co., Ltd. was used. As the plating solution, a chromium plating solution having a chromic acid concentration of 250 g / L and a sulfuric acid concentration of 2.5 g / L was used.

[0043] Use a cylindrical base material with an aluminum core of 800mm in circumference and 1250mm in surface length as the cylinder to be treated. Clamp both ends of the cylinder to be treated and install it in the plating tank so that the chrome plating solution overflows to be treated. The tank is completely submerged. The rotational speed of the cylinder to be processed is set to 100 rpm, the temperature of the plating solution is ...

Embodiment 2

[0051] use figure 1 The device of the configuration shown was used as the plating device. A current collecting member 12 is used at the base end of the mandrel of the collet cone. As the current collecting member 12, SPB-7590100 manufactured by Oiles Industry Co., Ltd. was used. A copper plating solution comprising 200 g / L of copper sulfate, 100 g / L of sulfuric acid, and 100 mg / L of chloride ions was used as the plating solution.

[0052] Use a cylindrical base material with a circumference of 800mm and a surface length of 1250mm as the cylinder to be treated. Clamp both ends of the cylinder to be treated and install it in the plating tank so that the copper plating solution overflows to be treated. The tank is completely submerged. The rotational speed of the cylinder to be processed was set at 250rpm, the temperature of the plating solution was 45°C, the current density was 30A / dm2 (current 3000A), and the voltage was 6V. Plating treatment was carried out for 10 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com