Balanced heat dissipation liquid cooling system for power battery based on thermal shrinkage material and control method thereof

A power battery and heat dissipation liquid technology, which is applied in the field of thermal management of power batteries for new energy vehicles, can solve problems such as the inability to effectively reduce the temperature rise and temperature difference of single batteries, the slow heat dissipation process, and the inability to effectively reduce the temperature difference of battery modules in a timely manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure and working principle of a heat-shrinkable material-based balanced heat dissipation liquid cooling device for power batteries of the present invention will be further described below with reference to the accompanying drawings.

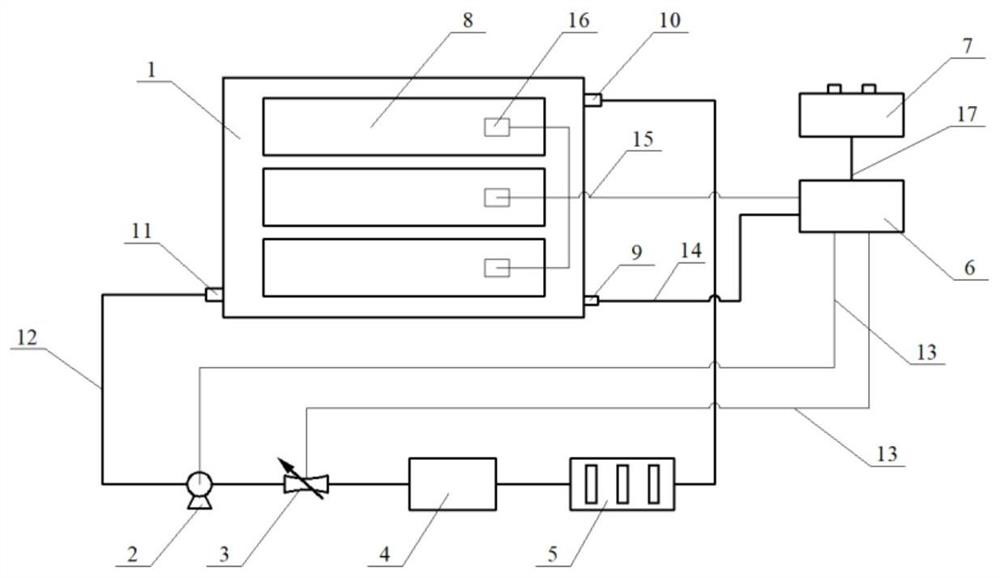

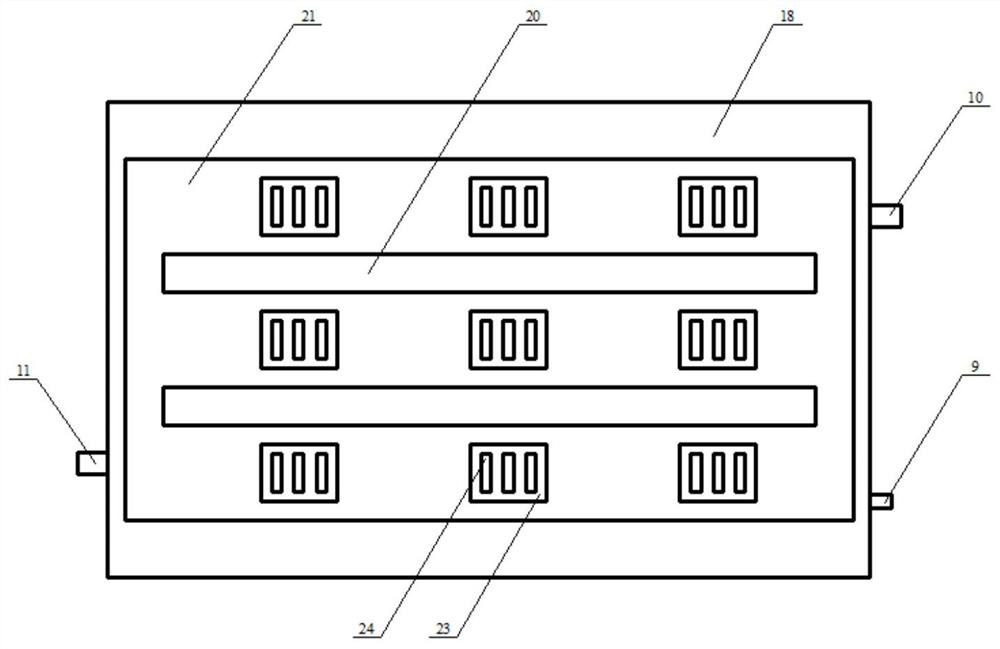

[0021] Such as figure 1As shown, the embodiment of the present invention provides a fast and balanced heat dissipation liquid cooling system for power batteries based on the Peltier effect, including: a cooling liquid circulation system and a temperature control system, and the cooling liquid circulation system includes a liquid cooling plate 1 , a water inlet 11, a water outlet 10, a water pump 2, a pressure relief valve 3, a water storage tank 4, a radiator 5 and a water pipe 12, the temperature control system includes a battery module 8, a storage battery 7, a controller 6, a power cord 17, High voltage control interface 9 , high voltage control line 14 , low voltage control line 13 , temperature sensor 16 and temperature infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com