Lithium battery positive electrode material, preparation method thereof and all-solid-state lithium battery

A technology for positive electrode materials and positive electrode active materials, which is applied in the field of all-solid lithium batteries, lithium battery positive electrode materials and their preparation, and can solve problems such as high-temperature reactions between solid electrolytes and positive electrode active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In a second aspect, the present invention provides a method for preparing the above-mentioned positive electrode material for a lithium battery, comprising the following steps:

[0043] 1) Preparation of sol: Al(NO 3 ) 3 Aqueous solution, adding one or more of basic compounds such as ammonia water, sodium hydroxide, potassium hydroxide and other basic compounds to adjust the pH to 7.5-10.8 to obtain hydrated alumina sol;

[0044] 2) Preparation of positive electrode material precursor: The molar ratio of lithium source, positive electrode active material and sol obtained in step (1) is 1-x: 5+y / 3 (0≤x≤0.1, 0≤y≤x ) to mix, heat to 60-80°C, and add positive electrode active material after it is uniformly dispersed, wherein, the molar ratio of lithium source to positive electrode active material is (0.0003-0.1):1, and stir at 60-80°C for 1 -24h, and dry at 80-150°C for use to obtain the precursor of the positive electrode material;

[0045] 3) Preparation of positive el...

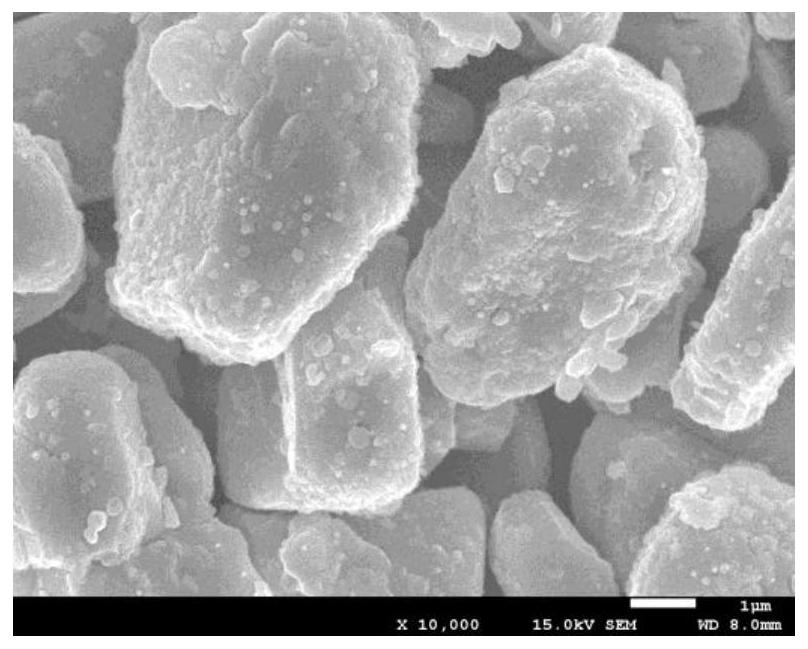

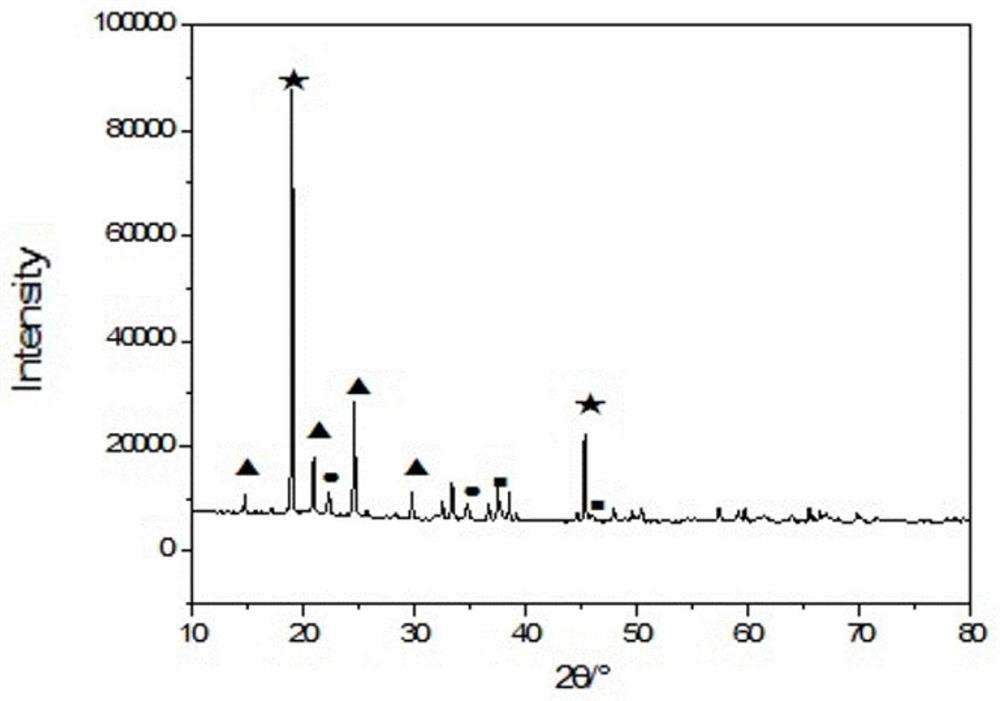

Embodiment 1

[0064] The active material is LiCoO 2 , coated in LiCoO 2 The material on the particle surface is LiAlO 2 and LiAl 5 o 8 , where LiCoO 2 with LiAlO 2 and LiAl 5 o 8 The mass ratio is 100:8:3;

[0065] The specific synthesis method is:

[0066] 1) Preparation of sol: use 100mL H 2 O dissolves 32.51g Al(NO 3 ) 3 , Place the solution in a three-necked flask, slowly add ammonia water drop by drop while stirring, the end point of the addition is pH=8. After the dropwise addition, the solution gradually became a milky white suspension, and the colloid obtained after the suspension was filtered and washed was hydrated alumina sol (30wt% Al 3+ );

[0067] 2) Preparation of cathode material precursor: take 10g LiCoO 2 , 1.590 g of the hydrated alumina sol prepared above, 0.317 g of lithium hydroxide and 50 mL of ethanol were put into a three-necked flask, placed in a water bath at 80°C for condensing and reflux for 5 hours, filtered and washed the precipitate, and dried f...

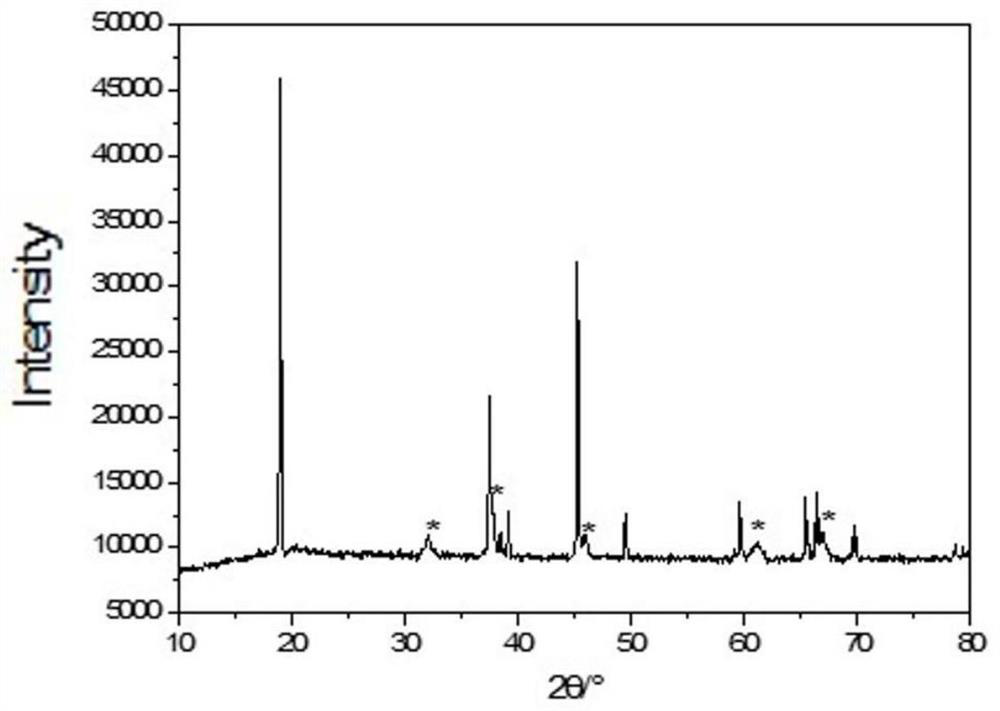

Embodiment 2

[0072] The active material is LiNi 0.8 co 0.1 mn 0.1 o 2 , coated in LiNi 0.8 co 0.1 mn 0.1 o 2 The material on the particle surface is LiAlO 2 and Li 0.517 Al 5.161 o 8 , where LiCoO 2 with LiAlO 2 and Li 0.517 Al 5.161 o 8 The mass ratio is 100:8:3;

[0073] The specific synthesis method is:

[0074] 1) Sol preparation: use 100mL H 2 O dissolves 32.51g Al(NO 3 ) 3 , Place the solution in a three-necked flask, slowly add ammonia water drop by drop while stirring, the end point of the addition is pH=8. After the dropwise addition, the solution gradually became a milky white suspension. The colloid obtained after suction filtration and washing of the suspension is the hydrated alumina sol (30wt% Al 3+ );

[0075] 2) Preparation of cathode material precursor: take 10g LiNi 0.8 co 0.1 mn 0.1 o 2 1.605 g of the hydrated alumina sol prepared above, 0.304 g of lithium hydroxide and 50 mL of ethanol were put into a three-necked flask, and placed in a water b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com