Magnetic core for high-frequency high-impedance ignition coil

An ignition coil, high impedance technology, applied in the direction of transformer/inductor magnetic core, inductor, inductive energy storage device, etc., can solve problems such as the stability of the magnetic core affecting the ignition coil, unstable connection, etc., to improve the stability , the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

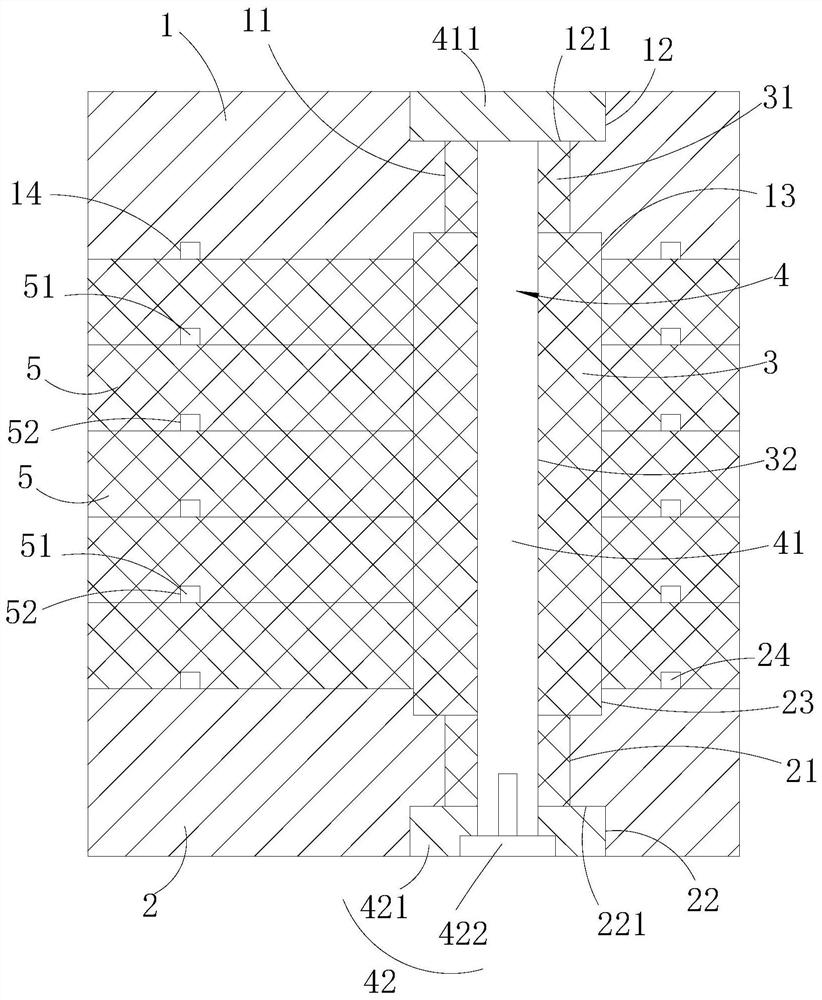

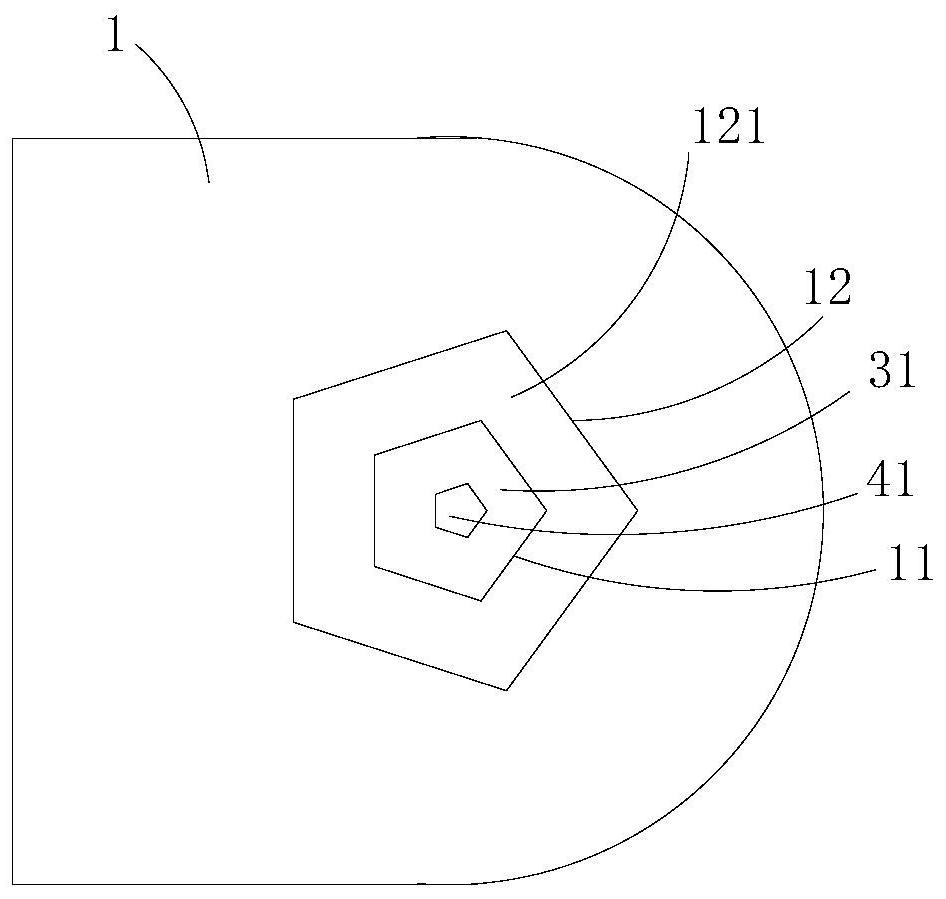

[0038] Such as Figure 1 to Figure 3 As shown, the present invention provides a magnetic core for a high-frequency high-impedance ignition coil, including: a first end cap 1 and a second end cap 2 arranged at intervals, and the first end cap 1 is provided with a non-circular The first positioning through hole 11, the second end cover 2 is provided with a non-circular second positioning through hole 21; the magnetic post 3, the magnetic post 3 is arranged on the first end cover 1 and the second end cover 1 Between the two end caps 2, the two ends of the positioning column are provided with positioning parts 31, and the two positioning parts 31 extend into the first positioning through hole 11 and the second positioning through hole correspondingly. 21, and a non-circular perforation 32 is provided in the magnetic column 3; a positioning member 4, the positioning member 4 includes a positioning rod 41 and a fixing part 42, and one end of the positioning rod 41 is provided with a...

Embodiment 2

[0041] The difference between this embodiment and the foregoing embodiments is that;

[0042] Such as Figure 1 to Figure 3As shown, in some embodiments of the present invention, the side of the first end cap 1 away from the second end cap 2 is provided with a first limiting groove 12 communicating with the first positioning through hole 11 , the first limiting groove 12 is non-circular, and the bottom surface of the first limiting groove 12 defines a first limiting table 121 , and the positioning head 411 is embedded in the first limiting groove 12 Inside, and the positioning head 411 stops against the first limiting platform 121 . In this way, the positioning head 411 is prevented from being exposed to the outside, and the flatness of the first end cover 1 is ensured, which is convenient for installation and fixing.

[0043] In some embodiments of the present invention, the side of the second end cap 2 away from the first end cap 1 is provided with a second limiting groove...

Embodiment 3

[0048] The difference between this embodiment and the foregoing embodiments is that;

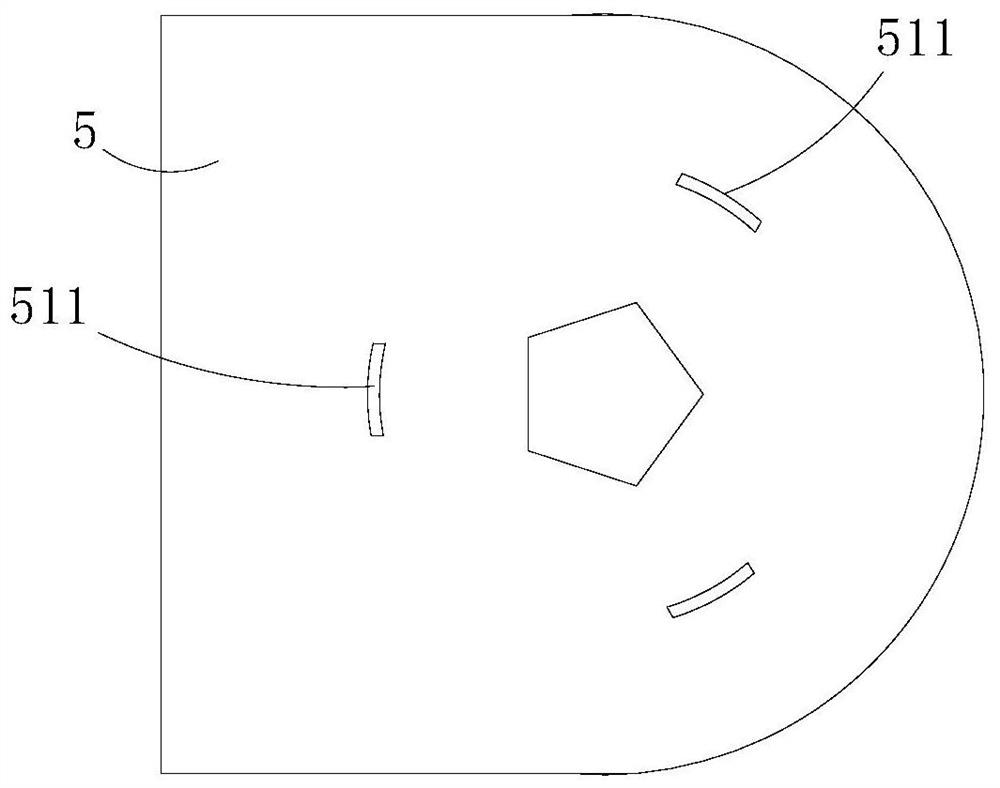

[0049] Such as Figure 1 to Figure 3 As shown, in some embodiments of the present invention, one side of each magnetic sheet 5 is provided with a foolproof portion 51, and the other side of each magnetic sheet 5 is provided with a foolproof slot 52, and each magnetic sheet 5 is provided with a foolproof groove 52. The fool-proof portions 51 of each piece 5 extend into the fool-proof slots 52 of adjacent magnetic pieces 5 . In this way, the relative rotation of two adjacent magnetic pieces 5 and the phenomenon of reverse installation can be avoided.

[0050] In some embodiments of the present invention, the fool-proof portion 51 includes a plurality of fool-proof protrusions 511 arranged at intervals along the circumference of the magnetic sheet 5 , and the fool-proof groove 52 includes A plurality of fool-proof grooves arranged at intervals in the circumferential direction.

[0051] In so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com