Anti-freezing gas leakage detection aerosol and preparation method thereof

An aerosol and gas technology, which is applied in the field of antifreeze gas leak detection aerosol and its preparation, can solve the problems of reducing the foaming and stabilization of gas leak detection agent, reducing the service life of pipelines, corrosion of aerosol tanks, etc., and achieving improvement Antifreeze effect, effect of eliminating defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

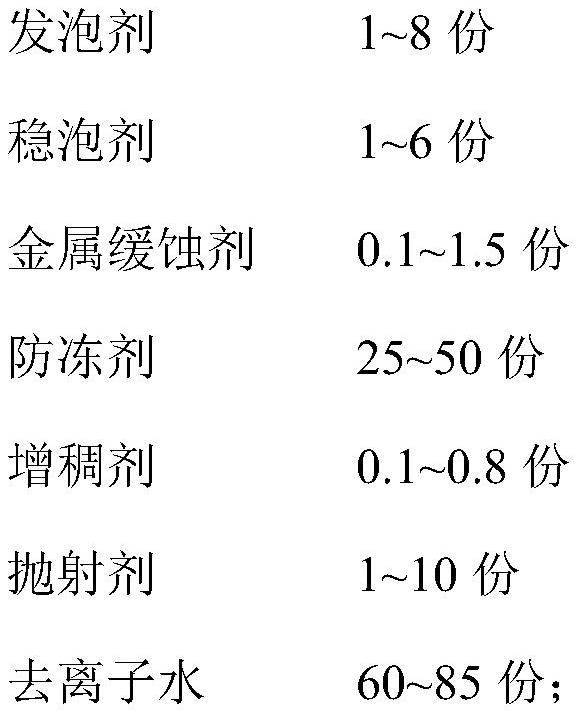

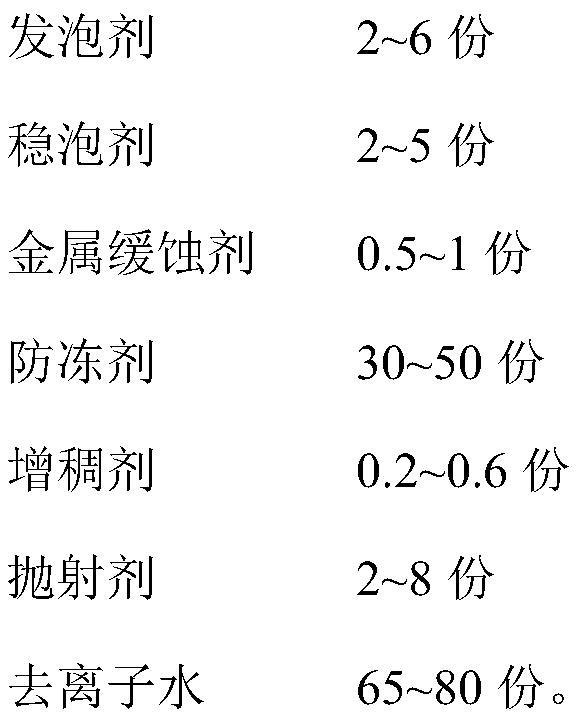

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of an antifreeze gas leak detection aerosol of this embodiment includes the following steps (the following dosages are all based on parts by weight):

[0032] (1) Mix propylene glycol and glycerin according to a weight ratio of 3:1 to make an antifreeze for use;

[0033] Put 70 parts of deionized water and 40 parts of antifreeze into the reaction kettle, turn on the stirring, and mix 3 parts of sodium myristoyl glutamate, 2 parts of N-alkyl glucamide, and carbopol under the stirring at 800r / min. 0.2 parts of mol, put into the reactor, continue to stir and disperse for 10 minutes.

[0034] (2) Under stirring at 1000r / min, 0.5 part of metal corrosion inhibitor is put into the reaction kettle, and after stirring and dispersing for 12 to 18 minutes, the base material is made; among them, the metal corrosion inhibitor is composed of sodium benzoate and pentahydrate Sodium metasilicate is a mixture uniformly mixed in a weight ratio of 3:2.

[0035] (3) After p...

Embodiment 2

[0038] The preparation method of an antifreeze gas leak detection aerosol of this embodiment includes the following steps (the following dosages are all based on parts by weight):

[0039] (1) Put 65 parts of deionized water and 30 parts of propylene glycol into the reaction kettle, turn on the stirring, and mix 6 parts of sodium myristoyl glutamate, 5 parts of N-alkylglucamide, and stirring at a speed of 750r / min. 0.6 part of carbomer was put into the reaction kettle and continued to stir and disperse for 12 min.

[0040] (2) Under stirring at 950r / min, 0.8 part of metal corrosion inhibitor was put into the reaction kettle, and after stirring and dispersing for 18 minutes, the base material was made; among them, the metal corrosion inhibitor was composed of benzotriazole and five A mixture of sodium metasilicate in water at a weight ratio of 2:1.

[0041] (3) After passing the base material through a 250-mesh filter, take 300g and put it into a 550ml aerosol can, and then use a sea...

Embodiment 3

[0044] The preparation method of an antifreeze gas leak detection aerosol of this embodiment includes the following steps (the following dosages are all based on parts by weight):

[0045] (1) Mix propylene glycol and glycerin according to a weight ratio of 2:3 to make an antifreeze for use;

[0046] Put 80 parts of deionized water and 50 parts of antifreeze into the reaction kettle, turn on the stirring, and mix 2 parts of sodium myristoyl glutamate, 4 parts of N-alkyl glucamide, and carbopol under the stirring at 850r / min. 0.4 parts per mol, put into the reaction kettle, continue to stir and disperse for 8 min.

[0047] (2) Under stirring at a speed of 1050r / min, put 1.5 parts of metal corrosion inhibitor into the reactor, continue to stir and disperse for 12 minutes, and then make the base material; among them, the metal corrosion inhibitor is composed of sodium benzoate and pentahydrate. A mixture of sodium and benzotriazole in a weight ratio of 1:2:2.

[0048] (3) After passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com