Modular structure for LNG receiving station

A modular and receiving station technology, applied in the field of LNG receiving stations, can solve the problems of construction work influence and constraints, long construction commissioning period, and poor device integration, so as to shorten the on-site construction period, reduce the overall investment of equipment, and improve the equipment quality. The effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

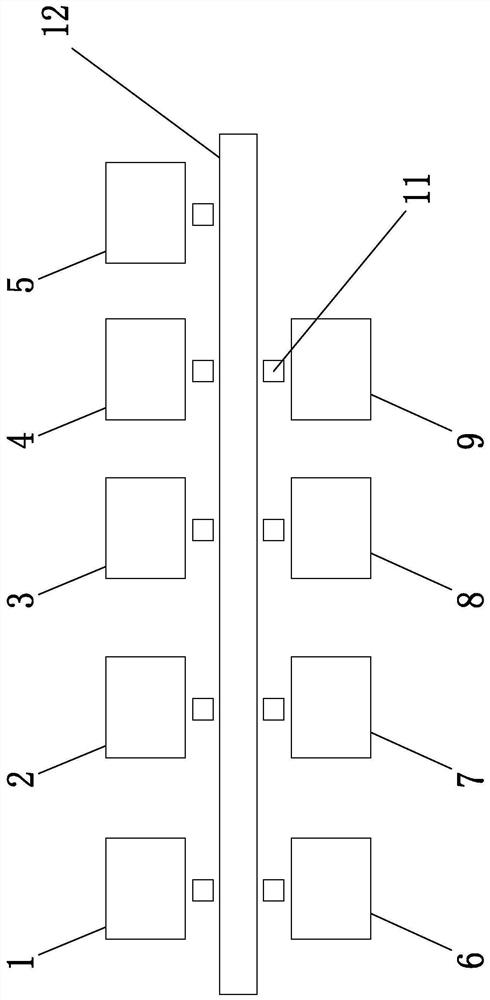

[0060] The present invention provides a modular structure of an LNG receiving station, which is structured as figure 1 As shown, there are loading and unloading ship module 1, storage tank module 2, high-pressure conveying module 3, recondenser module 4, BOG processing module 5, SCV module 6, ORV module 7, torch module 8, tank truck loading and unloading module 9 and main gallery Module 12, the loading and unloading module 1, the storage tank module 2, the high-pressure conveying module 3, the recondenser module 4, the BOG processing module 5, the SCV module 6, the ORV module 7, the torch module 8 and the tank truck loading and unloading module 9 (both Are process modules) each connected to the main gallery module 12 through a connecting pipe gallery module 11, wherein:

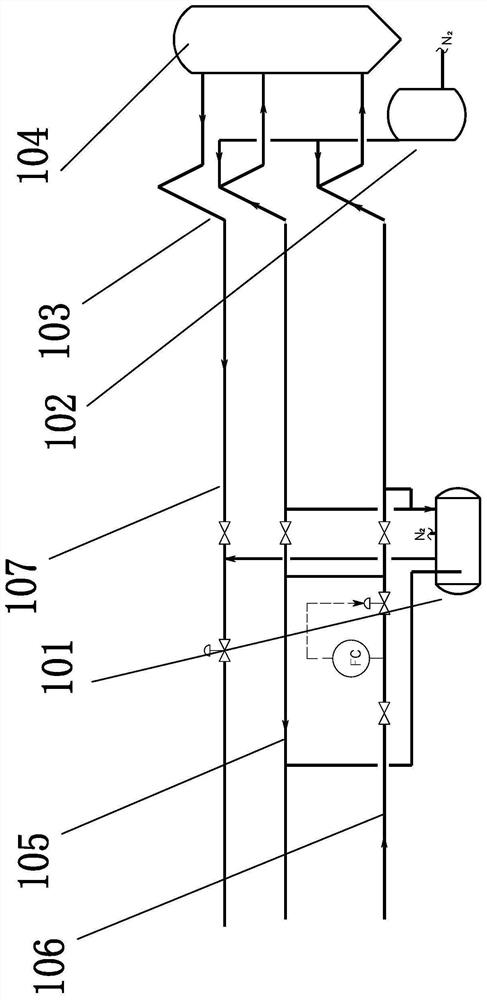

[0061] The main gallery module 12 has its function to integrate various process modules, such as Picture 11 As shown, it mainly includes a nitrogen pipeline 124, an instrument air pipeline 125, a factory air pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com