Boiler bottom through-wall expansion joint

An expansion joint and wall penetration technology, which is applied to expansion compensation devices for pipelines, thermal insulation, pipes, etc., can solve problems such as cracking, gradual collapse, and difficulty in thermal insulation of pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

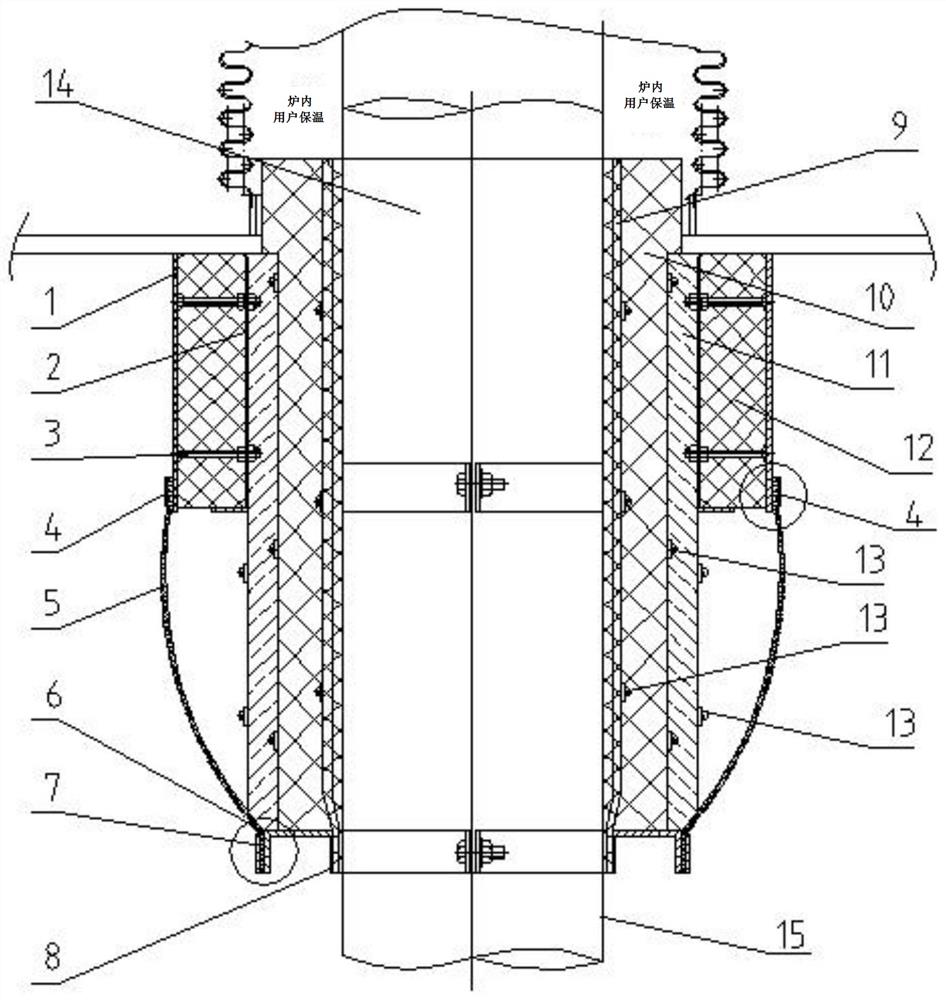

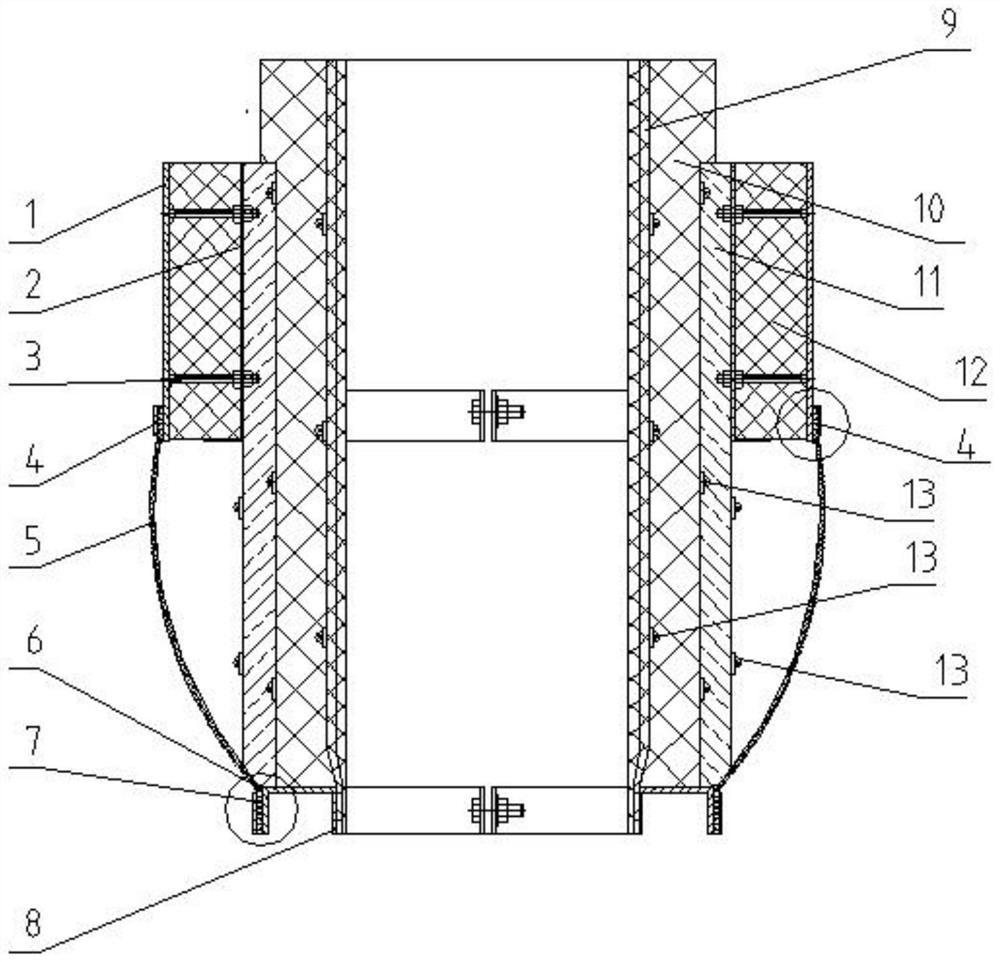

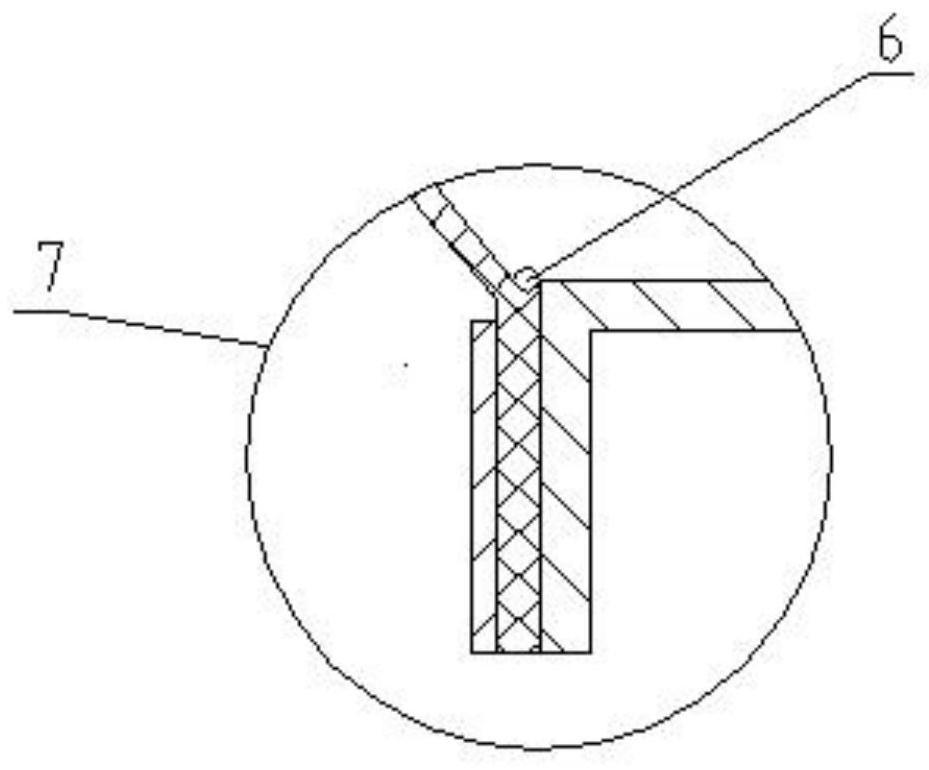

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0021] Such as figure 1 , figure 2 , image 3 As shown, a furnace bottom wall-penetrating expansion joint is used for the wall-penetrating connection of the waste heat boiler furnace bottom. The connecting pipe 1 and the thermal insulation liner 2 are filled with a fixed thermal insulation layer 4 12, and a number of studs 3 evenly distributed around the circumference are used. The connection is fixed in one piece, the strength is high, and the stress absorption is uniform, and it has a good heat preservation function.

[0022] The inner circle of the thermal insulation liner 2 is sequentially stacked with a fixed thermal insulation layer three 11, a fixed thermal insulation layer two 10 and a fixed thermal insulation layer one 9, and each adjacent fixed thermal insulation layer is fixed with a fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com