Processing method of nanofiber waterproof and moisture-permeable membrane with heat and humidity comfort

A technology of waterproof and moisture-permeable membranes and nanofibers, which is applied in the field of fiber membrane materials, can solve the problems of limiting material thermal and humidity comfort, poor deformation recovery performance, and poor air permeability, so as to improve water pressure resistance and moisture permeability flux, and meet thermal Effect of wet comfort requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

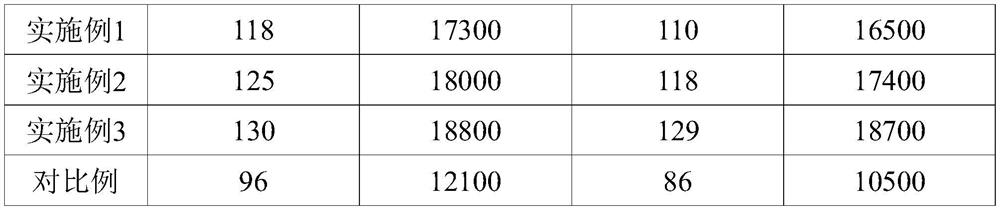

Embodiment 1

[0023] (1) Synthesis of hydrophobic polymer: Add 200mL of mixed solvent to the reaction kettle, preheat to 100°C, add 10g of ethyl isocyanate acrylate and 0.5g of dibenzoyl peroxide, heat to reflux, keep it warm for 4 hours, and depressurize The solvent is distilled off to obtain a hydrophobic polymer with an average degree of polymerization of 3800;

[0024] (2) Processing of nanofiber waterproof and moisture-permeable membrane: dissolving the prepared hydrophobic polymer in N,N-dimethylformamide to obtain a polymer solution with a mass concentration of 25%, and then electrospinning the polymer solution, When controlling spinning, the ambient temperature is 25°C, the relative humidity is 80%, the spinning voltage is set to 25kV, a stainless steel needle is used, the advancing speed of the syringe is 5mL / h, the fibers are collected on the grounded aluminum foil, and the receiving distance is 15cm. A nanofiber waterproof and moisture-permeable membrane is obtained.

[0025] Wh...

Embodiment 2

[0027] The difference between Example 2 and Example 1 is that the reaction time is adjusted to 5h during the synthesis of the hydrophobic polymer.

[0028] (1) Synthesis of hydrophobic polymer: Add 200mL of mixed solvent to the reaction kettle, preheat to 100°C, add 10g of ethyl isocyanate acrylate and 0.5g of dibenzoyl peroxide, heat to reflux, keep it warm for 5 hours, and depressurize The solvent is distilled off to obtain a hydrophobic polymer with an average degree of polymerization of 4300;

[0029] (2) Processing of nanofiber waterproof and moisture-permeable membrane: dissolving the prepared hydrophobic polymer in N,N-dimethylformamide to obtain a polymer solution with a mass concentration of 25%, and then electrospinning the polymer solution, When controlling spinning, the ambient temperature is 25°C, the relative humidity is 80%, the spinning voltage is set to 25kV, a stainless steel needle is used, the advancing speed of the syringe is 5mL / h, the fibers are collecte...

Embodiment 3

[0032] The difference between embodiment 3 and embodiment 2 is that the variable temperature treatment is added.

[0033] (1) Synthesis of hydrophobic polymer: Add 200mL of mixed solvent to the reaction kettle, preheat to 100°C, add 10g of ethyl isocyanate acrylate and 0.5g of dibenzoyl peroxide, heat to reflux, keep it warm for 5 hours, and depressurize The solvent is distilled off to obtain a hydrophobic polymer with an average degree of polymerization of 4300;

[0034] (2) Processing of nanofiber waterproof and moisture-permeable membrane: dissolving the prepared hydrophobic polymer in N,N-dimethylformamide to obtain a polymer solution with a mass concentration of 25%, and then electrospinning the polymer solution, When controlling spinning, the ambient temperature is 25°C, the relative humidity is 80%, the spinning voltage is set to 25kV, a stainless steel needle is used, the advancing speed of the syringe is 5mL / h, the fibers are collected on the grounded aluminum foil, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com