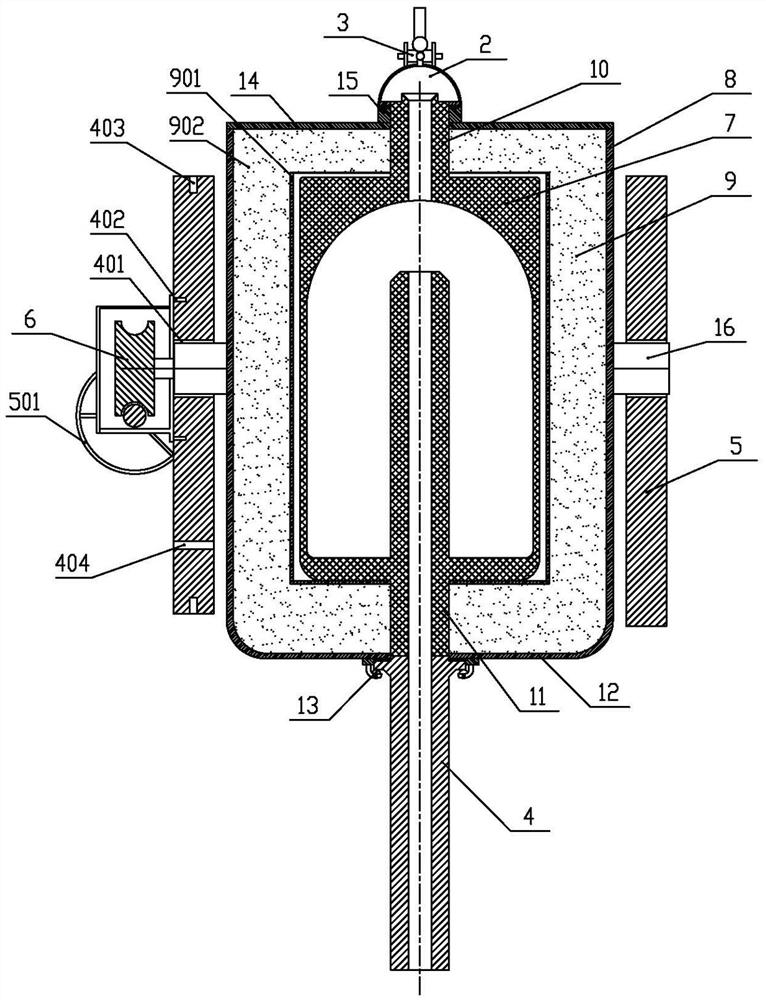

Vertical ladle for vacuum suction and injection of liquid rare earth metal

A rare earth metal, vacuum imbibition technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of complexity, reduced output of electrolyzers, large equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

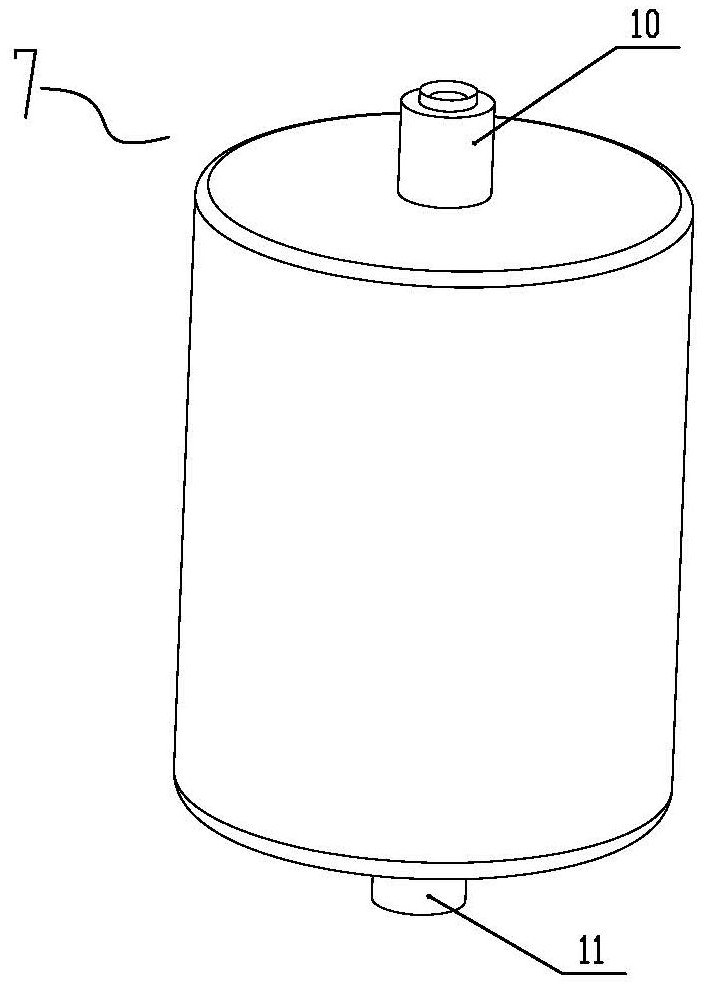

Embodiment 1

[0036] Embodiment 1: When the present invention is used in the production of liquid rare earth metals by electrolysis, the components mentioned above are prepared before operation and connected and assembled, and the arm frame of the external plug-in vehicle is connected and fixed with the package body connector 5 , fix the externally equipped vacuum pump with an air pumping capacity of 0.5 liters per second on the enclosure connector 5, and connect the externally equipped vacuum hose to the vacuum line interface 311, and the externally equipped compressed air source tube and the booster Air interface 309 is connected well, and the total height of the present invention is 1780mm, and the inner diameter of liquid suction pipe 4 is 30mm, and the inner cavity volume of liquid storage liner 7 is 65 liters, and the total height of inner cavity is 0.6 meter. Cover the liquid outlet sealing cap 2, and press the hollow swing rod 303 with wedge pin 305 to form a seal between the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com