A high-strength and high-toughness nickel-based superalloy foil and its preparation method

A nickel-based superalloy, high-strength and high-toughness technology, applied to nickel-based superalloy foils, high-strength and high-toughness nickel-based superalloy foils and their preparation fields, can solve problems such as inapplicability, achieve low density, improve high-temperature mechanical properties performance, the effect of improving the anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

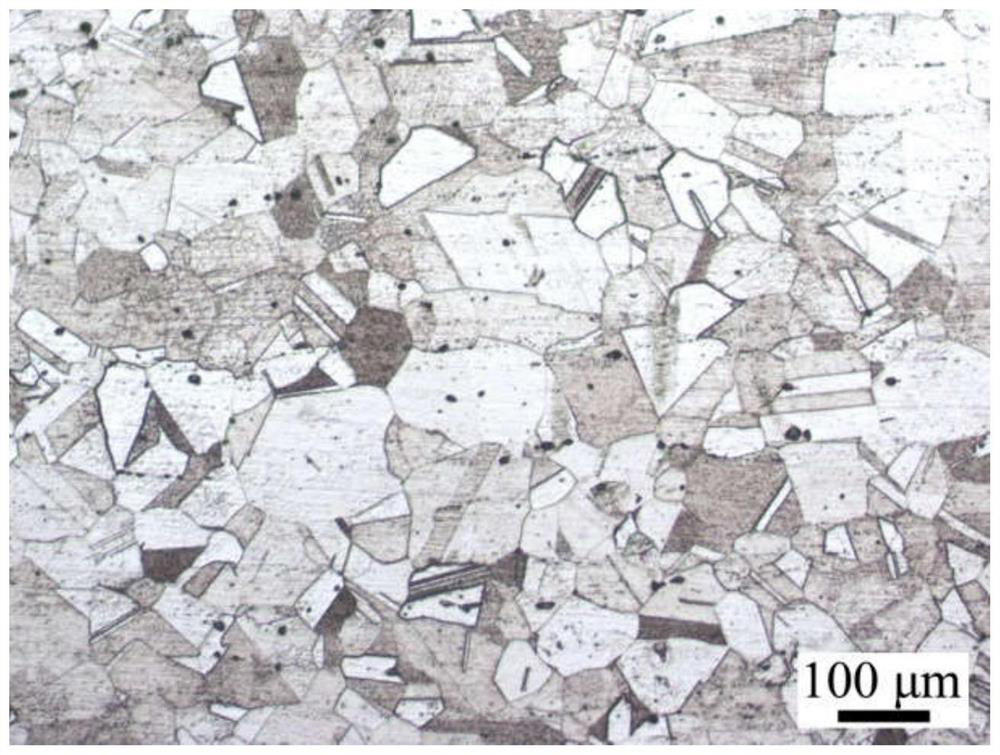

Image

Examples

Embodiment 1

[0048] According to the ingredients shown in alloys 1-2 in Table 1, weigh C, Cr, Al, Fe, Y, Ti, Mn, Ce, Si, B raw materials, the raw material Cr is a block with a purity of 99.99%, and the raw material Fe It is in the form of a block with a purity of 99.8%, and the raw material Ni is in the form of a block with a purity of 99.99%. Put the raw materials C, Cr, Fe and Ni into the crucible of the vacuum induction melting furnace, and then vacuumize it. When the vacuum degree reaches 2Pa, heat it with a low power of 100KW to discharge the gas attached to the charge; when the vacuum degree reaches 0.5Pa, Use 280KW power to melt the material until the furnace material is completely melted; after the furnace material is completely melted, raise the temperature to 1590°C, and after 45 minutes of high-temperature refining, power off the conjunctiva; then use 280KW high power to heat up and break the membrane. Ti, C, B, Ce, and evenly stirred; Alloy secondary refining: continue to heat ...

Embodiment 2

[0050] According to the ingredients shown in the alloys 3 to 4 in Table 1, weigh C, Cr, Al, Fe, Y, Ti, Mn, Ce, Si, B raw materials, the raw material Cr is a block with a purity of 99.992%, and the raw material Fe It is in the form of a block with a purity of 99.85%, and the raw material Ni is in the form of a block with a purity of 99.992%. Put the raw materials C, Cr, Fe and Ni into the crucible of the vacuum induction melting furnace, and then vacuumize it. When the vacuum degree reaches 1Pa, heat with a low power of 80KW to discharge the gas attached to the charge; when the vacuum degree reaches 0.4Pa, Use 285KW power to melt the material until the furnace material is completely melted; after the furnace material is completely melted, raise the temperature to 1600°C, and after 40 minutes of high-temperature refining, power off the conjunctiva; then use 285KW high power to heat up and break the membrane. Ti, C, B, Ce, and evenly stirred; alloy secondary refining: continue to...

Embodiment 3

[0052] According to the ingredients shown in alloys 5-6 in Table 1, weigh C, Cr, Al, Fe, Y, Ti, Mn, Ce, Si, B raw materials, the raw material Cr is a block with a purity of 99.995%, and the raw material Fe It is a block with a purity of 99.9%, and the raw material Ni is a block with a purity of 99.992%. Put the raw materials C, Cr, Fe and Ni into the crucible of the vacuum induction melting furnace, and then vacuumize it. When the vacuum degree reaches 1.5Pa, heat it with a low power of 90KW to discharge the gas attached to the charge; when the vacuum degree reaches 0.3Pa , with a power of 290KW, until the charge is completely melted; after the charge is completely melted, the temperature is raised to 1610°C, and the high-temperature refining is performed for 45 minutes. , Ti, C, B, Ce, and evenly stirred; secondary refining of the alloy: continue to heat up, refining at 1590 °C for 2 minutes; adjust the furnace temperature to 1510 °C, and pour, directly pouring into a size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com