A kind of immunomodulatory active peptide and its preparation method and application

A technology of immunomodulatory activity and active peptides, which is applied in the field of immunomodulatory active peptides and their preparation, can solve the problem of fewer active peptide products, achieve the effects of increasing product added value, good immune regulatory activity, and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

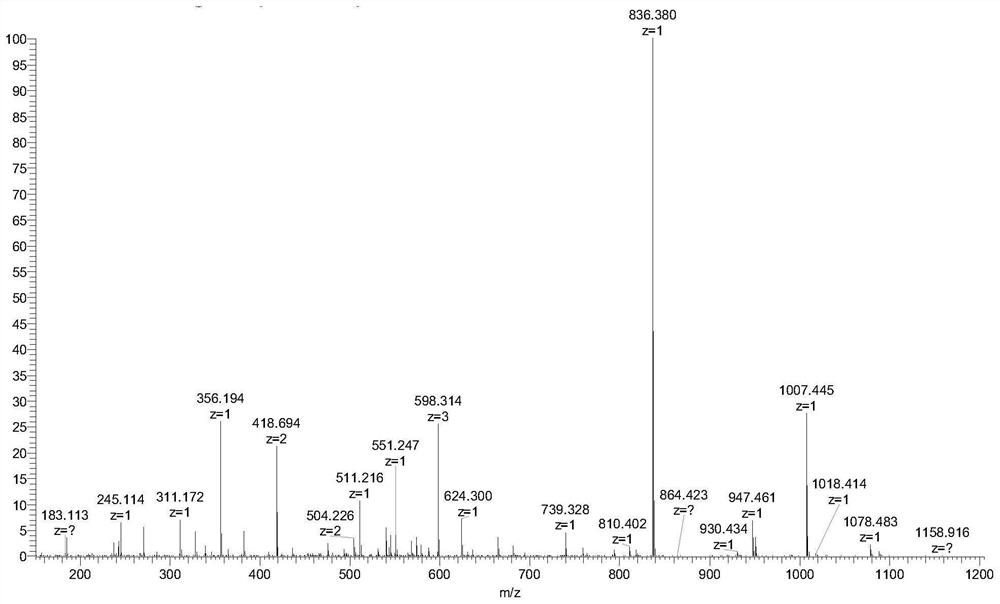

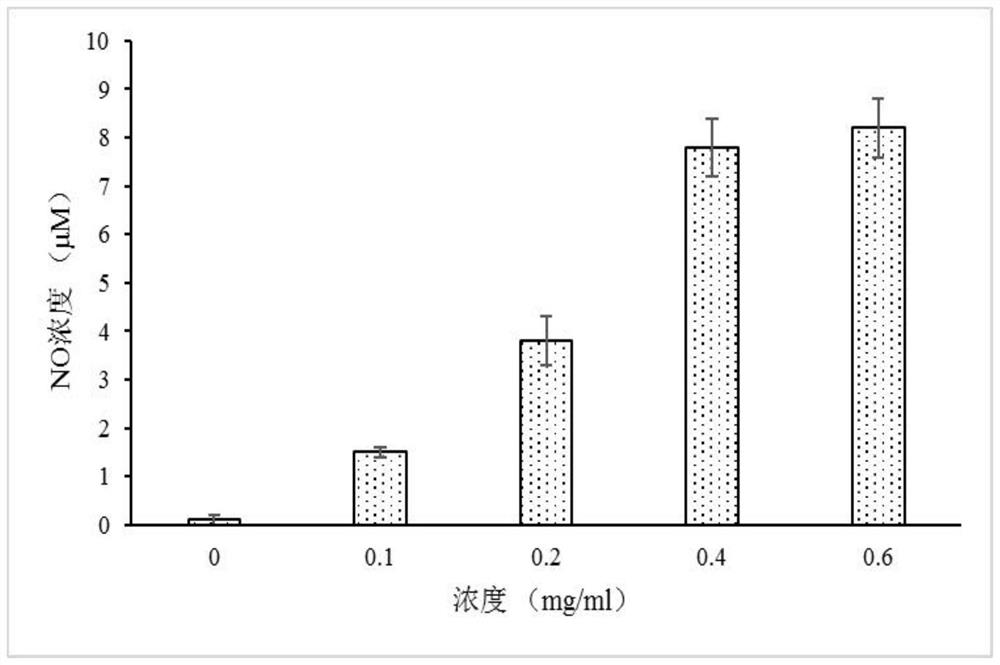

[0021] Example 1: Preparation, separation and structural identification of immunomodulatory active peptides

[0022] 1. Preparation and separation of immunomodulatory active peptides

[0023] 1) Material selection: choose soybean protein isolate.

[0024] 2) Preparation: Add 10 times the mass of soybean protein isolate in water, then stir to disperse.

[0025] 3) Enzymatic hydrolysis: add 0.5% alkaline protease according to the quality of soybean protein isolate, pH 8.5, temperature 50°C, enzymolysis for 3 hours, then add 0.5% protease SmPA, pH 7.0, temperature 50°C, enzymolysis 3 hours. Raise the temperature to 90°C and keep for 20 minutes to inactivate the enzyme, centrifuge to obtain the supernatant of the protein hydrolyzate, filter it with an ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons, collect the permeate and spray dry to obtain the soybean protein hydrolyzate.

[0026] 4) Column purification: the soybean protein hydrolyzate is purified b...

Embodiment 2

[0037] 1. Preparation and separation of immunomodulatory active peptides

[0038] 1) Material selection: choose soybean protein isolate.

[0039] 2) Preparation: Add water with 5 times the mass of soybean protein isolate, then stir to disperse.

[0040] 3) Enzymatic hydrolysis: Add 0.1% alkaline protease according to the quality of soybean protein isolate, pH 7.5, temperature 30°C, enzymolysis for 1 hour, then add 0.1% protease SmPA, pH 6.0, temperature 40°C, enzymolysis 1 hour. Raise the temperature to 90°C for 20 minutes to inactivate the enzyme, centrifuge to obtain the supernatant of the protein hydrolyzate, filter it with an ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons, and collect the permeate and spray dry it.

[0041] 4) Column purification: the soybean protein hydrolyzate is purified by a C18 reverse-phase chromatographic column (15×460 mm), and gradient eluted with water and ethanol aqueous solution, specifically, the volume fraction of ...

Embodiment 3

[0044] 1. Preparation and separation of immunomodulatory active peptides

[0045] 1) Material selection: choose soybean protein isolate;

[0046] 2) Preparation: Add water with 20 times the mass of soybean protein isolate, then stir to disperse.

[0047] 3) Enzymatic hydrolysis: add 1.0% alkaline protease according to the quality of soybean protein isolate, pH 8.5, temperature 50°C, enzymolysis for 5 hours, then add 1.0% self-made protease SmPA, pH 7.0, temperature 50°C, enzyme solution for 5 hours. Raise the temperature to 90°C for 20 minutes to inactivate the enzyme, centrifuge to obtain the supernatant of the protein hydrolyzate, filter it with an ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons, collect the permeate and spray dry to obtain the soybean protein hydrolyzate.

[0048] 4) Column purification: the soybean protein hydrolyzate is purified by a C18 reverse-phase chromatographic column (15×460 mm), and gradient eluted with water and ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com