Grouting material for large bridge support and preparation method thereof

A bridge bearing and grouting material technology, which is applied in the field of building materials, can solve the problems of poor freeze-thaw durability and slow early strength development, and achieve the effects of reducing shrinkage and thermal expansion coefficient, improving early strength, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

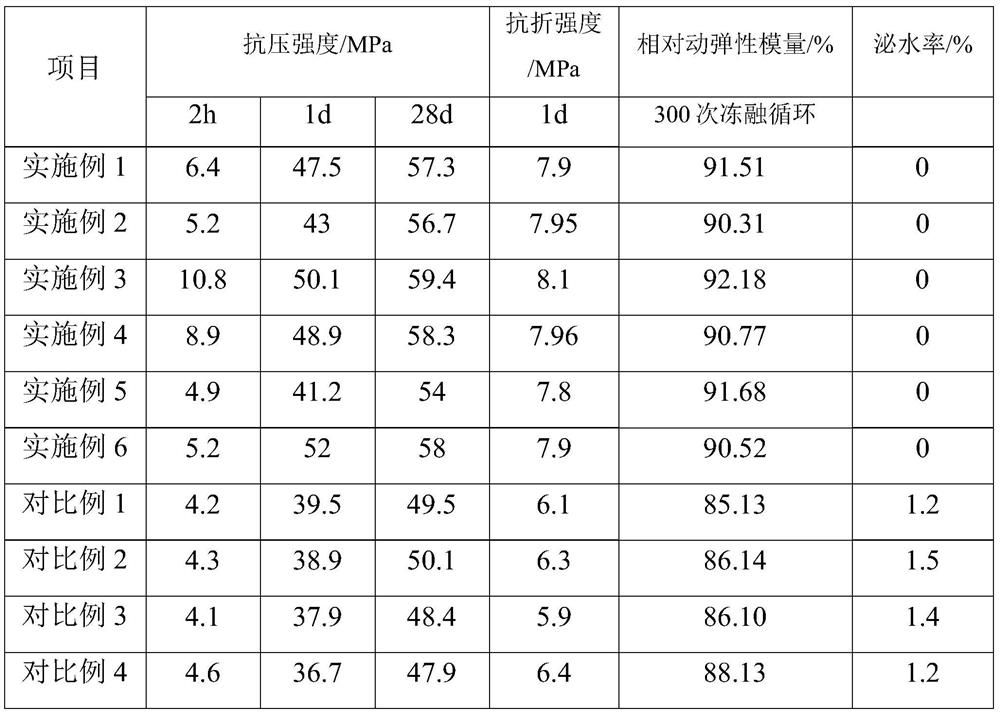

Examples

Embodiment 1

[0030] A grouting material for large bridge supports, including the following raw material components in parts by mass: 30 parts of 72.5 grade rapid hardening sulfoaluminate cement; 30 parts of stone; 28 parts of natural sand; 4 parts of grade II fly ash 1.2 parts of polyacrylate-polyurethane copolymer emulsion (solid content is 50%); 1.5 parts of dihydrate gypsum; 0.5 part of hardening agent; 0.1 part of retarder; 0.3 parts of water and 9.6 parts of water,

[0031] Wherein, the hardening accelerator is a mixture of calcium formate and sodium nitrite with a mass ratio of 1:1.2; the retarder is a mixture of sodium gluconate and boric acid with a mass ratio of 1:3.8;

[0032]The solid content of the polyacrylate-polyurethane copolymer emulsion is 50%, and the molar ratio of the polyurethane part to the polyacrylate part in the polyacrylate-polyurethane copolymer segment is 20:80. The specific preparation method is as follows:

[0033] S1: Polypropylene glycol 600 and castor oil...

Embodiment 2

[0039] A grouting material for large bridge supports, including the following raw material components in parts by mass: 28 parts of 72.5 grade rapid hardening sulfoaluminate cement; 38 parts of stone; 30 parts of natural sand; 3 parts of grade II fly ash 1.7 parts of polyacrylate-polyurethane copolymer emulsion (solid content is 40%); 2 parts of dihydrate gypsum; 0.5 part of hardener; 0.2 part of retarder; 0.2 parts of water and 9.5 parts of water,

[0040] Wherein, the hardening accelerator is a mixture of calcium formate and sodium nitrite with a mass ratio of 1:0.8; the retarder is a mixture of sodium gluconate and boric acid with a mass ratio of 1:3.2;

[0041] The solid content of the polyacrylate-polyurethane copolymer emulsion is 40%, and the molar ratio of the polyurethane part to the polyacrylate part in the polyacrylate-polyurethane copolymer segment is 10:90. The specific preparation method is as follows:

[0042] S1: Polypropylene glycol 600 and castor oil with a ...

Embodiment 3

[0048] A grouting material for large bridge supports, including the following raw material components in parts by mass: 26 parts of 72.5 grade rapid hardening sulfoaluminate cement; 32 parts of stone; 28 parts of natural sand; 6 parts of grade II fly ash 0.5 part of polyacrylate-polyurethane copolymer emulsion (solid content is 30%); 1 part of dihydrate gypsum; 0.8 part of hardener; 0.08 part of retarder; 0.4 parts of water and 9.4 parts of water,

[0049] Wherein, the hardening accelerator is a mixture of calcium formate and sodium nitrite with a mass ratio of 1:1; the retarder is a mixture of sodium gluconate and boric acid with a mass ratio of 1:3.5;

[0050] The solid content of the polyacrylate-polyurethane copolymer emulsion is 30%, and the molar ratio of the polyurethane part to the polyacrylate part in the polyacrylate-polyurethane copolymer segment is 15:85. The specific preparation method is as follows:

[0051] S1: Polypropylene glycol 600 and castor oil with a mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com