Method for preparing foamed wall material from municipal sludge

A technology of wall materials and municipal sludge, applied in the direction of biological sludge treatment, application, household appliances, etc., can solve the problems that affect the mechanical strength and service life of building materials, foul smell, and reduce user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

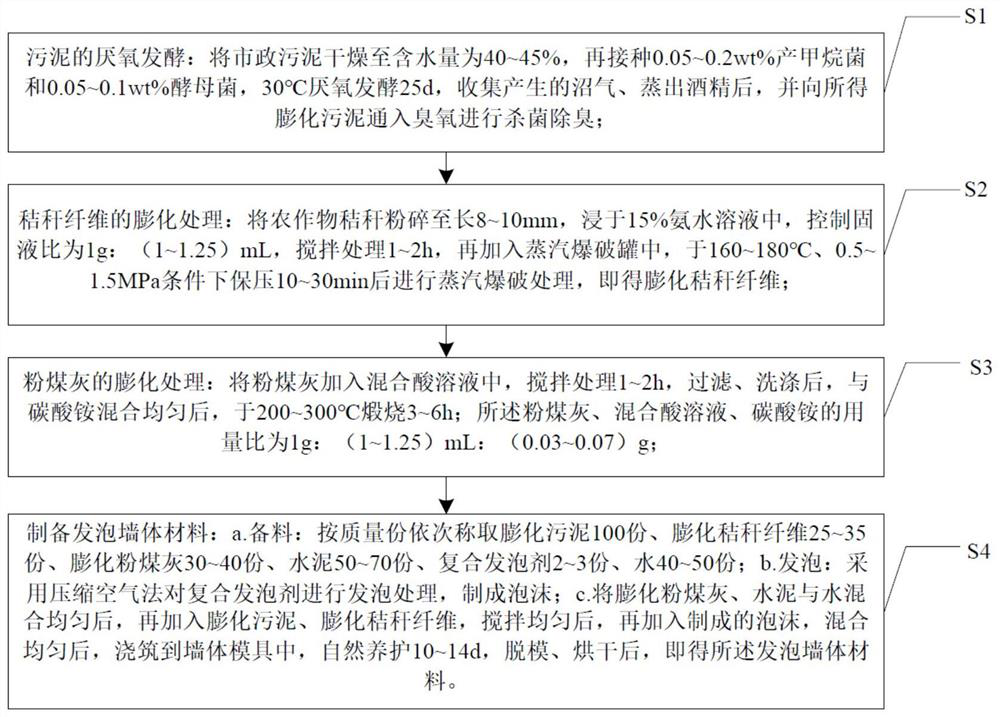

Method used

Image

Examples

Embodiment 1

[0030] A kind of method utilizing municipal sludge to prepare foam wall material, comprises the following steps:

[0031] S1: Anaerobic fermentation of sludge: the municipal sludge is dried to a water content of 40%, and then inoculated with 0.1wt% Methanobacterium formici (preservation number is DSM-No.1535) and 0.05wt% Saccharomyces cerevisiae (preservation number is CCTCC No: M2011290), anaerobic fermentation at 30°C for 25 days, after collecting the generated biogas and distilling off the alcohol, inject ozone into the obtained expanded sludge at a flow rate of 2L / min for 1 hour to sterilize and deodorize;

[0032] S2: Puffing treatment of straw fiber: crush the rape straw to 8mm in length, soak it in 15% ammonia solution, control the solid-liquid ratio to 1g:1mL, stir for 1h, then put it into a steam explosion tank, at 160°C, 0.5MPa After holding the pressure for 10 minutes under the same conditions, steam explosion treatment is carried out to obtain puffed straw fibers; ...

Embodiment 2

[0040] A kind of method utilizing municipal sludge to prepare foam wall material, comprises the following steps:

[0041] S1: Anaerobic fermentation of sludge: the municipal sludge is dried to a water content of 45%, and then inoculated with 0.15wt% Methanobacterium formici (preservation number is DSM-No.1535) and 0.075wt% Saccharomyces cerevisiae (preservation number is CCTCC No: M2011290), anaerobic fermentation at 30°C for 25 days, after collecting the generated biogas and distilling off the alcohol, inject ozone into the obtained expanded sludge at a flow rate of 4L / min for 1 hour to sterilize and deodorize;

[0042] S2: Puffing treatment of straw fiber: crush wheat straw to a length of 10mm, soak in 15% ammonia solution, control the solid-liquid ratio to 1g:1.25mL, stir for 2h, then add it to a steam explosion tank, and heat it at 170°C and 1MPa After keeping the pressure for 20 minutes under the same conditions, steam explosion treatment is carried out to obtain puffed s...

Embodiment 3

[0050] A kind of method utilizing municipal sludge to prepare foam wall material, comprises the following steps:

[0051] S1: Anaerobic fermentation of sludge: the municipal sludge is dried to a water content of 45%, and then inoculated with 0.2wt% Methanobacterium formici (preservation number is DSM-No.1535) and 0.1wt% Saccharomyces cerevisiae (preservation number is CCTCC No: M2011290), anaerobic fermentation at 30°C for 25 days, after collecting the generated biogas and distilling the alcohol, and passing ozone into the obtained expanded sludge at a flow rate of 6L / min for 2 hours to sterilize and deodorize;

[0052] S2: Puffing treatment of straw fiber: crush wheat straw to a length of 10mm, soak it in 15% ammonia solution, control the solid-liquid ratio to 1g:1.25mL, stir for 2h, then put it into a steam explosion tank, and heat it at 180°C, 1.5 Under the condition of MPa, pressurize for 30 minutes and then carry out steam explosion treatment to obtain puffed straw fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com