Customized cabinet door plank edge banding processing method

A processing method and door panel technology, applied in the field of furniture processing, can solve the problems of low utilization rate of seals, overflow of glue over the edge of the door panel, waste of seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

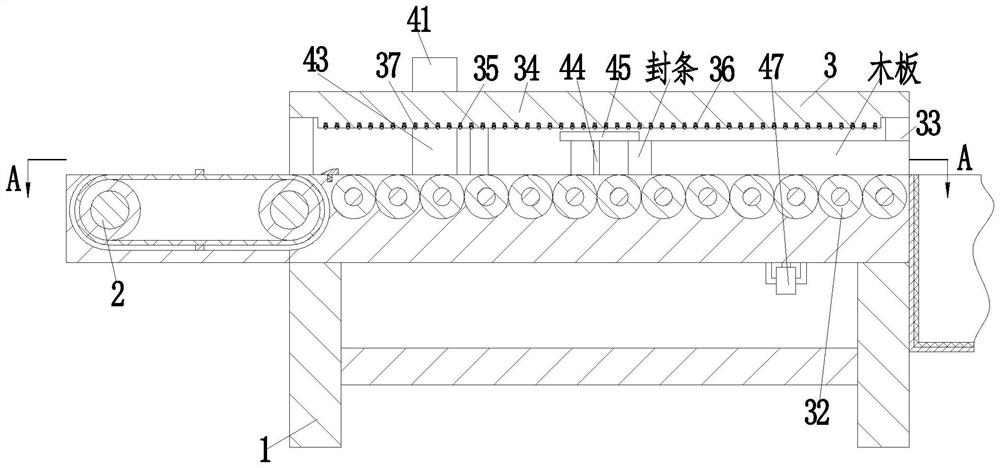

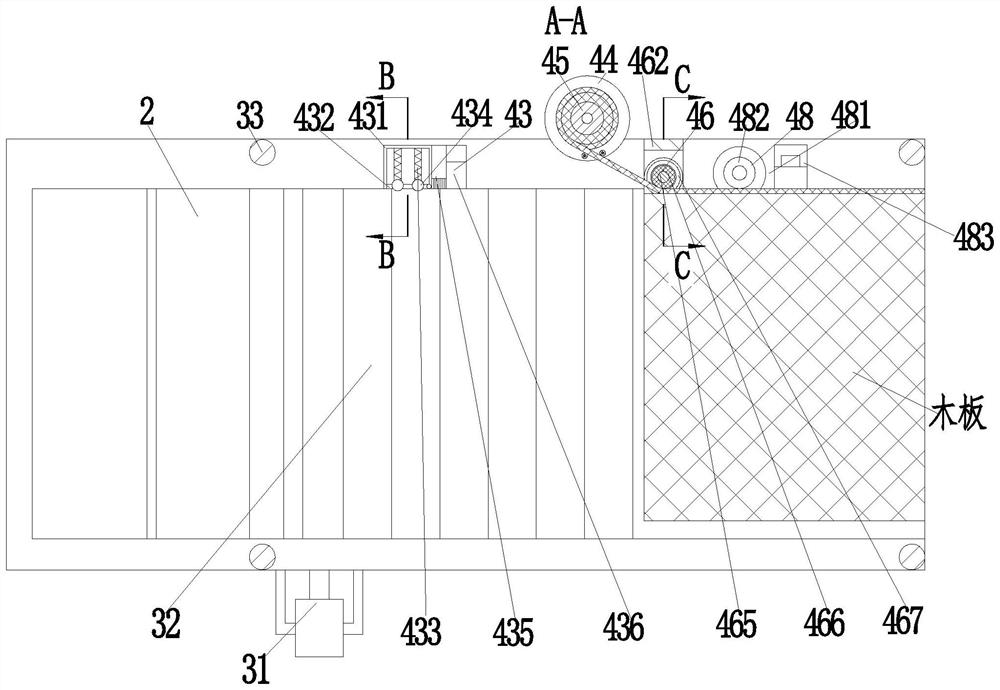

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

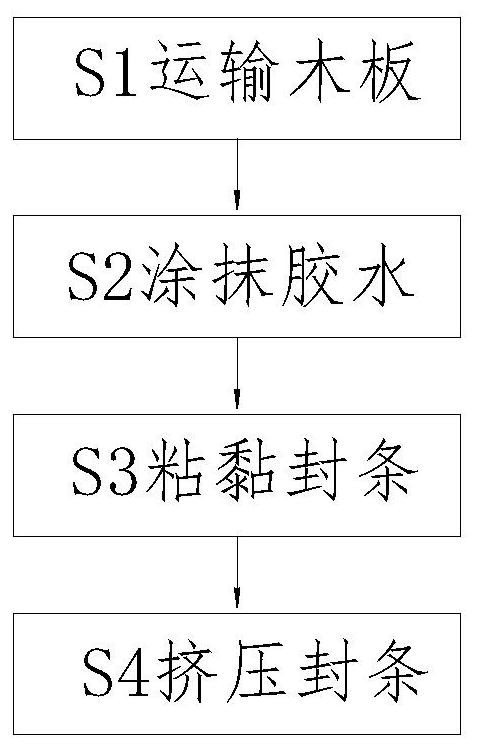

[0038] A custom cabinet door panel edge banding processing method, which uses a custom cabinet door panel edge banding processing equipment, the custom cabinet door panel edge banding processing equipment includes a workbench 1, a belt conveyor 2, a transport device 3 and an edge banding device 4 , the specific method of processing the edge banding of cabinet door panels by using the above-mentioned customized cabinet door panel edge banding processing equipment is as follows:

[0039] S1. Transport wooden boards: place the wooden boards on the equipment, and align the wooden boards through the equipment;

[0040] S2. Apply glue: Apply glue to the front end of the plank transported to the right, and brush the glue on the plank at the same time to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com