Conveying type electroplating machine

A conveying and mechanical technology, applied in the direction of abrasive jetting machine tools, used abrasive processing devices, explosion generating devices, etc., can solve the problem that abrasive particles cannot be ejected from the nozzle, affect metal sandblasting treatment, and unevenness of metal surface question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

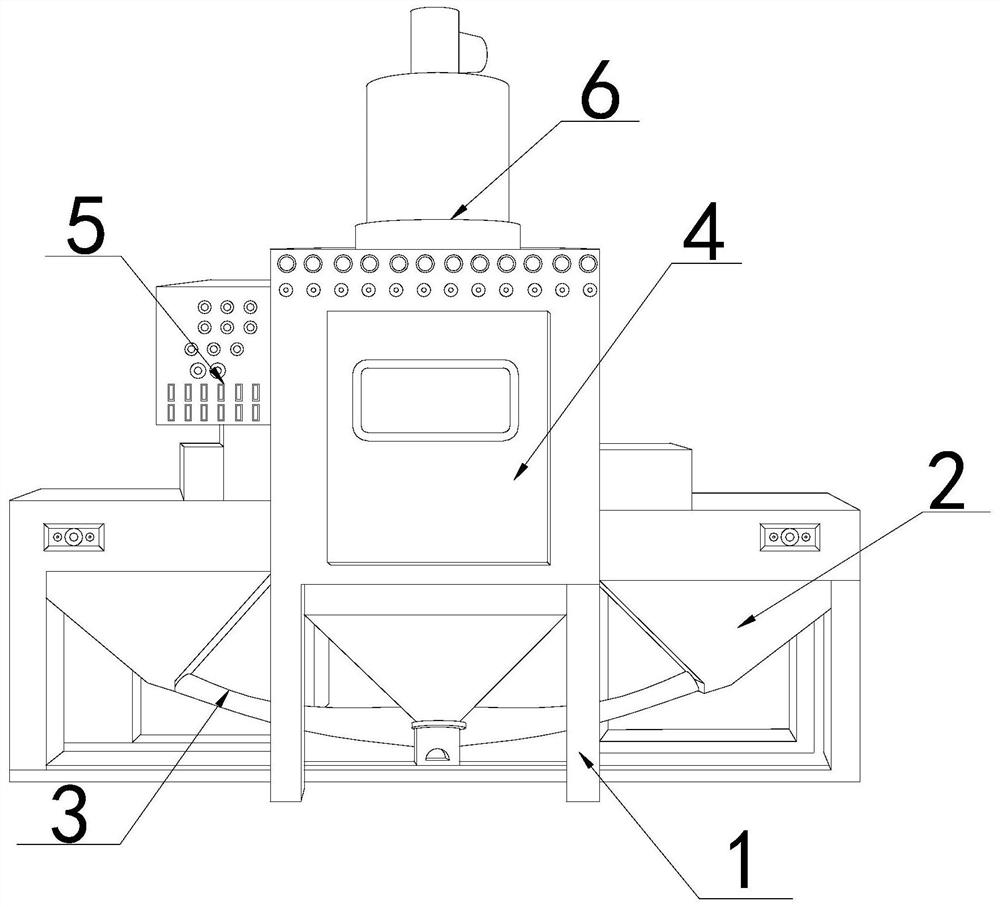

[0028] The present invention provides a conveying type electroplating machine, the structure of which includes a bracket 1, a trough 2, a material delivery pipe 3, a workbench 4, a console 5, and an air pump 6, the trough 2 is installed inside the bracket 1, and the The workbench 4 is fixed on the top of the support 1 , the console 5 is fixed on the left side of the workbench 4 , the air pump 6 is installed on the top of the workbench 4 , and the feed tank 2 is connected with the workbench 4 through the feeding pipe 3 .

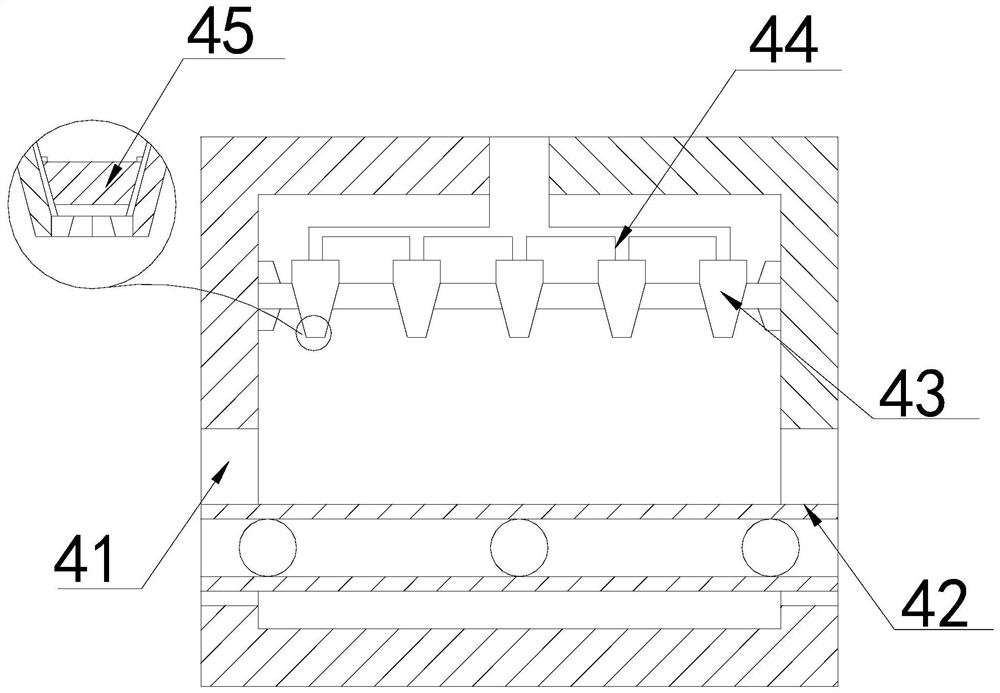

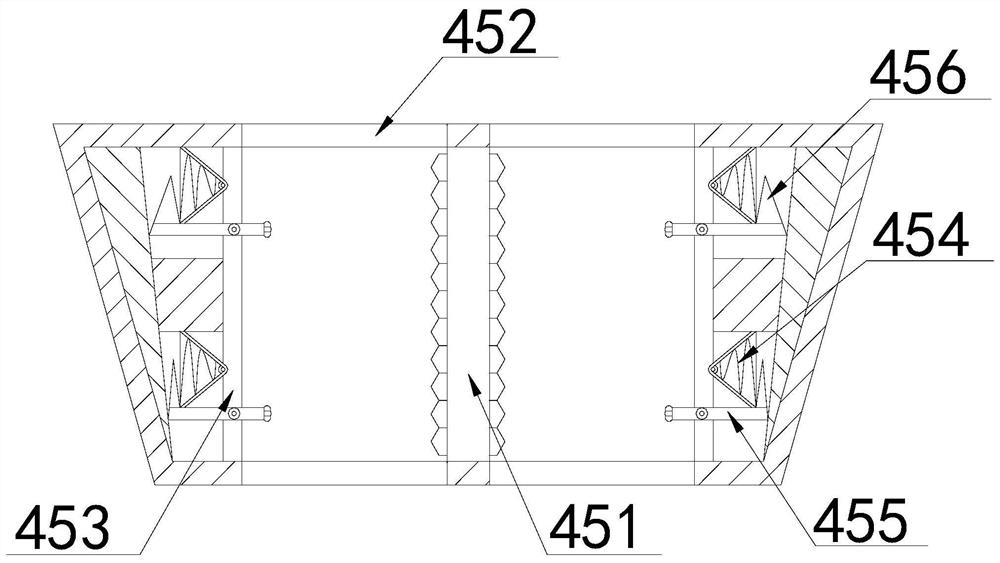

[0029] The workbench 4 is provided with an opening 41, a conveyor belt 42, a nozzle 43, a connecting pipe 44, and a block 45. The openings 41 respectively pass through both sides of the middle and lower part of the workbench 4, and the conveyor belt 42 passes through the opening 41 and is arranged on the workbench. 4, the nozzle 43 is installed inside the workbench 4, the connecting pipe 44 is connect...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 8 Shown:

[0037] Wherein, the side groove a1 is provided with a slide rail a11, a clamping block a12, a slider a13, and a brush block a14. The sliding rail a11 is movably matched, and the brush block a14 is installed on the surface of the clamping block a12. The brush block a14 is an arc-shaped surface, which increases the contact with the contact head a6 and accelerates the removal of abrasive powder on the surface of the contact head a6.

[0038] Wherein, the brush block a14 is provided with a reset block b1, a connecting block b2, and teeth b3, the connecting block b2 is connected with the inner wall of the brush block a14 through the reset block b1, and the teeth b3 are fixed on the surface of the connecting block b2, The teeth b3 are made of metal brushes with relatively high hardness, which can more fully remove the powder with high hardness.

[0039] Wherein, the connection block b2 is provided with an airbag b21, a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com