A high-efficiency lime powder spraying machine

A technology of lime powder and dusting machine, applied in electrostatic, electrical components, grain processing and other directions, can solve the problems of personal injury of staff, blocked pipelines, affecting the grinding efficiency of hammer mill of powder blower, etc., to improve the grinding effect, Prevent reverse flow and overcome the effect of hammer mill grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

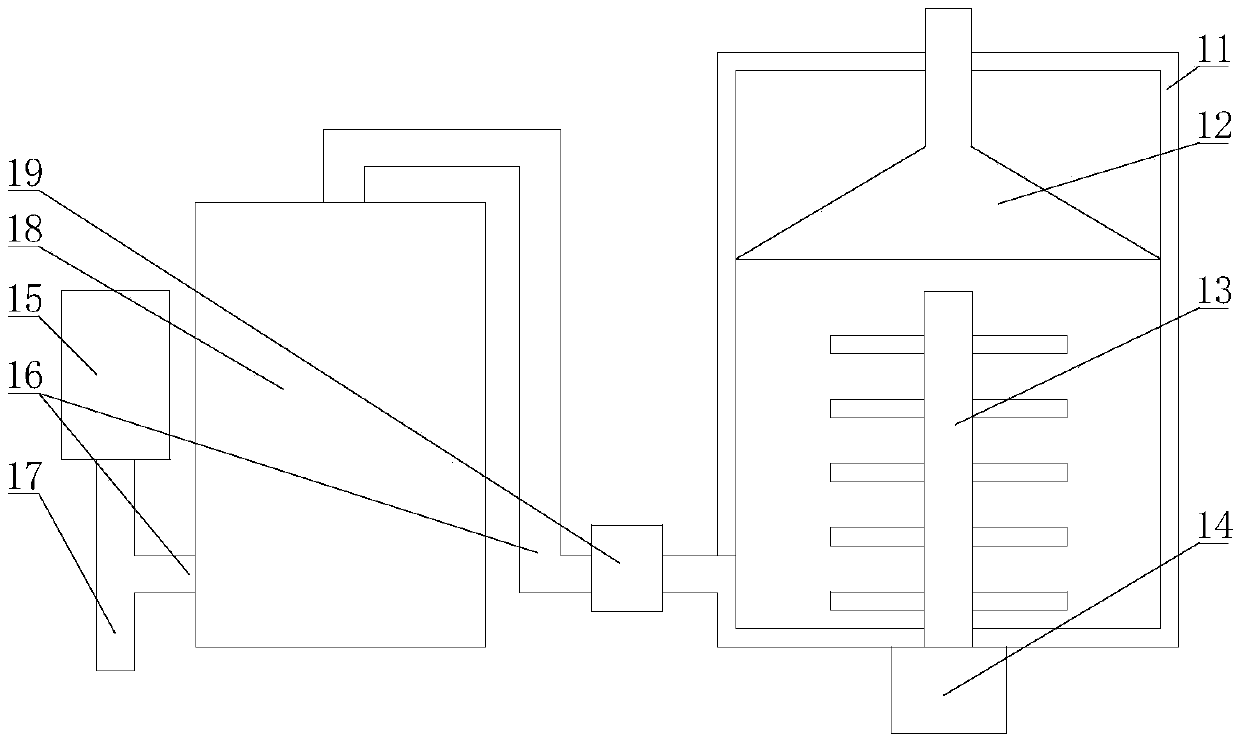

[0038] A high-efficiency lime powder spraying machine includes a material barrel 11, and a feed regulating bucket 12 is arranged in the inner cavity of the material barrel 11, and the feeding port of the feed regulating bucket 12 passes through the top of the material barrel 11. A driving motor 14 is connected to the bottom of the material barrel 11 , and a vibrating stirring device 13 is arranged in the material barrel 11 , and the vibrating stirring device 13 is connected to the driving motor 14 . One end of the bottom of the material barrel 11 is connected with a discharge pipe 16, and one end of the discharge pipe 16 is connected with a discharge pipe 17, and the middle part of the discharge pipe 17 is connected with the discharge pipe 16, and the other end of the discharge pipe 17 is connected with a The first fan 15. In addition, between the material barrel 11 and the discharge pipe 17, a re-grinding device 18 is also provided to prevent the reverse flow of the high-spee...

Embodiment 2

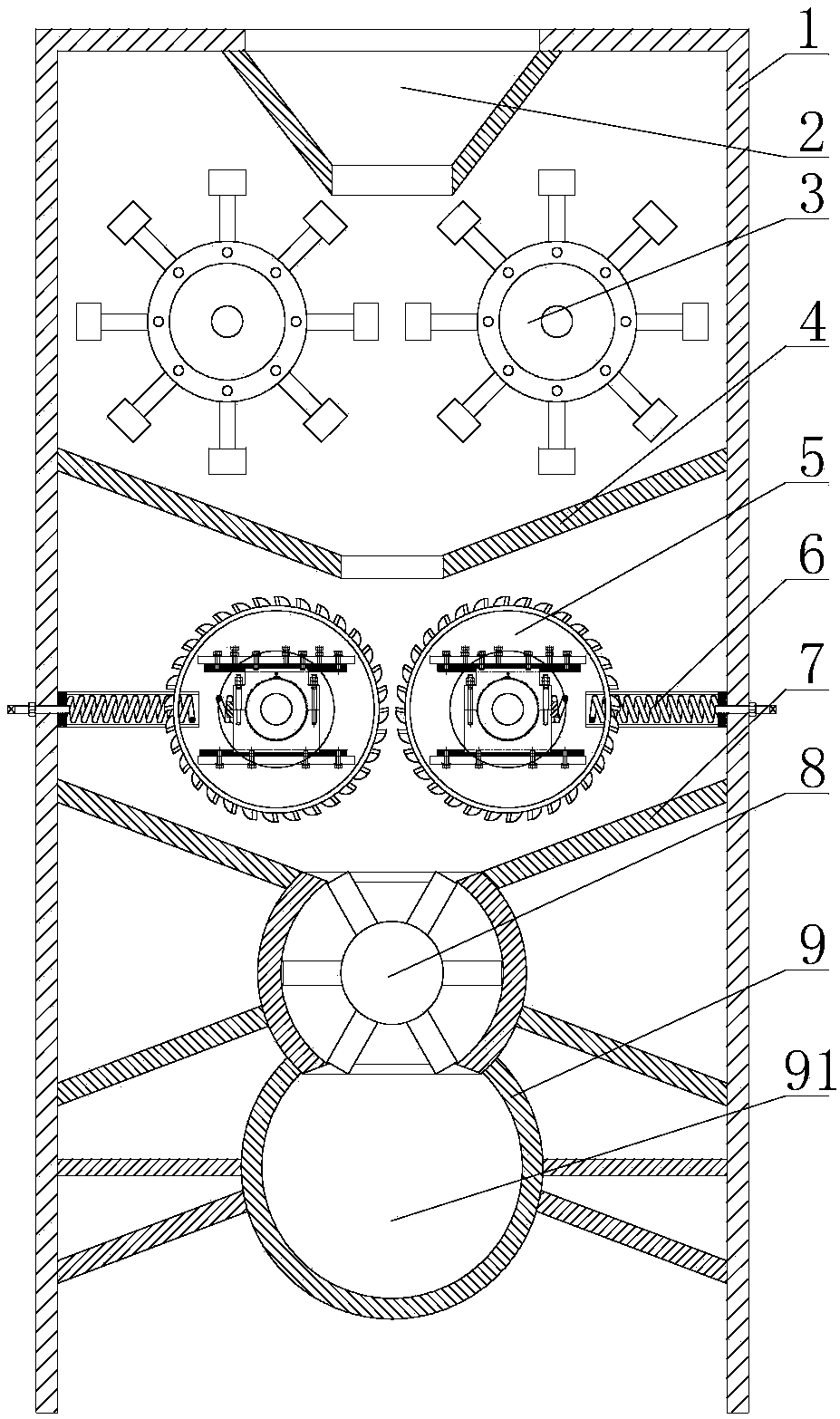

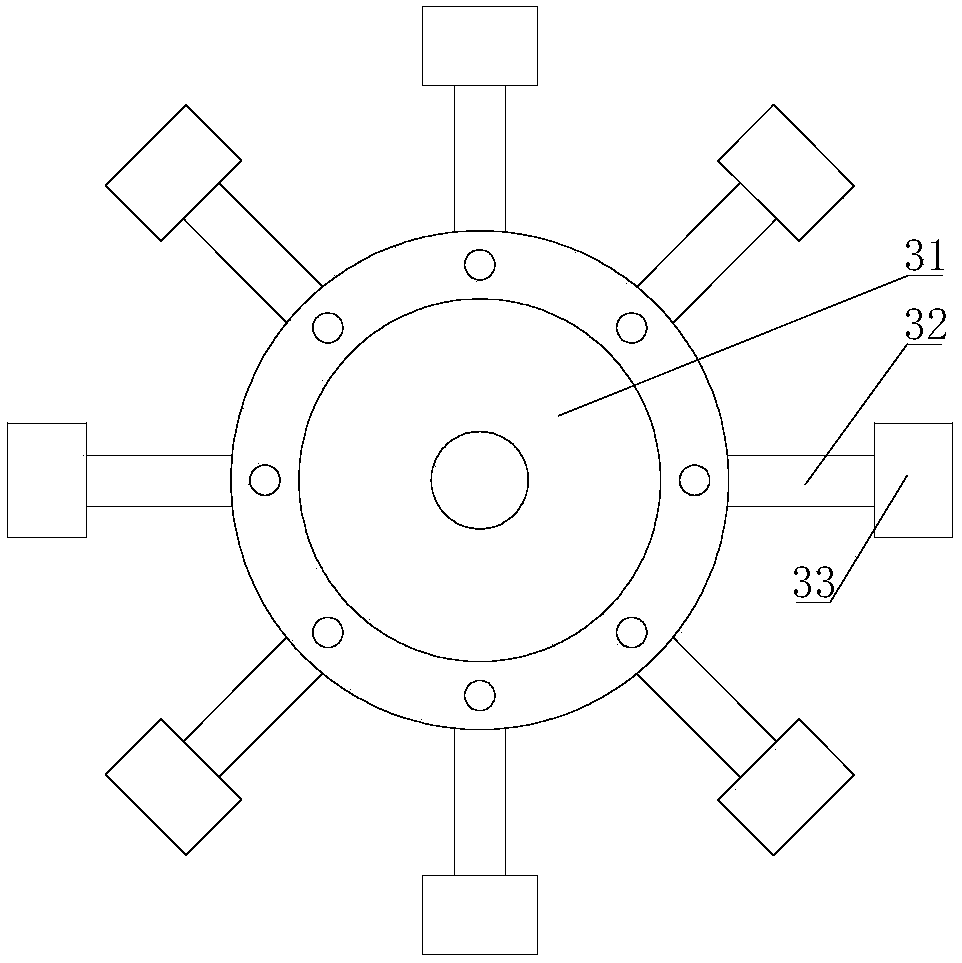

[0041] On the basis of Embodiment 1, the re-crushing device 18 includes a machine body 1, on which a feed hopper 2 is arranged, and a hammer grinding roller 3 and a crushing tooth roller 5 are arranged one above the other inside the body 1, so that A first collecting hopper 4 is arranged between the hammer grinding roller 3 and the crushing tooth roller 5, a second collecting hopper 7 is arranged below the crushing tooth roller 5, and a feeder 8 is connected below the second collecting hopper 7, The bottom of the feeder 8 is connected with a feed pipe 9, and one end of the feed passage 91 inside the feed pipe 9 is connected with a second blower fan 92, and the air outlet of the second blower blower 92 is provided with a device capable of generating Negatively charged ion bar 93, the other end of the feed passage 91 inside the feed pipe 9 communicates with the pulverized coal outlet on the body 1; A spacing adjustment device 6 for the spacing between the toothed rollers 5 .

...

Embodiment 3

[0044] On the basis of Embodiment 2, the air outlet of the second fan 92 is arranged obliquely, and the included angle β between the air outlet direction of the second fan 92 and the conveying direction of the material in the conveying channel 91 is 45°. ° to 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com