Backward warming system of boiler feed pump

A technology of boiler feed water pump and feed water pump, which is applied in the direction of controlling feed water, pump components, variable capacity pump components, etc., can solve problems such as high water pressure and easy bursting of pipelines, and achieve lower water pressure, save pipeline consumption, and improve maintenance efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

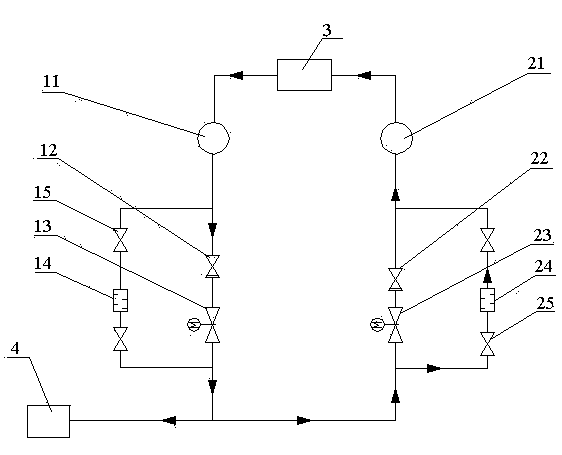

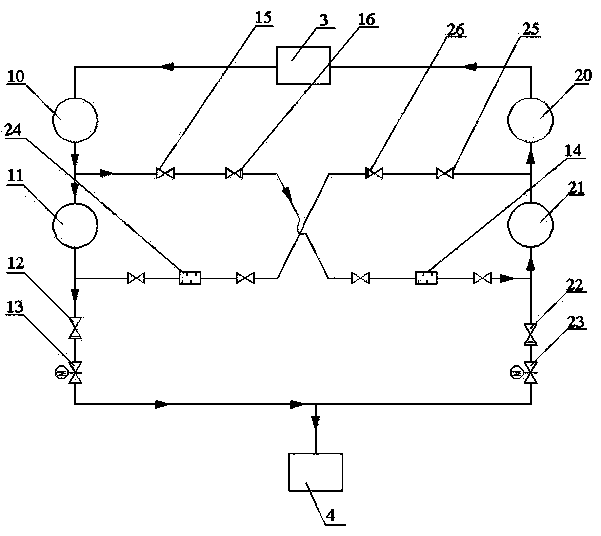

[0030] A boiler feed water pump heating system, such as figure 2 As shown, it includes a first pipeline and a second pipeline, and the first pipeline and the second pipeline are arranged in parallel between the deaerator 3 and the high pressure heater 4 . On the first pipeline, a first prepump 10 , a first feed water pump 11 , a first check valve 12 and a first electric valve 13 are sequentially connected in series from one end of the deaerator 3 . On the second pipeline, a second pre-pump 20 , a second feed water pump 21 , a second check valve 22 and a second electric valve 23 are connected in series from one end of the deaerator 3 . The inlets of the first prepump 10 and the second prepump 20 communicate with the deaerator 3 respectively, and the outlets of the first electric valve 13 and the second electric valve 23 communicate with the high pressure heater 4 . Wherein the first feedwater pump 11 and the second feedwater pump 21 are high-pressure pumps, and the first pre-...

Embodiment 2

[0037] Such as image 3 As shown, the difference from Embodiment 1 is that the pipeline between the first bypass check valve 16 and the first cut-off valve 15 located in the middle of the first bypass, and the second bypass check valve 26 and the second bypass check valve The pipelines between the second shut-off valves 25 in the middle of the bypass are merged into one common pipeline.

[0038] On the one hand, this setting can save space in the turbine room and make the layout of the turbine room more reasonable; on the other hand, it can save the amount of pipelines and reduce costs.

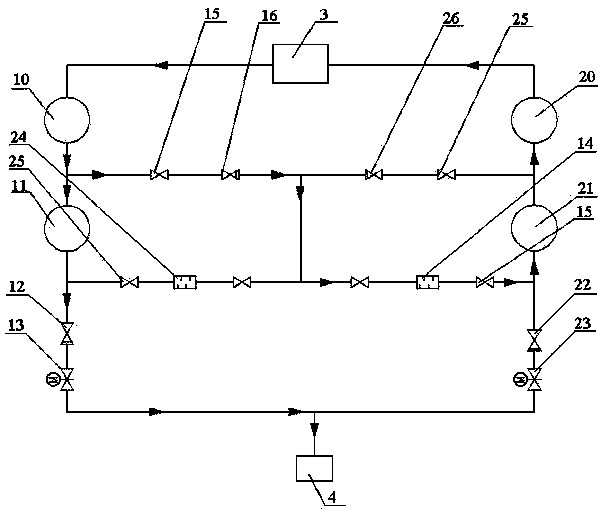

Embodiment 3

[0040] Such as Figure 4 As shown, the difference with Embodiment 1 is:

[0041] A first bypass check valve 16, a common throttling orifice 54 and three first cut-off valves 15 are arranged on the first bypass. The non-return valve 16, the common throttling orifice 54, the first cut-off valve 15, and the first cut-off valve 15 are sequentially arranged in series.

[0042] The second bypass includes three sections of pipelines: pipeline I, pipeline II and pipeline III. The pipeline I is connected between the outlet of the second prepump 20 and the outlet of the first bypass check valve 16, and a second cut-off valve 25 and a The second bypass check valve 26 .

[0043] Pipeline II is a pipeline connected between the outlet of the first bypass check valve 16 and the inlet of the first stop valve 15 in the middle of the first bypass, that is, this section of pipeline is the first bypass and the second bypass. public pipelines. The common orifice plate 54 on the pipeline II is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com