A kind of supported metal diatomic catalyst and its preparation method and application

A diatom and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of low ethanol selectivity and low conversion efficiency, and achieve high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: synthesis oxide carrier CeO 2

[0027] At 25°C, dissolve cerium nitrate in water to prepare a cerium nitrate solution with a concentration of 0.15 mol / L, add 0.15 mol / L sodium carbonate solution to the cerium nitrate solution, stir for 6 hours and then let stand for more than 12 hours; filter to obtain precipitate , after repeated washing with deionized water, dry in the air to obtain basic cerium carbonate; in N 2 and O 2 Under the atmosphere, basic cerium carbonate was calcined at 400°C for 3 hours to obtain the oxide support CeO 2 .

Embodiment 2

[0028] Embodiment 2: synthetic CeO 2 supported Pd catalyst

[0029] At 25°C, palladium nitrate was prepared into a 0.15 mmol / L Pd metal precursor aqueous solution, and HCl was added to adjust the isoelectric point of the solution to 5 to form a 2-membered coordination configuration. CeO 2 The carrier is dispersed in water, and the CeO is lifted by ultrasonic vibration for 5 minutes 2 The degree of dispersion of the carrier in the solution. The palladium nitrate solution is added in the above-mentioned support oxide solution by the method (injection speed 0.5ml / min) of peristaltic pump microsampling, makes it evenly dispersed on the surface of oxide support, after filtering, vacuum drying, in Calcined at 300°C in air for 4 hours to form CeO 2 Supported Pd diatomic catalysts.

[0030] CeO synthesized above 2 Loaded Pd catalyst, the mass percentage of Pd is 0.5wt.%, abbreviated as 0.5wt.%Pd 2 / CeO 2 .

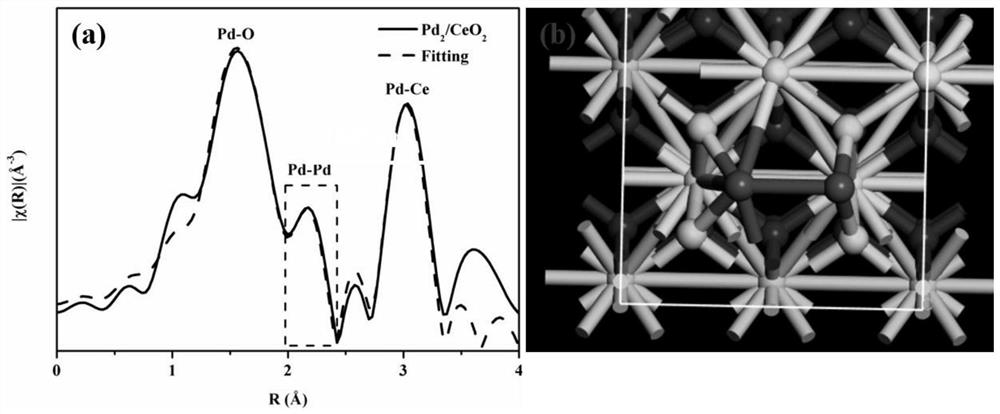

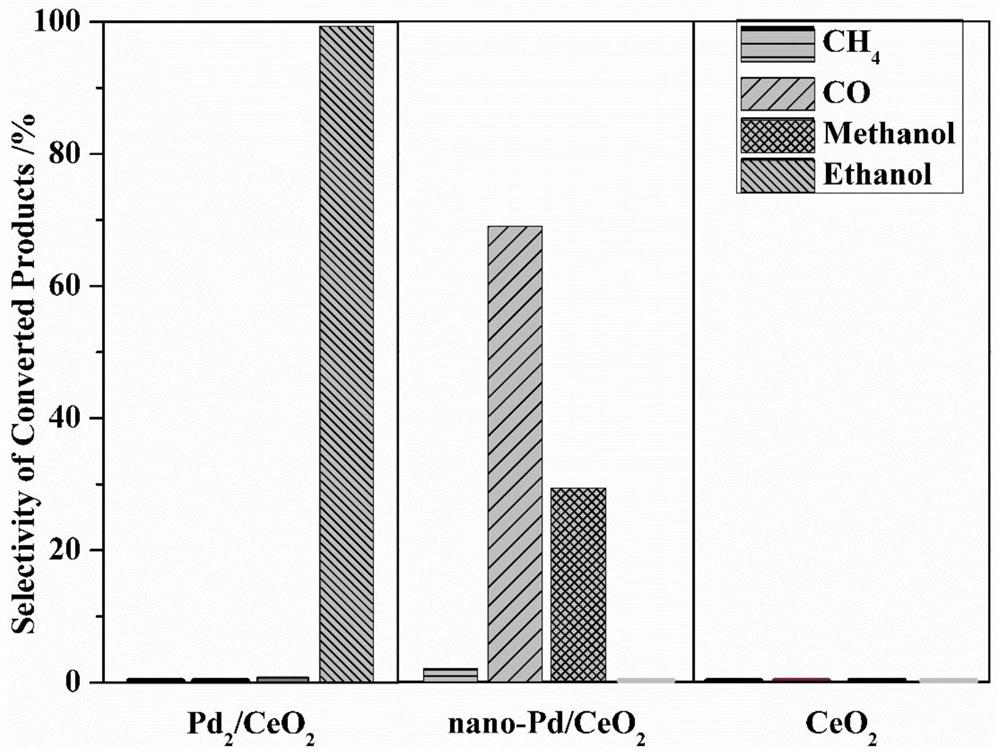

[0031] PD 2 / CeO 2 Extended X-ray Edge-Fine Adsorption Spectroscop...

Embodiment 3

[0038] Embodiment 3: synthetic CeO 2 Supported Pt catalyst

[0039] Synthetic method is similar to embodiment 1, and the catalyst that obtains is 0.8wt.%Pt 2 / CeO 2 .

[0040] After testing, the reaction pressure is 2MPa and H 2 / CO 2 Under the condition of ratio 3, 0.8wt.%Pt 2 / CeO 2 Catalyst to CO 2 The conversion rate was 14.2%, and the ethanol selectivity was 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com