Solution preparation device of solid material, and method and system for removing peroxide in epsilon-caprolactone synthesis system

A technology for mixing solid materials and materials, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve the problems of ε-caprolactone distillation, rectification and purification process safety hazards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

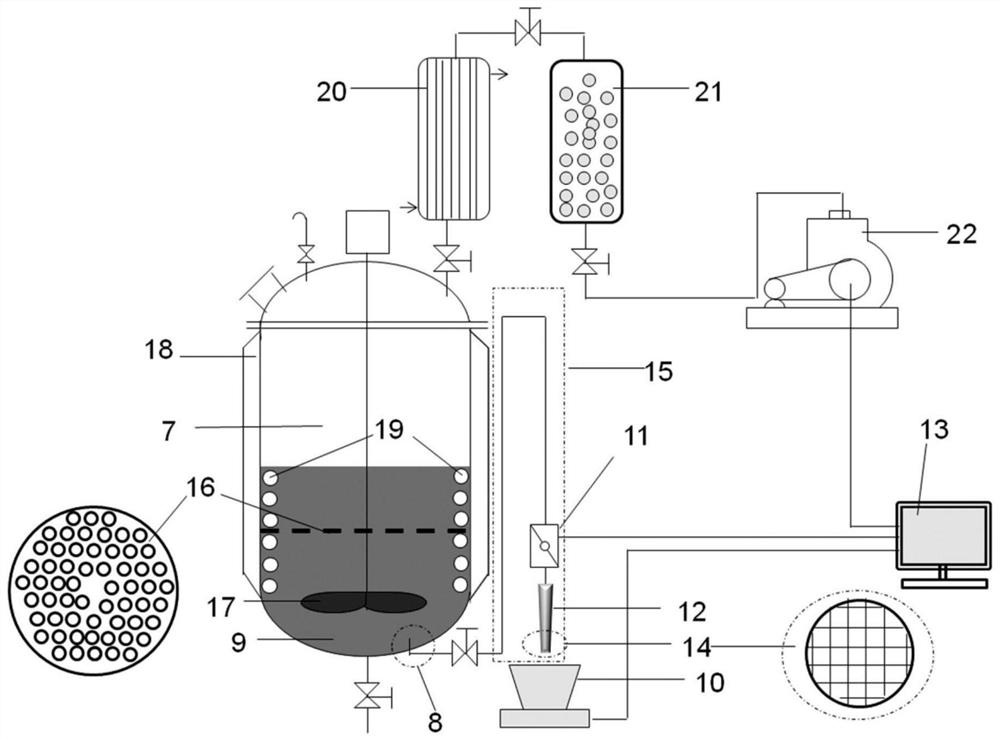

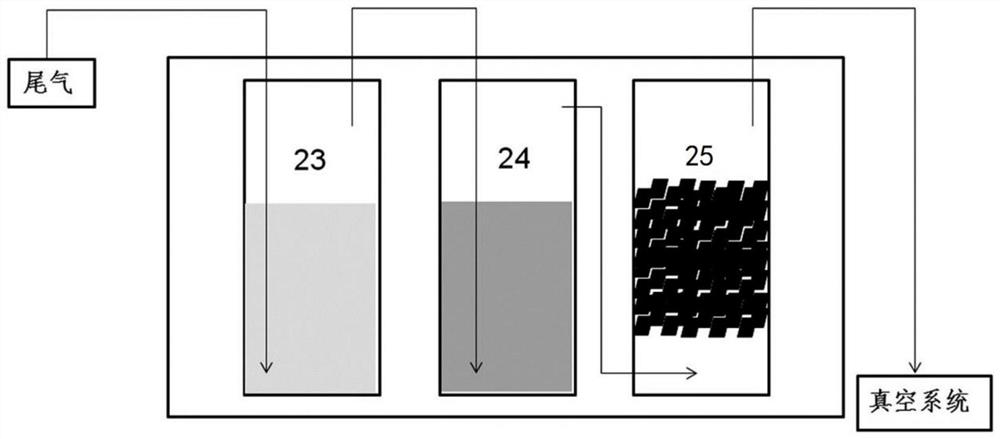

[0078] Reducing solution configuration:

[0079] First inject or suck 2kg of water into the 20L mixing tank cylinder (7), so that the liquid forms a liquid seal on the reducing solid material inlet (8). Open the vacuum system (5), the 1.5kg sodium bisulfite solid powder weighed by the weighing system is passed through the suction pipe (12) of the filter screen (14), sucked into the feed pipe, and passed through the "reverse U-shaped After the pipeline (15) is picked up, it contacts with the liquid seal solution, and then is sucked into the mixing tank cylinder (7). After adding 11.5 kg of water, turn on the stirring paddle, control the stirring speed at 50-150 RPM, and obtain a reducing sodium bisulfite aqueous solution with a concentration of 10% after stirring for 2 hours. During the stirring and dissolving process, a certain amount of water vapor and sodium bisulfite will be decomposed to produce acidic sulfur dioxide gas due to the exothermic dissolution. In order to prev...

Embodiment 2

[0082] Reducing solution configuration: first inject or suck 2kg of water into the mixing tank cylinder (7) with a capacity of 20L, so that the liquid forms a liquid seal on the reducing solid material inlet (8). Open the vacuum system (5), the 2kg sodium bisulfite solid powder weighed by the weighing system is passed through the suction pipe (12) equipped with the filter screen (14), sucked into the feed pipe, and passed through the "reverse U-shaped" After the pipeline (15) is raised, it contacts with the liquid seal solution, and then is sucked into the cylinder body of the mixing kettle (7). After adding 12 kg of water, turn on the stirring paddle, control the stirring speed at 50-150 RPM, and obtain a reducing sodium bisulfite aqueous solution with a concentration of 12.5% after stirring for 4 hours. During the stirring and dissolving process, a certain amount of water vapor and sodium bisulfite will be decomposed to produce acidic sulfur dioxide gas due to the exotherm...

Embodiment 3

[0085] Reducing solution configuration: first inject or suck 2kg of water into the mixing tank cylinder (7) with a capacity of 20L, so that the liquid forms a liquid seal on the reducing solid material inlet (8). Open the vacuum system (5), and the 2kg potassium bisulfite solid powder weighed by the weighing system is passed through the suction pipe (12) equipped with the filter screen (14), sucked into the feed pipe, and passed through the "reverse U-shaped" After the pipeline (15) is raised, it contacts with the liquid seal solution, and then is sucked into the cylinder body of the mixing kettle (7). After adding 12 kg of water, turn on the stirring paddle, control the stirring speed at 50-150 RPM, and obtain an aqueous solution of reducing potassium bisulfite with a concentration of 12.5% after stirring for 4 hours. During the stirring and dissolving process, due to dissolving heat, a certain amount of water vapor and potassium bisulfite will be decomposed to produce acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com