A method for improving the aroma quality of papermaking reconstituted tobacco leaves in the papermaking and forming section

A technology for reconstituting tobacco leaves and forming sections is applied in the field of improving the aroma quality of the reconstituted tobacco leaves by the papermaking method, and can solve the problems that the sensory quality of the reconstituted tobacco leaves is not significantly improved, the nozzles of the coating pipes are blocked, the miscellaneous gas and the irritation are obvious, etc. Chemical application, reduced usage, good product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

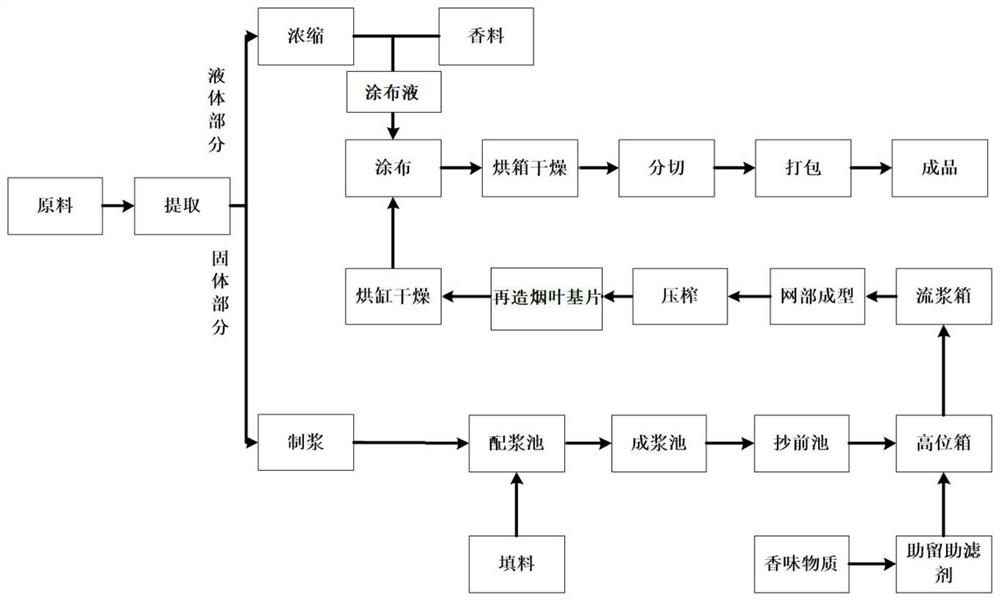

[0022] figure 1 Shown is the process flow for the preparation of papermaking reconstituted tobacco leaf products with flavoring substances added in the forming section, including the following steps:

[0023] (1) Prepare raw materials for preparing reconstituted tobacco leaves, such as tobacco leaves, tobacco stems, etc.;

[0024] (2) extract raw material with solvent, then solid-liquid separation;

[0025] (3) The separated solid part is used for pulping, and the liquid part is concentrated and added with spices to prepare a coating solution;

[0026] (4) The prepared slurry is sent to the slurry mixing tank, and fillers are added, and other plant slurry can also be mixed in if necessary, and the slurry is obtained and sent to the slurry mixing tank for storage;

[0027] (5) In the copy forming section, the slurry in the slurry tank is sent to the pre-print tank, and then sent to the high-level box. At the same time, the fragrance substance is added to the retention and dra...

Embodiment 2

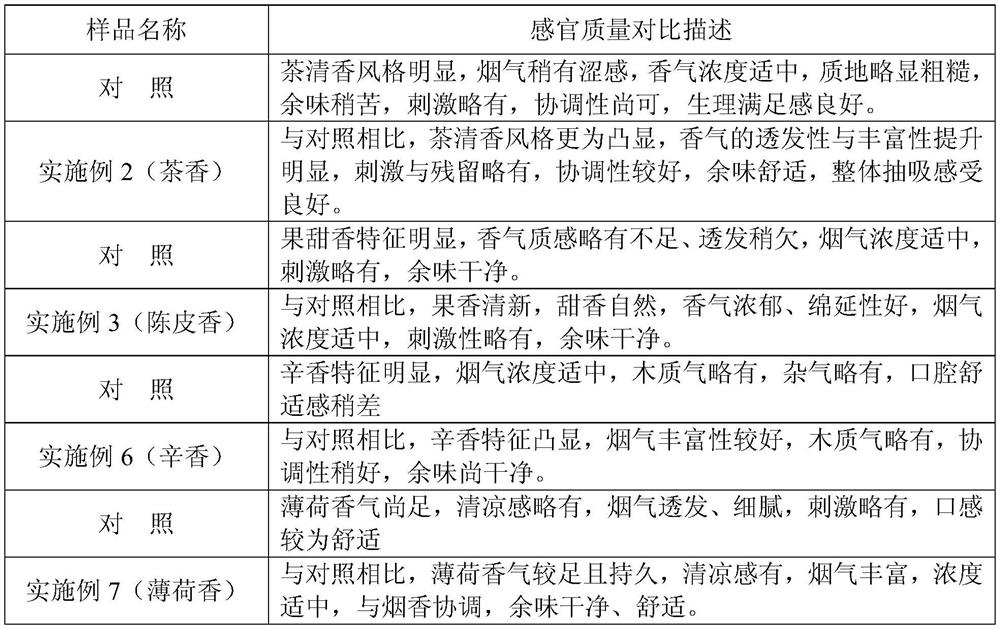

[0031] Applied to the method for improving the aroma quality of reconstituted tobacco leaves in the copying and molding section, the process steps of the method are the same as those in Example 1, except that the aqueous retention and drainage aid solution prepared in step (5) is different. Present embodiment is that 10.0kg chitosan is dissolved in 1000L tap water, is mixed with the retention and drainage aid aqueous solution that mass concentration is 1.00%, then gets the green tea superfine powder 20.0kg that particle diameter is 100 μ m respectively, and particle diameter is 100 μ m 20.0kg of Huilong tea superfine powder and 5.0kg of O / W type microcapsules embedded with tea essential oils with a particle size of 100 μm are dissolved in the above-mentioned aqueous solution of retention and drainage aids and stirred evenly to obtain a retention aid with dispersed fragrance substances. Aqueous solution of filter aid. The tea fragrance reconstituted tobacco finished product is ...

Embodiment 3

[0033] Applied to the method for improving the aroma quality of reconstituted tobacco leaves in the copying and molding section, the process steps of the method are the same as those in Example 1, except that the aqueous retention and drainage aid solution prepared in step (5) is different. In this embodiment, 0.50kg sodium carboxymethylcellulose is dissolved in 1000L tap water, and it is prepared into an aqueous solution of retention and drainage aid with a mass concentration of 0.05%. The O / W type microcapsule 5.0kg that diameter is 50 μm is embedded with dried orange peel essential oil is dissolved in above-mentioned retention and drainage aid aqueous solution, stirs, obtains the retention and drainage aid aqueous solution of dispersing fragrance substance. The dried tangerine peel fragrant reconstituted tobacco leaf product is prepared through the papermaking method reconstituted tobacco leaf product preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com