Thin film transistor and manufacturing method thereof, array substrate, display panel and equipment

A technology of thin film transistor and bottom surface, which is applied in the fields of thin film transistor and its manufacturing method, array substrate, display panel and equipment, and can solve the problems of uneven screen flicker of display device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present application are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary, are only for explaining the present application, and should not be construed as limiting the present application. In addition, various specific process and material examples are provided herein, but one of ordinary skill in the art may recognize the use of other processes and / or the use of other materials.

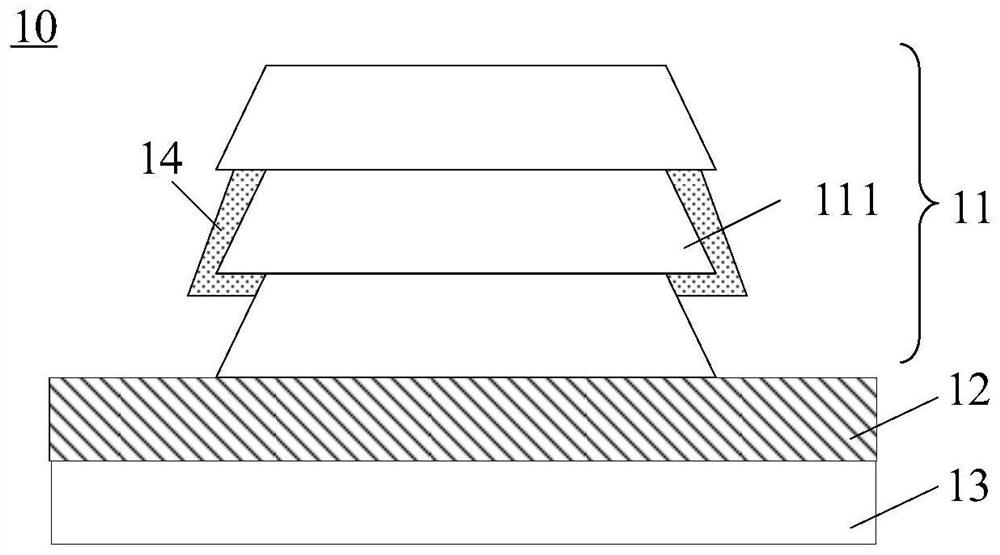

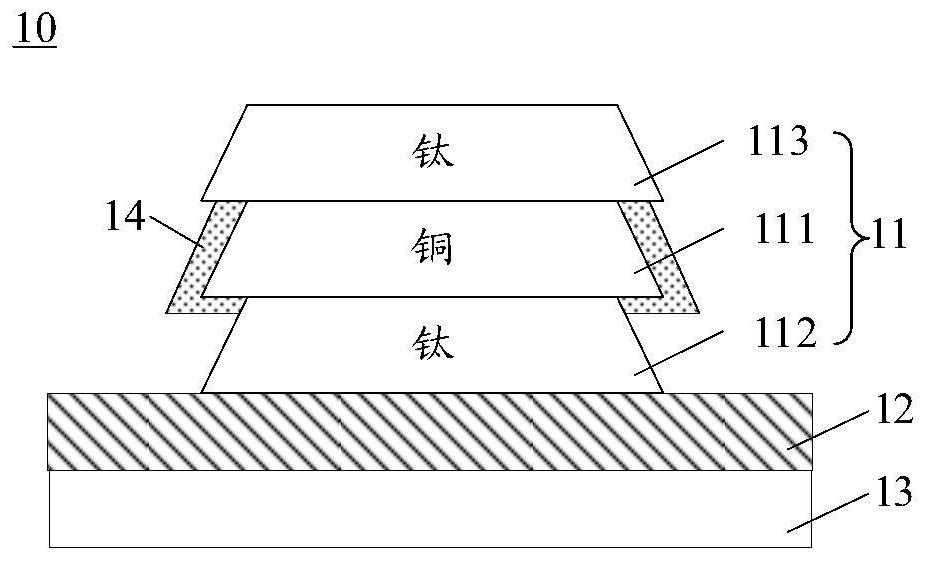

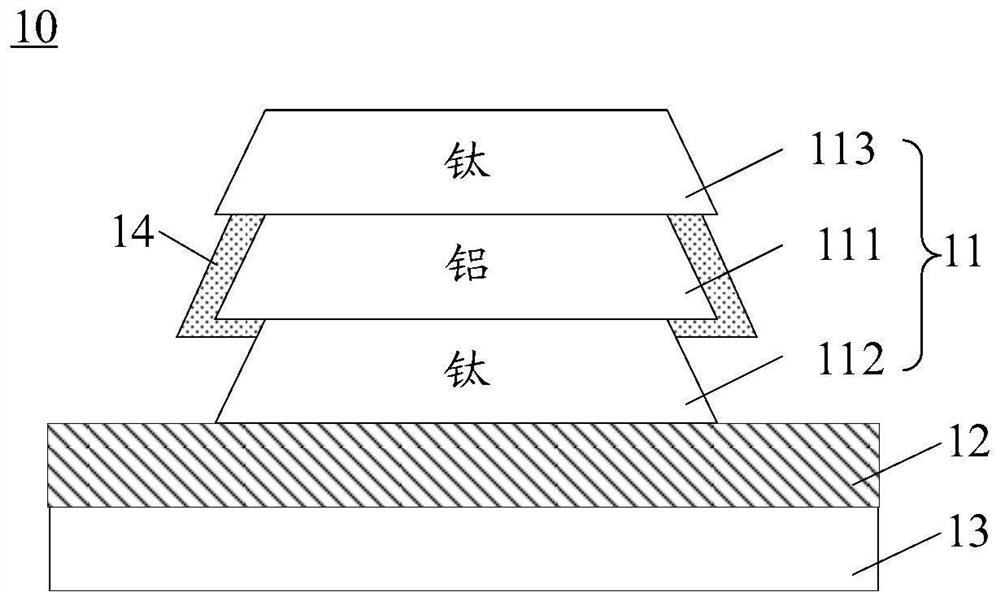

[0027] see figure 1 , the thin film transistor 10 includes a gate 11 , a gate insulating layer 12 , an active layer 13 and a protection layer 14 . The gate 11 is disposed on the side of the gate insulating layer 12 facing away from the active layer 13 , the grid 11 has a sheet resistance less than or equal to a preset grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com