Tunnel construction method

A technology for tunnel construction and tunneling, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as karst columns/collapsed columns are easy to collapse again, tunnel threats, and grouting bodies are not firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

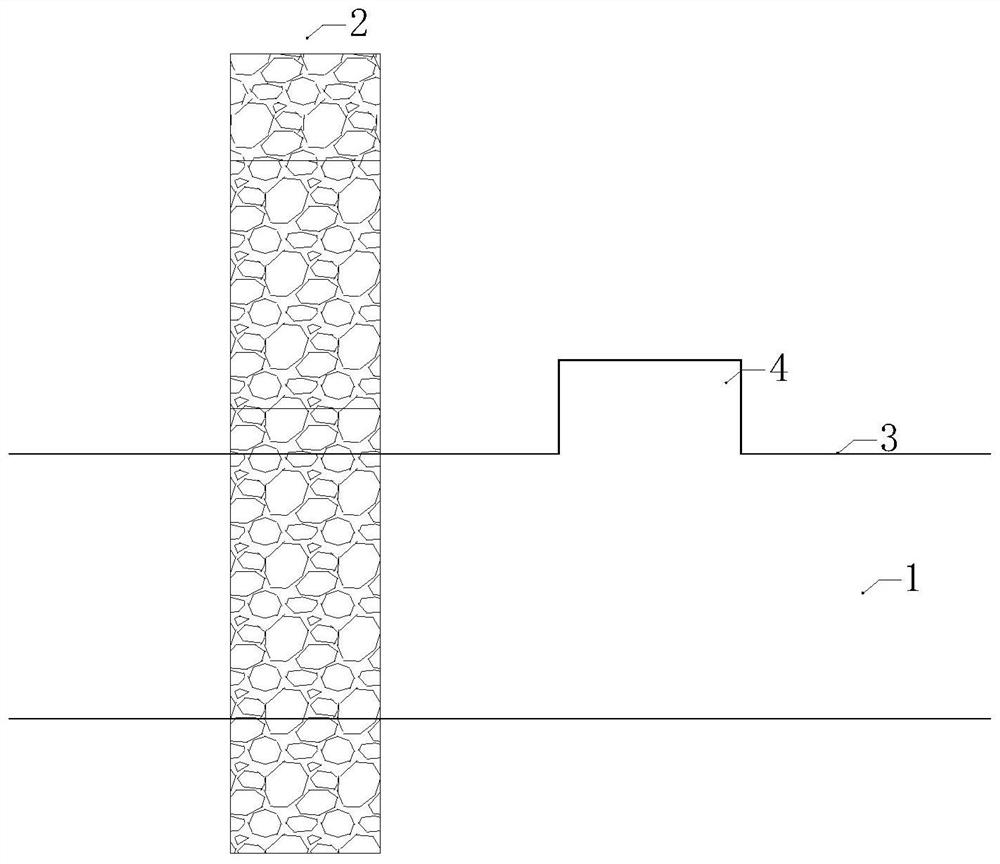

[0036] A tunnel construction method, comprising the following construction steps: S1, such as Figure 1-2 , detect the intersection position of the collapse column 2 and the tunnel 1 in advance, and the diameter of the collapse column at the intersection position; when the tunnel excavation is close to the collapse column, that is, at a distance ahead of the collapse column, the tunnel roof 3 is expanded to form the construction chamber 4;

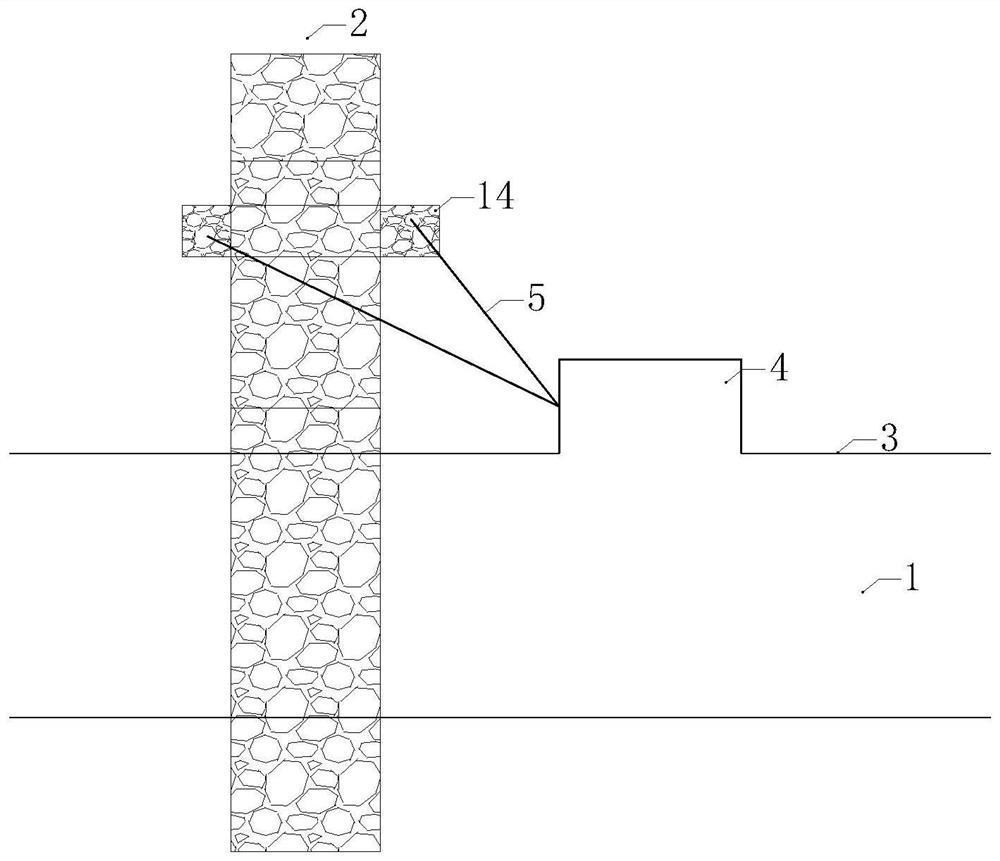

[0037] S2, such as image 3 , in the construction chamber, construct the blast hole 5 toward the collapsed column 2, blast the complete rock mass around the collapsed column at a certain height above the tunnel to form an annular artificial blasting area 14, and the collapsed column after blasting is in the shape of a nail;

[0038] S3, such as Figure 4 From the construction chamber 4 to the front of the tunnel 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com