Construction method for pouring bearing platform by adopting reverse mounting form boards in narrow space

A construction method and technology in space, applied in construction, infrastructure engineering and other directions, can solve the problems of affecting traffic, large damage to existing roads, large excavation size of foundation pits, etc., to reduce the number of use, save resources, compress Effect of excavation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

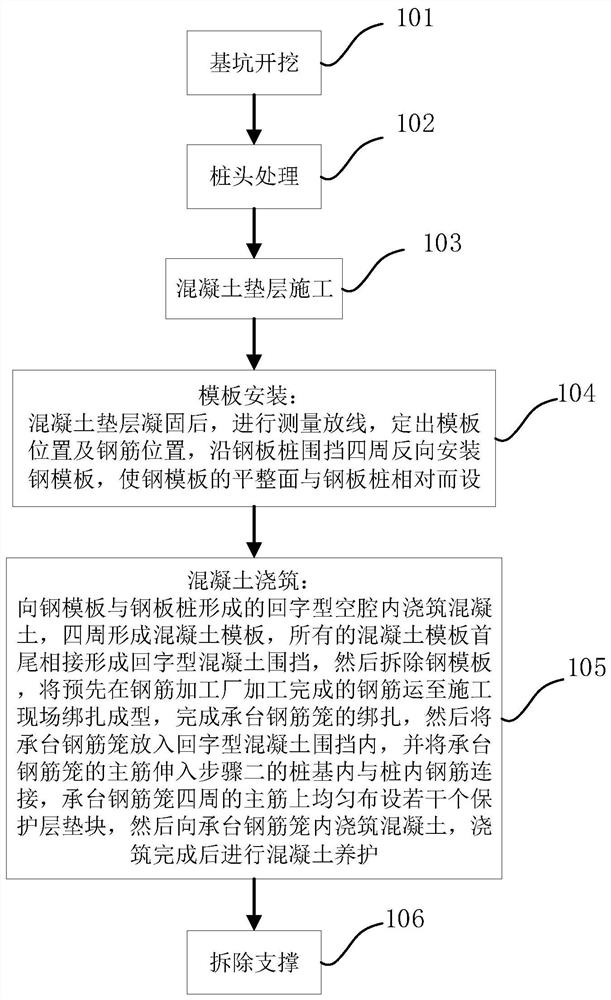

[0033] In order to solve the problem that the traditional caps construction method has a large damage range to the existing roads and a large excavation size of the foundation pit, which seriously affects the traffic, the present invention provides a construction method of pouring caps using reverse formwork in a narrow space methods such as figure 1 shown, including the following steps:

[0034] Step 101: Excavation of foundation pit

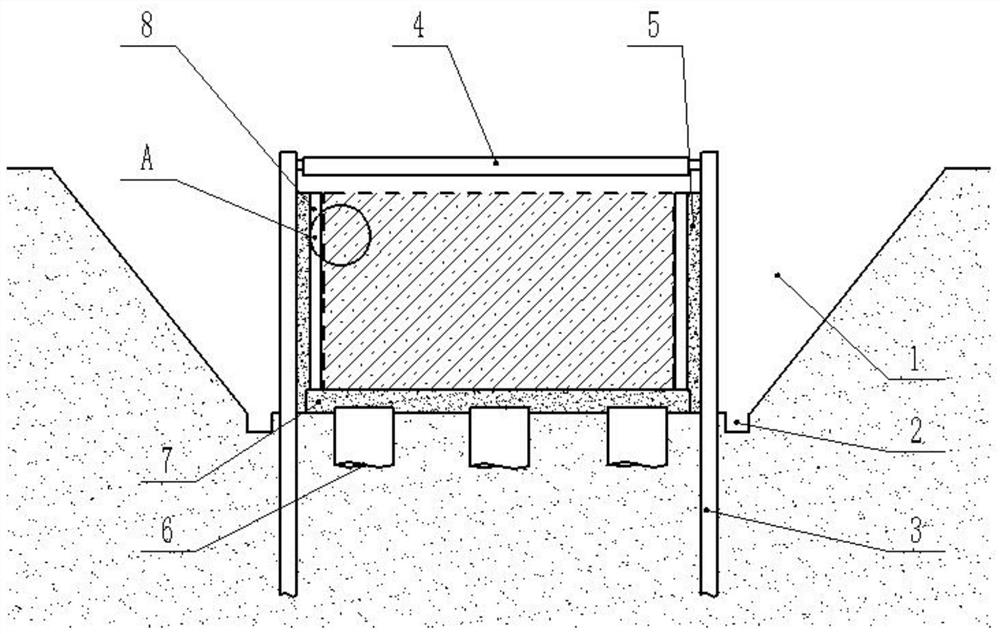

[0035] Such as figure 2 and Figure 4 As shown, the excavation depth, slope and excavation point of the foundation pit 1 are designed according to the size of the cap, and the excavator is used as the main force and the labor is supplemented. 3. Install purlins and supports 4 in the enclosure surrounded by steel sheet piles 3, and the lowest point of the supports is higher than the elevation of the top surface of the cap;

[0036] Excavate the foundation pit 1 to the design elevation, arrange at least one sump at the corner of the foundati...

Embodiment 2

[0050] On the basis of Example 1, concrete is poured into the back-shaped cavity formed by the steel formwork 8 and the steel sheet pile 3 as described in step five, and the poured concrete is plain concrete, and the grade of plain concrete is not higher than that of the cap concrete label.

[0051] Specifically, plain concrete is a structure made of concrete without reinforcement or without reinforced reinforcement. Since the cap is to bear the load transmitted by the pier body, the strength requirements for the concrete are higher than those for the concrete formwork 8 .

Embodiment 3

[0053] In particular, the inner edge of the back-shaped concrete enclosure described in step five is the outer edge of the cap. What needs to be specially explained here is that the back-shaped concrete enclosure surrounded by the concrete formwork 5 is similar to the steel formwork in the traditional platform construction method. The difference is that in this embodiment, the inner edge of the back-shaped concrete enclosure is used as the outer edge of the cap to replace the traditional steel form 8, which avoids the removal of the steel form after the cap is poured , there is no need to reserve the demolition space of the steel formwork, thereby compressing the excavation size of the foundation pit, reducing the scope of damage to the existing roads, thereby reducing the number of steel sheet piles used, saving resources, and having high economic efficiency .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com