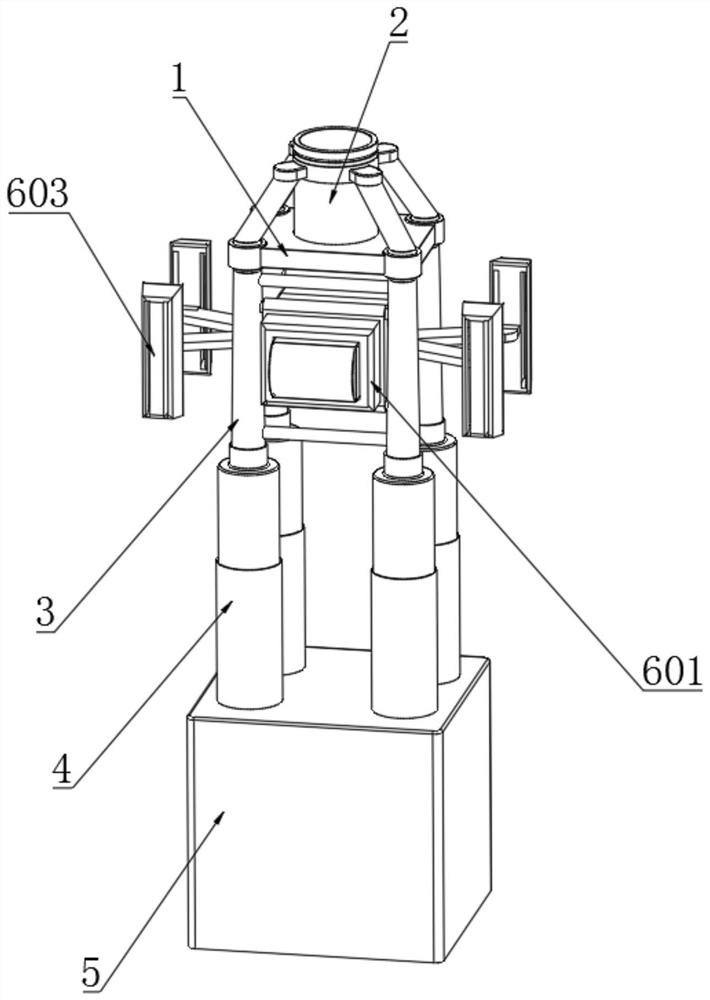

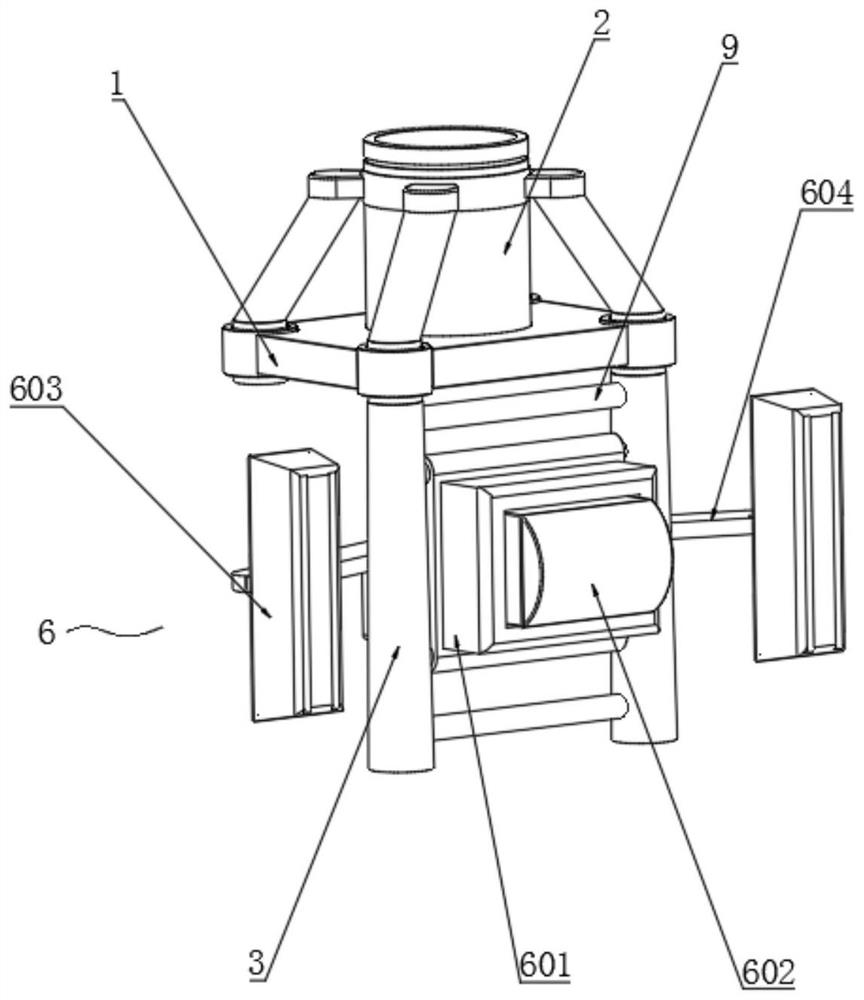

Offshore wind turbine jacket foundation structure

A technology for infrastructure and offshore wind turbines, applied in infrastructure engineering, underwater structures, water conservancy projects, etc., which can solve the problems of easy shaking and inability to realize pressure relief buffer protection of jackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] Example 2: See Figure 5 with 6 , the bottom end of the steel pipe pile 4 is installed with a concrete abutment 5, and the compensation component 7 includes a compensation chamber 701, a material injection hollow groove 702, a pressure sensor 703 and a concrete support 704, and the inside of the foundation plate 1 is installed with a concrete support 704, A compensation chamber 701 is installed at the bottom of the concrete support 704 corresponding to the top of the concrete abutment 5, and a hollow groove 702 is provided in the middle of the interior of the concrete support 704, and the inner bottom of the compensation chamber 701 corresponds to the bottom of the compensation chamber 701 Embedded with a pressure sensor 703, when the bottom end of the steel pipe pile 4 collapses at the position of the concrete abutment 5, through the collection of force data difference of multiple pressure sensors 703, through the concrete support 704 in the steel pipe pile 4 The inje...

Embodiment 3

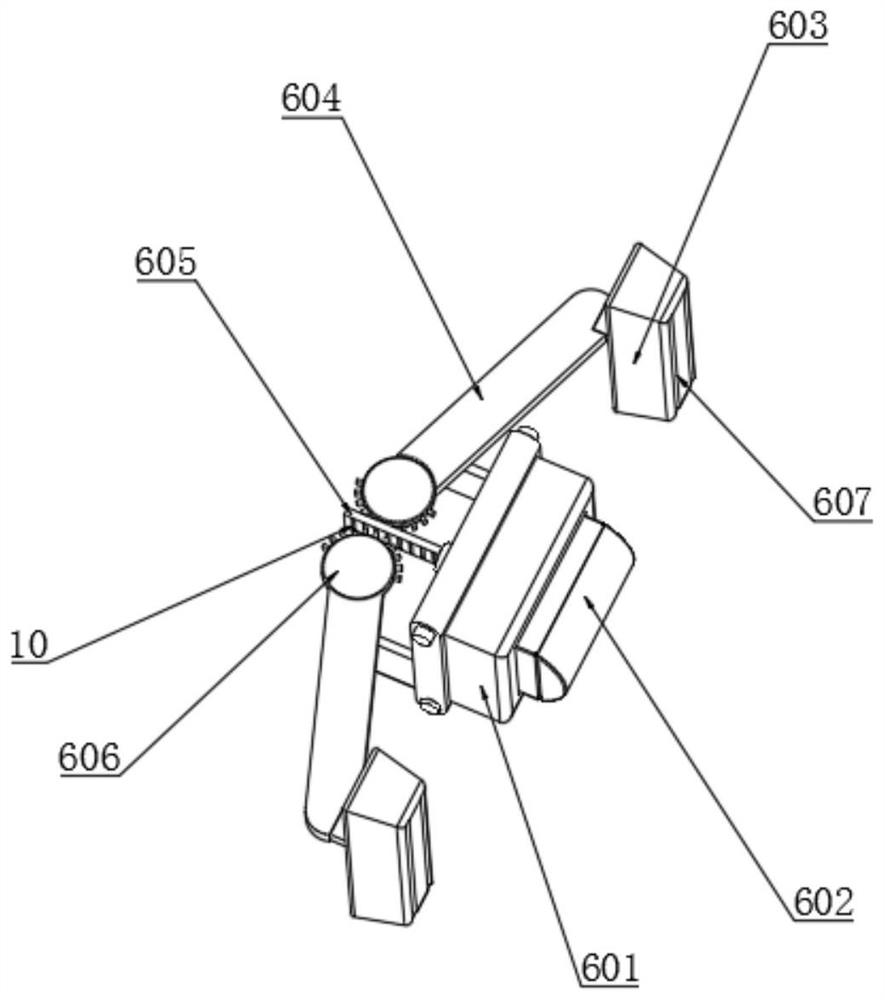

[0039] Example 3: See Figure 7 with 8 , the middle part of the top of the base plate 1 is embedded with a tower fixing seat 2, and the outside of the tower fixing seat 2 is fixedly connected with the base plate 1 through a fixing component 8, which includes a main brace 801, a rubber pad The ring 802 and the drying support ring 803 are fixedly connected between the outside of the tower fixing seat 2 and the base plate 1 through the main diagonal brace 801, and the inside of the tower fixing seat 2 is sleeved with a rubber pad retaining ring 802, and the rubber pad retaining ring 802 One side is socketed with a drying support ring 803, and the exterior of the tower fixing seat 2 can be supported through a plurality of main diagonal braces 801 at the base plate 1, and the tower tube is supported by the rubber pad retaining ring 802 and the drying support ring 803. The inner wall of the fixing seat 2 is tightened so that it fits more closely with the bottom end of the fan.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com