Production line and production process for polyvinyl chloride paste resin model head

A polyvinyl chloride paste and production line technology, applied in the direction of coating, can solve the problems of easy shaking and waste, and achieve the effects of improving molding quality, avoiding waste, fixing stability and high safety in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

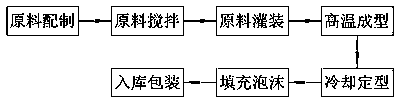

[0056] Such as figure 1 As shown, the polyvinyl chloride paste resin mannequin production line includes the following steps set up along the production process of the polyvinyl chloride paste resin mannequin 100:

[0057] A stirring device 200 for stirring the polyvinyl chloride paste resin raw material;

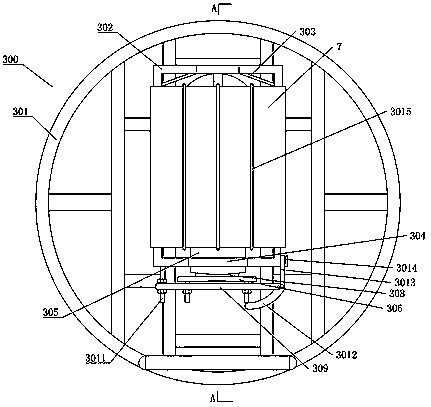

[0058]The mold placement frame 400 for placing the model head mold 300, the model head mold 300 includes a base 301 and a mounting frame 302 arranged up and down together, and the two ends of the mounting frame 302 are respectively fixed with a conical limiting frame 303 and a coaxially arranged Annular limit plate 304, conical limit frame 303 and annular limit plate 304 are jointly provided with a mold body 305, and the outer side of annular limit plate 304 is provided with a first locking mechanism for fixing the mold body 305, the first locking mechanism includes The locking plate 306 vertically arranged on the outside of the annular limiting plate 304, the end of the mo...

Embodiment 2

[0075] The production process of polyvinyl chloride paste resin model head comprises the following steps:

[0076] S1, using the above-mentioned stirring device 200 to stir the polyvinyl chloride paste resin raw material;

[0077] S2, placing a plurality of above-mentioned model head molds 300 on the mold placement frame 400, and adding a certain amount of polyvinyl chloride paste resin raw materials to the model head molds 300;

[0078] S3, putting the model head mold 300 into the above-mentioned high-temperature molding device 500 for heating;

[0079] S4, taking out the heated mannequin head mold 300, and then placing it in the above-mentioned cooling and shaping device 600 for cooling and shaping;

[0080] S5, pour filling material into each polyvinyl chloride paste resin mannequin 100 one by one, and then fix the fixed base 301 on the bottom of the polyvinyl chloride paste resin mannequin 100, after the foaming and curing of the filling material is completed, the polyvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com